We offer a wide array of weigh filling machines for almost every production need, accuracy requirement, space constraint and budget. Our Primo™ family of automatic weigh filling machines are designed to ensure ease of use, sanitation and serviceability. All our machines include toolless removable contact parts, stainless steel construction and leading-edge controls. These machines can weigh and fill pouches, bags, containers, cartons and cases from as little as 1 gram up to 50 pounds with fill rates from 5 to 200 dispenses per minute.

We manufacture our machines to easily integrate with our auxiliary machines including vertical form fill and seal machines, horizontal form fill and seal machines, premade pouch filling machines and container filling machines. Common weigh filling and packaging applications include candy packaging, snack food packaging, chocolate packaging, vegetable packaging, fruit packaging, cheese packaging, meat packaging, poultry packaging, pet food packaging, bakery packaging, cannabis packaging, hemp packaging, vitamin gummy packaging, pharmaceutical packaging, medicinal packaging, frozen food packaging and grain packaging.

MULTIHEAD WEIGHING

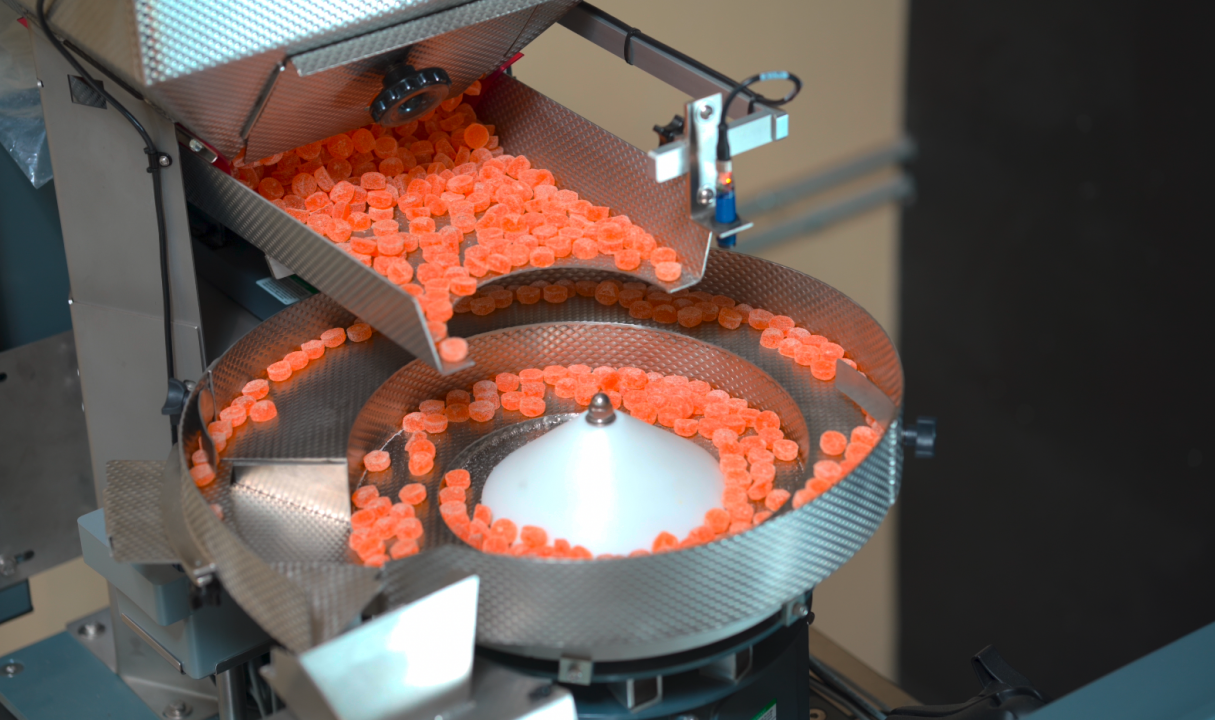

The PrimoCombi™ multi-head weigher family of automatic combination scales is commonly used when applications require the highest accuracy and overall throughput.

Offered in 10, 14, 16 and 24-head configuration, each head (or lane) includes a dedicated load cell. The process starts by filling the center of the PrimoCombi scale with bulk product which then vibrates from the center cone to the individual vibratory feeder pans. These feeder pans transport product to the weigh bucket where it is weighed and measured. Once weighed, the PrimoCombi determines which buckets equal a near-perfect match, locks them in and then triggers the buckets to dispense at the same time to an automatic packaging machine or a person manually packaging the product.

Our weighers feature standard stainless steel construction, leading-edge controls, real-time production reporting and online support.

The PrimoCombi line can be integrated with our auxiliary machines including vertical form fill and seal machines, horizontal form fill and seal machines, premade pouch filling machines and container filling machines.

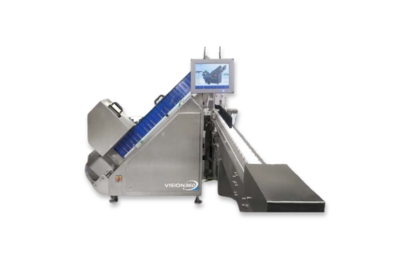

PrimoCount

Looking for the most accurate way to count your gummies, chocolates, and other wrapped products? PrimoCount stands out from the rest with its innovative dual-view scanners that ensure exceptional precision. It continuously counts your products while rejecting any that don’t meet your specifications, guaranteeing a perfect count every time.

This revision focuses on the benefits to the user and clarifies the function of the dual-view scanners. It also adds a touch of emphasis to make the product sound more appealing.

VIBRATORY NET WEIGH FILLING

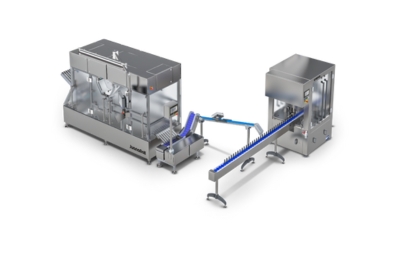

The PrimoLinear™ automatic net weigh filling machine is designed to accurately dispense and fill a wide range of products into bags, cartons, trays, boxes, jars and containers.

Designed for mid-range production needs, the PrimoLinear features a stainless steel frame, toolless removable contact parts, standardized components that reduce maintenance costs and a toolless tilting hopper that requires no changeover when running multiple applications.

Accurately weigh and fill a wide range of products including nuts, snack foods, candy, hardware, frozen foods, vegetables, fruits, meats, poultry, ingredients, spices, coffee, powders, granules and pet food.

The net weigh filling machine can be integrated with our auxiliary machines including vertical form fill and seal machines, horizontal form fill and seal machines, premade pouch filling machines and container filling machines.

CONVEYORIZED NET WEIGH FILLING

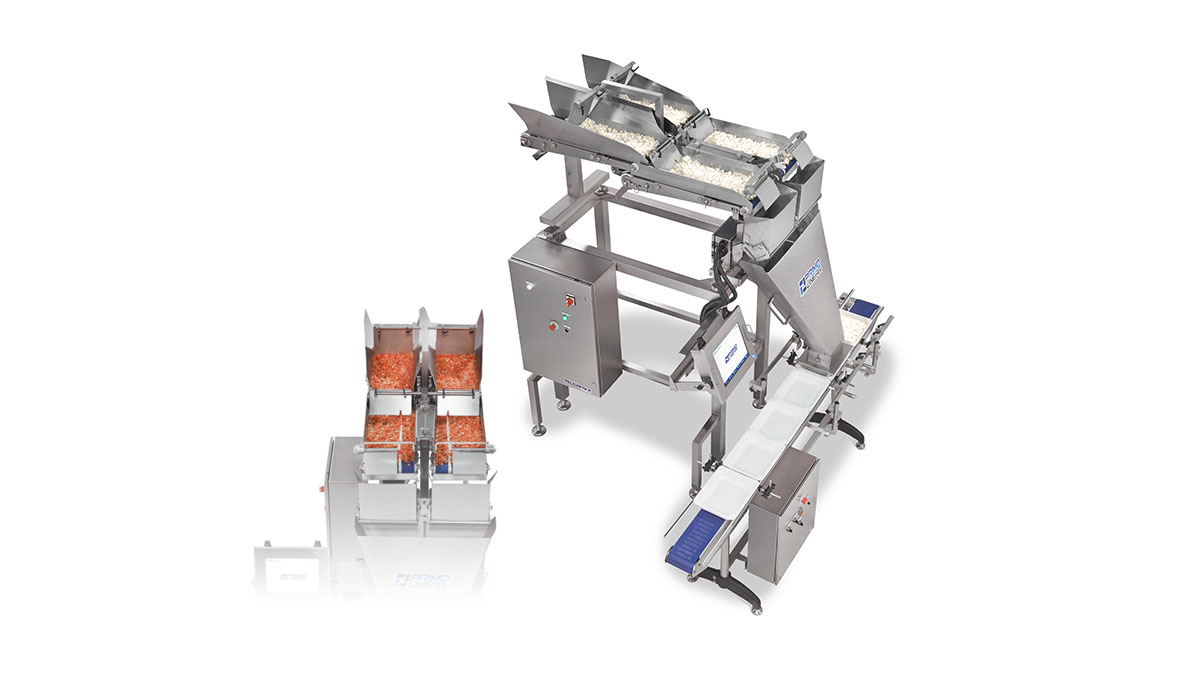

The PrimoLinear C-series is engineered for weigh filling applications where only a conveyor can successfully transfer sticky products into the weigh bucket. This series is perfect for products such as shredded, diced or sliced fresh vegetables, fruits, cheeses, meats and poultry.

Our conveyorized net weigh filling machines are manufactured in stainless steel and designed for both retail and bulk weights ranging from 5 grams to 50 pounds. Models are available in single and twin lane configurations depending on required speeds.

The C-series weigh filling machines can be integrated with auxiliary machines including vertical form fill and seal machines, premade pouch filling machines and container filling machines.

BULK WEIGH FILLING FOR LARGE FORMATS

The PrimoLinear V and T Series of bulk weigh filling machines are designed to weigh and fill both cases and totes.

The robust V-25 (vibratory) and T-25 (tote filling) models are engineered for large format filling applications from 5 to 50 pounds and are perfect for wholesale, institutional and foodservice requirements.

Common packaging applications include case or tote filling chocolates, candy, frozen foods, vegetables, fruits, baked goods, snack foods, ingredients and chemicals.

PrimoLinear V-Mini

Introducing the V-mini Weigh filler, your secret weapon for precise ingredient dispensing! This innovative system excels at handling small amounts, accurately measuring down to a single gram. With readings as detailed as 0.01 grams, you can ensure perfect consistency for even the most delicate ingredients.

Ready to conquer your orders? Contact us for pricing & ROI today.