Z.ZAG

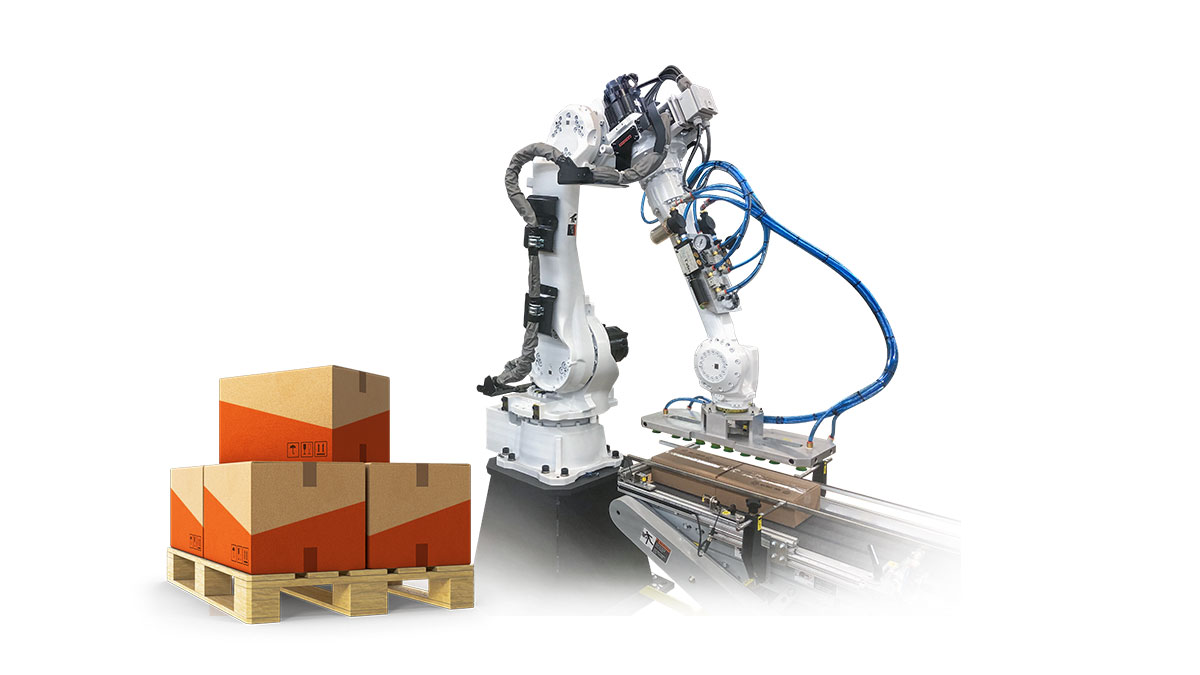

Robotic Palletizer/Depalletizer

Our Z.Zag robotic palletizer will automate your pallet loading and unloading processes, eliminating the risk of injury from employees manually placing cases onto pallets while also increasing efficiency and reducing expenses.

This automated system uses a robotic arm to meticulously stack and organize various items, including boxes, bags, cans, bottles, or crates, onto pallets.

The machine works like a well-oiled team with four key components:

- The Robotic Arm: This tireless worker acts as the muscle, precisely moving and rotating to pick and place items.

- The Gripper: Think of it as the adaptable hand. It attaches to the arm’s end and uses suction cups, clamps, or magnets to securely grasp different items.

- The Conveyor: This acts as the moving walkway, transporting items to and from the palletizing area.

- The Control System: The mastermind behind the operation, it coordinates the entire process based on pre-programmed patterns or manual input.

The palletizing process itself is a ballet of coordinated movements:

- Feeding the System: Items are loaded onto the conveyor, either automatically by a feeder or by a human operator.

- Item Detection: A sensor on the conveyor acts as a watchful eye, identifying the presence and size of each item.

- Strategic Placement: The control system, the mastermind, calculates the optimal position and orientation for each item on the pallet, considering the overall pattern and item shape.

- Pick and Place: The robotic arm, with pinpoint accuracy, aligns the gripper with the item, picks it up, and then moves and rotates to precisely place it on the designated spot on the pallet.

- Repeat and Replenish: The robotic arm tirelessly repeats this process until the pallet is full or all the items are used.

- Pallet Handover: Once a pallet is complete, a forklift or another conveyor whisks it away, and a new pallet takes its place, ready for the cycle to begin again.

Let us customize a solution for your palletizing needs with our end-of-line robotic palletizers for cases, trays, bags and containers.

Videos

Features:

- Highly versatile, the Z.Zag robotic palletizer is ideal for case palletizing, bag palletizing, order picking and many logistical tasks for end-of-line or distribution center automation.

- High-performance, 5-axis robot with 80 kg payload capacity.

- Impressive 3,291 mm vertical reach, combined with 2,061 mm horizontal reach, enables palletizing loads up to 2,413 mm tall.

- Internally routed airlines and cables from base to end-of-arm tool maximize reliability.

- Cable installation tube in the base of the robot facilitates fieldbus routing to the robot upper arm and/or gripper.

- NSF-H1 certified food-grade lubricant option available for food or consumer product packaging environment.

- Compact base and slim-arm design of the MPL80 II is ideally suited for minimum floorspace installation requirements.

- Highly customizable to each palletizing system.

*Rates subject to package style, type and size

Our Z.ZAG is suited for all industries as your go to drop/gravity case or tray packing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features:

- Highly versatile, the Z.Zag robotic palletizer is ideal for case palletizing, bag palletizing, order picking and many logistical tasks for end-of-line or distribution center automation.

- High-performance, 5-axis robot with 80 kg payload capacity.

- Impressive 3,291 mm vertical reach, combined with 2,061 mm horizontal reach, enables palletizing loads up to 2,413 mm tall.

- Internally routed airlines and cables from base to end-of-arm tool maximize reliability.

- Cable installation tube in the base of the robot facilitates fieldbus routing to the robot upper arm and/or gripper.

- NSF-H1 certified food-grade lubricant option available for food or consumer product packaging environment.

- Compact base and slim-arm design of the MPL80 II is ideally suited for minimum floorspace installation requirements.

- Highly customizable to each palletizing system.

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Z.ZAG is suited for all industries as your go to drop/gravity case or tray packing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

Z.ZAG

Robotic Palletizer/Depalletizer

Videos

Our Z.Zag robotic palletizer will automate your pallet loading and unloading processes, eliminating the risk of injury from employees manually placing cases onto pallets while also increasing efficiency and reducing expenses.

Let us customize a solution for your palletizing needs with our end-of-line robotic palletizers for cases, trays, bags and containers.

Features:

- Highly versatile, the Z.Zag robotic palletizer is ideal for case palletizing, bag palletizing, order picking and many logistical tasks for end-of-line or distribution center automation.

- High-performance, 5-axis robot with 80 kg payload capacity.

- Impressive 3,291 mm vertical reach, combined with 2,061 mm horizontal reach, enables palletizing loads up to 2,413 mm tall.

- Internally routed airlines and cables from base to end-of-arm tool maximize reliability.

- Cable installation tube in the base of the robot facilitates fieldbus routing to the robot upper arm and/or gripper.

- NSF-H1 certified food-grade lubricant option available for food or consumer product packaging environment.

- Compact base and slim-arm design of the MPL80 II is ideally suited for minimum floorspace installation requirements.

- Highly customizable to each palletizing system.

*Rates subject to package style, type and size

Our Z.ZAG is suited for all industries as your go to drop/gravity case or tray packing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features:

- Highly versatile, the Z.Zag robotic palletizer is ideal for case palletizing, bag palletizing, order picking and many logistical tasks for end-of-line or distribution center automation.

- High-performance, 5-axis robot with 80 kg payload capacity.

- Impressive 3,291 mm vertical reach, combined with 2,061 mm horizontal reach, enables palletizing loads up to 2,413 mm tall.

- Internally routed airlines and cables from base to end-of-arm tool maximize reliability.

- Cable installation tube in the base of the robot facilitates fieldbus routing to the robot upper arm and/or gripper.

- NSF-H1 certified food-grade lubricant option available for food or consumer product packaging environment.

- Compact base and slim-arm design of the MPL80 II is ideally suited for minimum floorspace installation requirements.

- Highly customizable to each palletizing system.

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Z.ZAG is suited for all industries as your go to drop/gravity case or tray packing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.