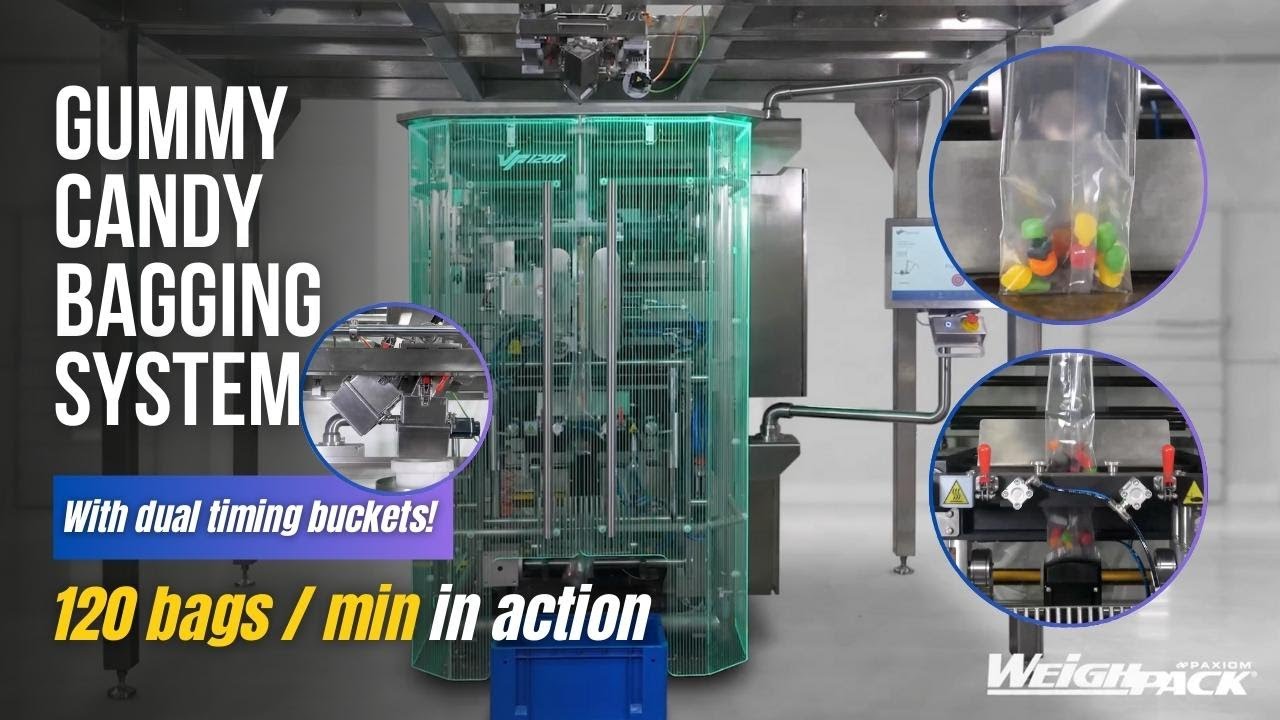

VF 1200

High Speed Continuous Motion Bagger

A vertical form fill and seal (VFFS) machine is a versatile piece of equipment used in automated production lines to create, fill, and seal packages. Here’s a breakdown of how it works:

-

Forming the Bag: The machine unwinds a roll of flat plastic film, which is then guided by a forming tube. This tube shapes the film into a pouch of the desired size.

-

Filling the Bag: Once the pouch is formed, it’s held open by a clamp. The product is then dispensed into the open pouch using a variety of filling mechanisms depending on the product characteristics. This could be by weight, auger, pump, or volumetric cup depending on the product’s consistency.

-

Sealing the Bag: After filling, the pouch is heat-sealed closed at the top. Some machines can also create a seal at the bottom of the pouch, depending on the desired style (e.g., pillow pouch vs. doy pouch).

-

Trimming and Completing the Package: After sealing, the pouch is cut from the remaining film. The finished package can then have additional features added, such as a date code, a tear notch for easy opening, or a hole punch for hanging.

Engineered for high-speed applications, this continuous motion vertical form, fill and seal machine can handle multiple package formats and produces a wide range of package sizes providing flexibility for both retail and club size packaging, up to 150 bags per minute! The vertical sealing bars are continuously in motion so the film does not need to stop to receive its vertical seal.

For mechanical rates up to 9,000 bags per hour

Videos

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

Our VF-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

-

Ideal Markets

-

Our VF-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

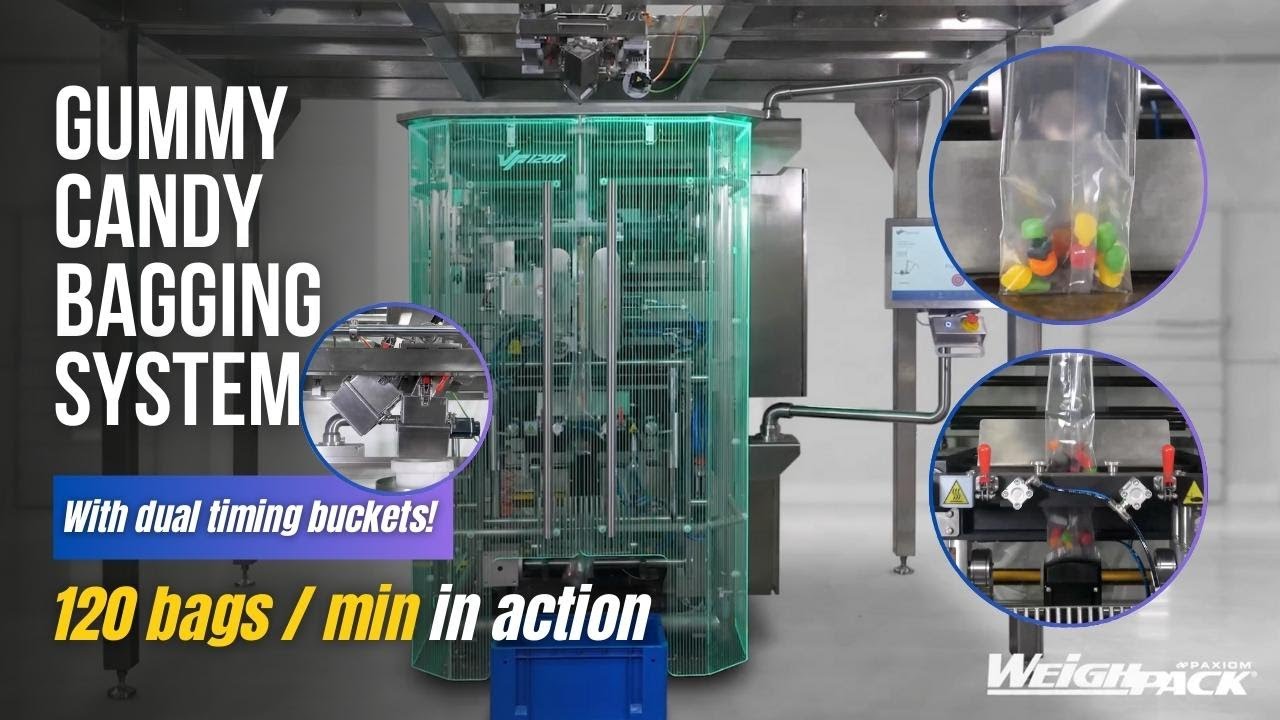

VF 1200

High Speed Continuous Motion Bagger

Videos

A vertical form fill and seal (VFFS) machine is a versatile piece of equipment used in automated production lines to create, fill, and seal packages. Here’s a breakdown of how it works:

-

Forming the Bag: The machine unwinds a roll of flat plastic film, which is then guided by a forming tube. This tube shapes the film into a pouch of the desired size.

-

Filling the Bag: Once the pouch is formed, it’s held open by a clamp. The product is then dispensed into the open pouch using a variety of filling mechanisms depending on the product characteristics. This could be by weight, auger, pump, or volumetric cup depending on the product’s consistency.

-

Sealing the Bag: After filling, the pouch is heat-sealed closed at the top. Some machines can also create a seal at the bottom of the pouch, depending on the desired style (e.g., pillow pouch vs. doy pouch).

-

Trimming and Completing the Package: After sealing, the pouch is cut from the remaining film. The finished package can then have additional features added, such as a date code, a tear notch for easy opening, or a hole punch for hanging.

Engineered for high-speed applications, this continuous motion vertical form, fill and seal machine can handle multiple package formats and produces a wide range of package sizes providing flexibility for both retail and club size packaging, up to 150 bags per minute! The vertical sealing bars are continuously in motion so the film does not need to stop to receive its vertical seal.

For mechanical rates up to 9,000 bags per hour

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

Our VF-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

-

Ideal Markets

-

Our VF-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.