Packaging Machines for Wisconsin Businesses

Wisconsin has several things to offer, be it the small-town fun vibes, outdoor activities, or cosmopolitan flair. Some of its exciting cities and towns are Bayfield, Madison, and Milwaukee with their cultural sites, museums, and breweries. To start with, head over to the Devil’s Lake State Park near Baraboo. It’s Wisconsin’s most popular state park, mostly due to the traction brought by its dramatic 500-foot russet bluffs that surround a 360-acre lake. Want to go on a scenic ride? The Wisconsin Great River Road is the place for you. It’s flanked by 400-foot sandstone bluffs and historic small river towns.

As you go along the road, you can see people boating, birding, and fishing. River towns also have some interesting things to offer so you may want to check them while you can. Another amazing Wisconsin destination is the Milwaukee Art Museum where you can see arts from the 13th century to the present. It’s strikingly beautiful architecture and design have made it become the city’s visual icon. Are you a certified cheese lover? Green County has the best cheese in Wisconsin. So, make sure to check out either (or both) Roth Cheese and Baumgartner’s Cheese Store & Tavern in Monroe.

Granule Packaging Machines

Every product needs packaging, be it fresh produce, confectionery, baked products, household goods, motor parts and so much more. And when it comes to certain things like chemical fertilizers, medical treatment, and so on, an automatic granule packaging machine is the go-to solution. Granule packaging machines are used to load granular items as per the desired weight into the container and then seal. Even for automatic granule fillers, they can be classified into various types according to their mechanical rating, type of measuring cup, electronic scale, and the feeding method.

But while there are tons of kinds of granule packaging machines, they serve the same primary purpose, which is to dispense the products into the container with accuracy, speed, and consistency. Nonetheless, these packaging machines specifically designed for granules undeniably offer great benefits such as:

1. Help improve labor productivity as these machines are much faster than a manual system while also boosting the filling efficiency.

2. Reduce labor workload, which in turn, improves the working conditions of employees as opposed to manually packaging large volume and heavy products.

3. Some granular products can negatively affect the health of people especially with constant exposure, something that’s bound to happen during manual packaging. With an automated granule packaging machine, such health risks can be avoided, significantly increasing the safety of the workers.

4. Granule packaging machines can handle your desired production needs, whereas, with manual packaging, the quality isn’t a guarantee since human workers are vulnerable to making errors.

5. Ensure product hygiene, which is very important specifically for food products. Plus, depending on the law, some products cannot be packaged manually as it can contaminate the products. By automating your granule packaging, you can eliminate human contact, ensuring hygiene quality.

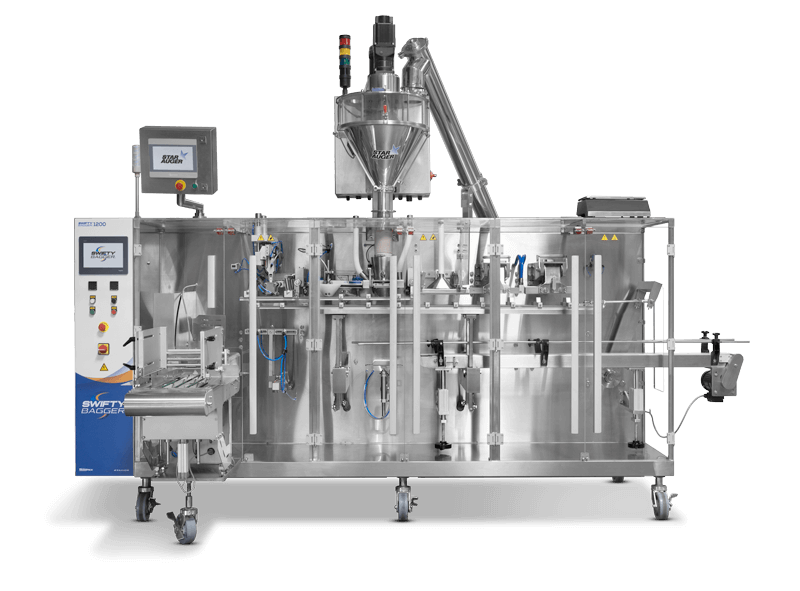

Star Auger Filler for your granule packaging needs

Paxiom prides itself as a trustworthy source of packaging machines and systems that cater to virtually all levels of packaging. When it comes to handling granular products, we have the Star Auger, a servo-driven filling machine that provides precision, speed, and versatility. Constructed to match your unique product requirements, we have created two models of our Star Auger: the 100 and 200 versions. Its standard features include stainless steel construction and quickly removable hopper for easy cleaning and maintenance.

Moreover, both models of Star Auger come with a self-adjusting screw and level sensing logic to provide reliable and consistent weights. Equipped with a hinged hopper that’s uniquely designed for quick release and easy-to-remove tooling, the Star Auger granule filler ensures quick cleaning and changeover. Whether operators wish to use grams or ounces, this filling machine can do either way. You can also use it as a semi-automatic or fully-automatic filling system. For complete automation of your packaging process, integrate the Star Auger with any auxiliary machine.

An auger filler can run a wide range of products and offers better performance compared to cup fillers. This type of filling machine is called as such because it utilizes an auger screw to dispense products. If your products have any non-free-flowing characteristics or are dusty, then an auger filling is the best way to go. That said, free-flowing products also work with auger filling such as table salt or granulated sugar. It’s because products like these cannot be compressed no matter how much pressure is added and they won’t retain their shape.

[/av_textblock]

[/av_one_full]