Packaging Machine Systems in Texas

As the second-largest U.S. state, it’s no surprise that Texas is loaded with countless opportunities to have fun. Moreover, its diverse culture opens up a huge way for other unique attractions to flourish. In the middle of Central Texas is an oasis called SeaWorld San Antonio, one of the largest marine-life theme parks in the world. The place offers a water park, nautical roller coasters, and a huge menagerie of sea creatures. Situated somewhere in the middle of a vast beaten path in Valentine is Prada Marfa, an art installation that was built to resemble one of Prada’s house boutiques.

On a huge bend in the Rio Grande River lies the Big Bend National Park, a uniquely stunning scenery where you can see canyons, mountains, and the river flowing along the border that separates the country from Mexico. The park has a diverse range of things to do outdoor enthusiasts will surely enjoy exploring. It’s also home to more than 400 bird species, which makes birdwatching a popular pastime in the area. Want a magical experience? Camp out at Enchanted Rock. Legend has it that the place gives anyone who stays overnight magical powers. But legend or not, this enormous pink granite dome is a perfect place to stargaze, hike, camp, rock climb, and many more.

The importance of vibratory fillers

Fillers are a type of packaging machines that are mainly used for foods and beverages. Depending on the product, these are used to fill a pouch, jar, bottle, or other container types. The packaging industry has grown so much over the years. As such, several types of filling machines have been invented and are now commonly used in the industry. One of these is the vibratory weigh-fillers. Vibratory weigh filling machines are designed to offer the perfect blend of products with speed, accuracy, and versatility in mind.

These packaging machines work with a broad line of linear feeders. They are also equipped with a weighing hopper that can handle specific needs and weight requirements. Overall, vibratory filler machines are crucial for manufacturers and businesses that produce a variety of dry and small products like trail mix. That’s because products like these require a certain mechanism that will sort through it all efficiently and quickly.

How vibratory fillers can help you

Vibratory filler machines can be semi-automatic or fully automatic, depending on your preferred model. In general, they provide simple operation and installation. Moreover, they’re known for their energy-saving benefits and are offered in multiple dimensions, sizes, and capacities to match the unique needs and preferences of businesses. They can also be manufactured as a single-head filler or a multi-head filler, depending on the required accuracy.

Vibratory filling packaging machines provide high accuracy rates when sorting products, even irregularly-shaped items. Additionally, this type of filling machine is ideal for meticulous applications that require careful handling and high precision, as opposed to other filler machines that are geared more for bulk packaging or liquid filtering.

PrimoLinear series of Vibratory Fillers

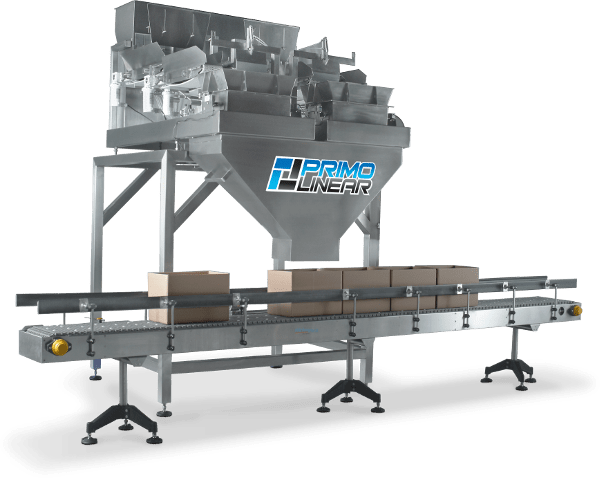

At Paxiom, we offer a broad range of automatic weigh-filling machines that are designed to fill products into different container types. Coming from the PrimoLinear product line, these vibratory fillers are available in several models, namely:

V-5

Can be upgraded to a modular design, our V-5 vibratory filler lets business owners expand their production line by adding new lanes to the machine. This filler also has a quick-access drawer at the back of the V-5 to allow the fastest servicing possible. With its 360 Operating Software, the entire PrimoLinear series has significantly streamlined the way businesses manage their production, allowing operators to take control over the machine through its PC controls.

V-25

This automatic vibratory filler offers a clean and uncluttered design, in addition to its stainless steel construction. If you have any existing auxiliary machine, you can also integrate the V-25 with it as it features an independent floor frame and modular design. Designed to fill and dispense free-flowing products, this packaging machine has mounted vibratory pans to let operators have complete control over the filler. Other features include a two-speed control, ability to read in one gram increments, flow controls, and off-center load cell.

V-Mini

Built with a pneumatic gate, the V-mini guarantees overall accuracy by ensuring that no additional product goes to the bulk pan. It also features a mechanical and clean design to deter bacteria buildup. Thanks to its open-frame design and stainless steel construction, wash-down time is greatly reduced. This vibratory filler offers reporting tools, free online support, and advanced PC controls.