Fully Integrated Turnkey Packaging Systems

Container Filling & Handling

Complete Container Line

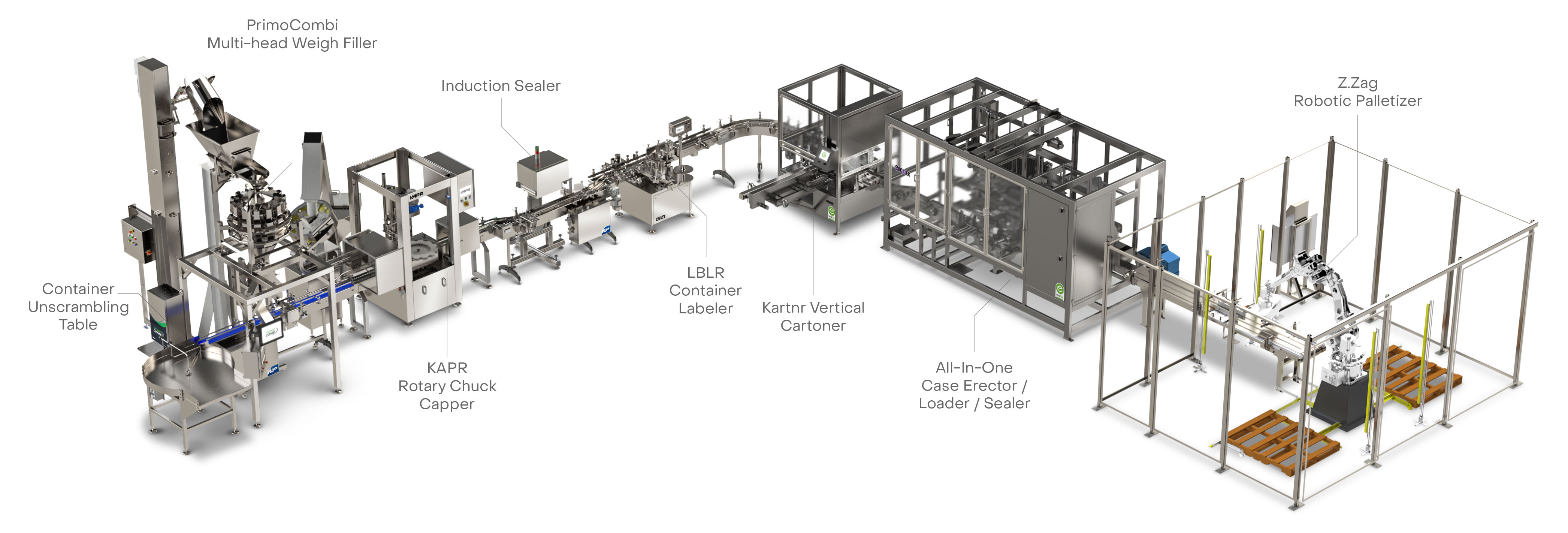

The turnkey system below was delivered to one of our clients in California to weigh and fill product into containers prior to capping, sealing and labeling. The containers are then placed into cartons ready for case packing.

We can help you automatically fill your rigid plastic, cardboard, metal or glass containers seamlessly with products such as hardware, candy, sliced fruit, nuts, salt, gummies and cannabis flower.

Videos

We’re here to help

Want to see your product run on this machine?

Bottle Packaging

Tray Forming / Case Packing / Palletizing System

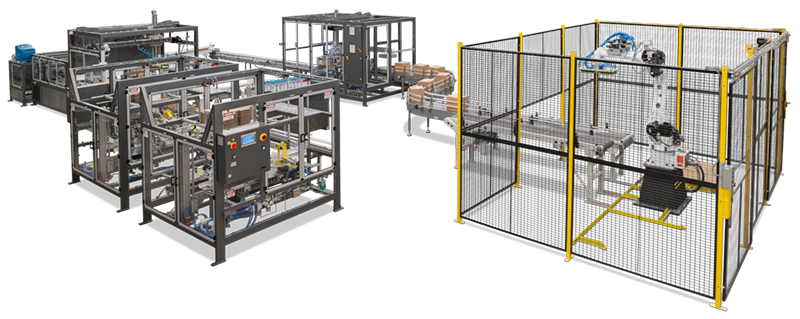

This client needed to decrease labor costs with an end-of-line solution that would work with their existing primary packaging system.

Engineered specifically to pack their bottled product, this customized system was conceived, designed and built in just 20 weeks.

We configured this system around their unique bottle shape, existing tray and case dimensions and required daily production goal. Because of its modular design, they have the flexibility to add future stations such as automated product loading and case labeling.

Let us customize a fully automated end-of-line system to meet your specific product or container size.

Videos

We’re here to help

Want to see your product run on this machine?

Bagging Systems

Pouch Filling / Drop Packing / Palletizing System

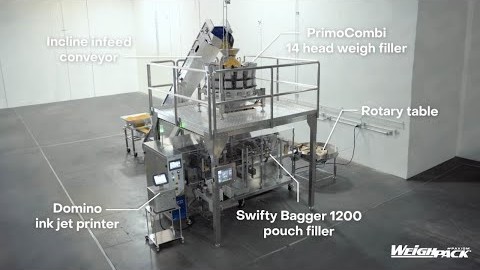

This turnkey system was specifically designed to weigh powder into bags, pack them into cases and palletize them without a single person ever touching the bags.

Our solution allowed this Utah client to repurpose their staff to more important roles and increase efficiency.

We can also customize this line to include a semiautomated case packing system for those that want to hand pack their cases prior to palletizing.

Videos

We’re here to help

Want to see your product run on this machine?

Bag-in-box Bulk Filling System

Bulk box bagging System

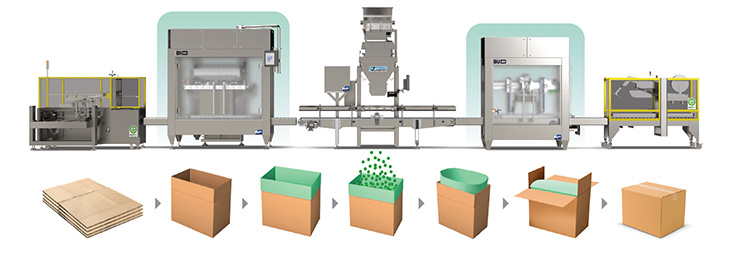

We have the solution for bagging your bulk quantities of pet food, frozen food, snacks, wrapped candy and much more with this workhorse system.

Beginning with our Boxxer case erector to form the case, our BI 600 bag inserter then dispenses film on a roll, cuts, seals and inserts the bag into the case. Once the product is weighed and filled, using a V25 bulk weigh filler in this case, the case then passes to the BU 600 bag uncuffer. The bag is then uncuffed from the case and folded over the product prior to passing to our EZ Tape case sealer. Bag sealing and vacuum assemblies are also available.

This system can be easily matched up with our Z.Zag robotic palletizer to fully automate your bulk bagging line.

Videos

We’re here to help

Want to see your product run on this machine?

Complete Pre Roll Automation

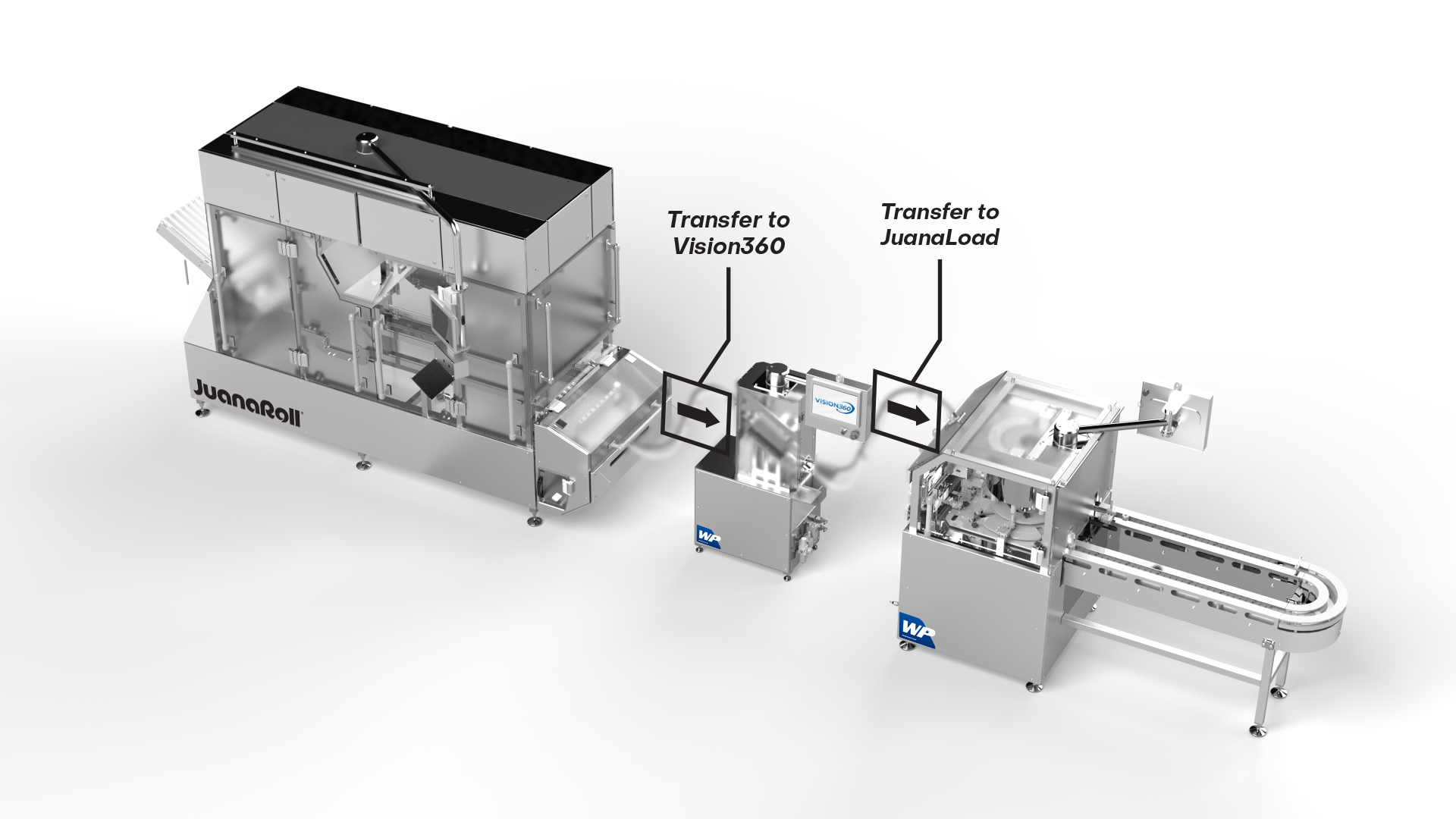

CANNABIS PRE ROLL PRODUCTION, VISION INSPECTION, CHECK WEIGHING & TUBE/TRAY LOADING SYSTEM

This customizable pre-roll loading system seamlessly integrates with the JuanaRoll pre-roll machine, automatically conveying pre-rolls for loading into tubes, capping, and sealing. Alternatively, it can be installed as a standalone unit to enhance your manual pre-roll delivery process. This system can be paired with our tube labeling and capping machines to produce a finished, retail-ready product.

Operating options include:

- A fully integrated system from JuanaRoll.

- Integration with your existing pre-roll machine.

- Manual loading from your KnockBox directly into the system.

- Conveyor feeding from your pre-roll machine, with our robotic system picking and placing pre-rolls into the desired package.

Videos

We’re here to help

Want to see your product run on this machine?

Container Filling & Handling

COMPLETE CONTAINER LINE

The turnkey system below was delivered to one of our clients in California to weigh and fill product into containers prior to capping, sealing and labeling. The containers are then placed into cartons ready for case packing.

We can help you automatically fill your rigid plastic, cardboard, metal or glass containers seamlessly with products such as hardware, candy, sliced fruit, nuts, salt, gummies and cannabis flower.

Bottle Packaging

Tray Forming / Case Packing / Palletizing System

This client needed to decrease labor costs with an end-of-line solution that would work with their existing primary packaging system.

Engineered specifically to pack their bottled product, this customized system was conceived, designed and built in just 20 weeks.

We configured this system around their unique bottle shape, existing tray and case dimensions and required daily production goal. Because of its modular design, they have the flexibility to add future stations such as automated product loading and case labeling.

Let us customize a fully automated end-of-line system to meet your specific product or container size.

Bagging Systems

Pouch Filling / Drop Packing / Palletizing System

This turnkey system was specifically designed to weigh powder into bags, pack them into cases and palletize them without a single person ever touching the bags.

Our solution allowed this Utah client to repurpose their staff to more important roles and increase efficiency.

We can also customize this line to include a semiautomated case packing system for those that want to hand pack their cases prior to palletizing.

Bag-in-box Bulk Filling System

Bulk box bagging System

We have the solution for bagging your bulk quantities of pet food, frozen food, snacks, wrapped candy and much more with this workhorse system.

Beginning with our Boxxer case erector to form the case, our BI 600 bag inserter then dispenses film on a roll, cuts, seals and inserts the bag into the case. Once the product is weighed and filled, using a V25 bulk weigh filler in this case, the case then passes to the BU 600 bag uncuffer. The bag is then uncuffed from the case and folded over the product prior to passing to our EZ Tape case sealer. Bag sealing and vacuum assemblies are also available.

This system can be easily matched up with our Z.Zag robotic palletizer to fully automate your bulk bagging line.

Pre Roll Tube Loading

CANNABIS PRE ROLL FILLING AND TUBE LOADING SYSTEM

This customizable pre-roll loading system seamlessly integrates with the JuanaRoll pre-roll machine, automatically conveying pre-rolls for loading into tubes, capping, and sealing. Alternatively, it can be installed as a standalone unit to enhance your manual pre-roll delivery process. This system can be paired with our tube labeling and capping machines to produce a finished, retail-ready product.

Operating options include:

- A fully integrated system from JuanaRoll.

- Integration with your existing pre-roll machine.

- Manual loading from your KnockBox directly into the system.

- Conveyor feeding from your pre-roll machine, with our robotic system picking and placing pre-rolls into the desired package.