Packaging Machines in Utah

As one of the country’s best outdoor states, Utah offers unique and gorgeous attractions from ski resorts to state and national parks unlike anything else in the world. What’s more, scenic drives can be done everywhere since Utah has many best sights to see. Starting with the Park City Mountain Resort, this second largest ski resort in the county has over 330 trails and an expansive 7,300-acre mountain. You can even night ski if you wish! For a splendid nature-centric trip, go to Zion National Park that features Utah’s beautiful waterfalls, Red rock cliffs, and stunning vistas amongst all other key attractions.

Then there’s also the town of Moab with its rolling petrified dunes and surrounding mountains, giving way to astounding scenery while also offering endless opportunities for outdoor adventures. And just outside Moab is the Dead Horse Point State Park. There, you can see a gooseneck in the Colorado River that’s carving through the vibrant landscape. Stretched out in the distance are 2,000-feet cliff walls and gorgeous plateaus at different levels. For museum lovers, Bean Life Science Museum is the place for you. It focuses mostly on the science behind life on Earth.

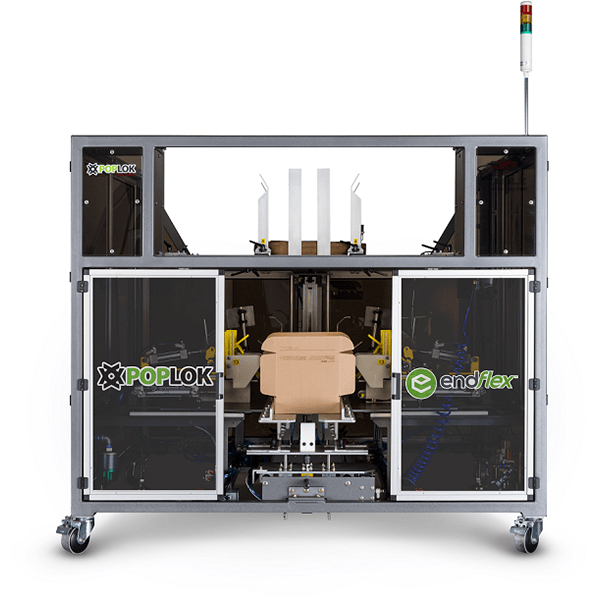

PopLok tray former for die cut trays

Understanding Carton Packing Machines

Cartoners, or cartoning machines, are packaging systems that function by erecting, closing, and filling sealed cartons. In general, a cartoner picks a flat carton, otherwise known as a blank, erect it into a square or rectangular shape, push or fill the product into the newly erected carton, then lastly, close the carton, either through a fold-over lid or the end flaps. This type of packaging machinery can be fully automatic or semi-automatic.

Cartons come in several types like open sleeves. Furthermore, they can also be categorized into multiple types like seal and overlap. Many industries use a simple fold while others prefer glue or pre-cut tabs. Also, it’s important to note that some cartoners are patented, hence, can only be applied to certain machines. Meanwhile, other patented cartoning machines can be integrated into a broad range of packaging systems. Cartons also vary in shapes such as hexagonal, triangular, octagonal, wave-shaped, and double-wall cartons, to name some.

Cartons are made mostly of carton board, which is a semi-flexible material that’s composed of layers of wood-based fiber. Cases, on the other hand, are made from corrugated boards. They are often larger and are used to contain several cartons for transit. For beverages, cartons can be added with an impervious laminated. And if the products have to be visible, then a pre-cut window over a transparent laminate is applied.

Products applicable for carton machines

Carton packaging machinery is typically used in fast-moving consumer goods, but most often on food, confectionery, coffee, tea, cosmetics, household products, tobacco, and toiletries. When considering which type of cartoning machine your business should use, it’s crucial to keep in mind factors like budget, materials used, carton size, mechanical rating, the method of transport, and your target market.

At Paxiom, our EndFlex brand specializes in creating carton forming packaging machinery. To give you an idea about our carton machines, here are two examples from our two distinct product lines: the PopLok and Boxxer

PopLok for Fold and Tuck Trays

This cartoner is designed to take a blank from the hopper one by one then pull it through its forming plows. Doing so will erect the end and side panels of the carton. While the carton erecting process happens, the minor flaps of the carton are also folded. Once the tray is at the bottom of the vertical travel, that’s when tucker bars are activated to fold and lock the roll-over flap. Finally, the finished carton goes out of the machine. Besides fold and tuck trays, our PopLok line also works on other carton configurations such as 5-tuck display, octagon 4-tuck, swing-lock 2-tuck, and tapered 2-tuck trays.

Boxxer Kartnr

Another carton forming is our Boxxer Kartnr. Unlike our PopLok series, this unique machine is a vertical cartoner that’s engineered to form, load, and close chipboard cartons. Made for compact use, this operator-friendly packaging machinery can give you 60 cartons in just one minute. The Kartnr is manufactured in two models. First is the hand load wherein the machine automatically opens and moves the carton to the fill area so a person can manually load contents to it. Once it’s loaded, the top lid can be automatically closed or left open. And then we also have the fully automatic Kartnr that’s integrated with a conveyor to automatically accumulate contents and fill them directly into the carton.