Swifty Bagger Side Load

for horizontal loading

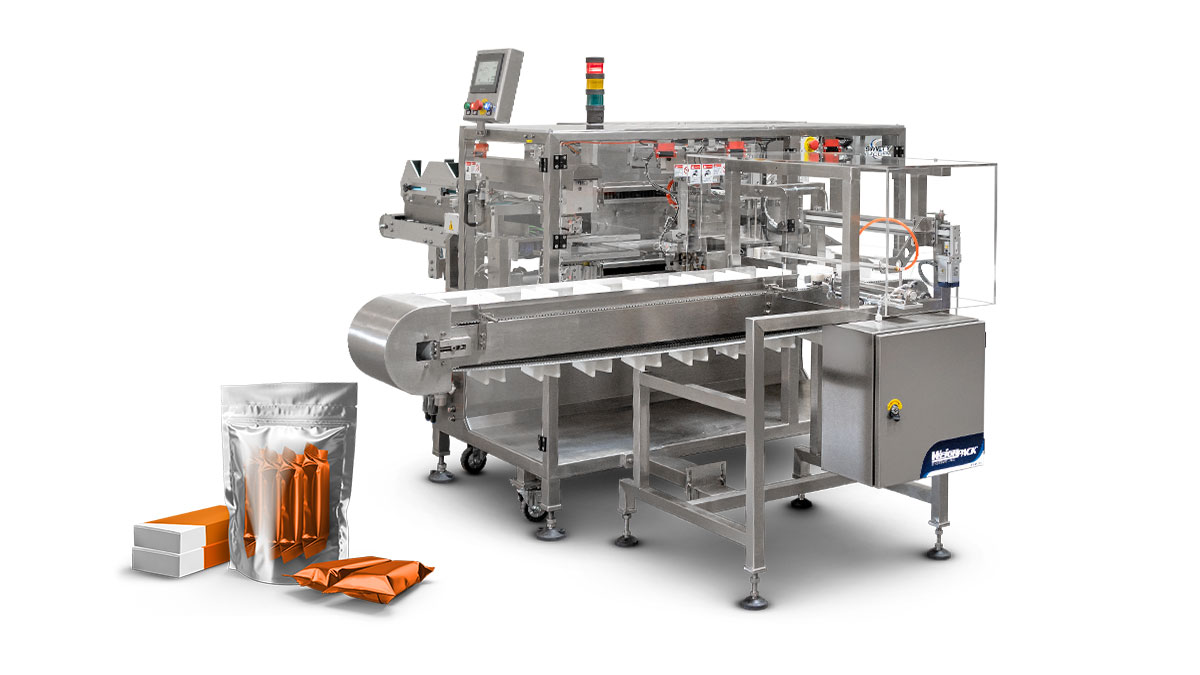

Our unique Swifty Bagger Side Load automatic bagging machine is engineered to load and fill pre-made pouches horizontally.

Loading product horizontally creates a distinct appearance within the pouch that works well for marketing pre-packaged snack foods and supplements as well as pet chews and is perfect for products that need to be oriented in a specific direction such as medical devices or printed materials.

Constructed with stainless steel, this machine features a quick bag loading station with vacuum mechanism, a color touch screen and a no bag-no fill sensor. The straight-flow design allows the operator to see the entire filling process from the front side of the machine.

Videos

Features

- Straight-flow design makes accessibility of parts and allows the operator to see the entire filling process from the front

- Easy to clean by simply opening the front clear transparent doors of the machine and access all bag filling areas.

- Omron PLC

- Temperature controller

- Color touch screen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Side Load is suited for all industries as your go to horizontal pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Straight-flow design makes accessibility of parts and allows the operator to see the entire filling process from the front

- Easy to clean by simply opening the front clear transparent doors of the machine and access all bag filling areas.

- Omron PLC

- Temperature controller

- Color touch screen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Swifty Bagger Side Load is suited for all industries as your go to horizontal pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

Swifty Bagger Side Load

for horizontal loading

Our unique Swifty Bagger Side Load automatic bagging machine is engineered to load and fill pre-made pouches horizontally.

Loading product horizontally creates a distinct appearance within the pouch that works well for marketing pre-packaged snack foods and supplements as well as pet chews and is perfect for products that need to be oriented in a specific direction such as medical devices or printed materials.

Constructed with stainless steel, this machine features a quick bag loading station with vacuum mechanism, a color touch screen and a no bag-no fill sensor. The straight-flow design allows the operator to see the entire filling process from the front side of the machine.

Features

- Straight-flow design makes accessibility of parts and allows the operator to see the entire filling process from the front

- Easy to clean by simply opening the front clear transparent doors of the machine and access all bag filling areas.

- Omron PLC

- Temperature controller

- Color touch screen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Side Load is suited for all industries as your go to horizontal pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Straight-flow design makes accessibility of parts and allows the operator to see the entire filling process from the front

- Easy to clean by simply opening the front clear transparent doors of the machine and access all bag filling areas.

- Omron PLC

- Temperature controller

- Color touch screen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Swifty Bagger Side Load is suited for all industries as your go to horizontal pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.