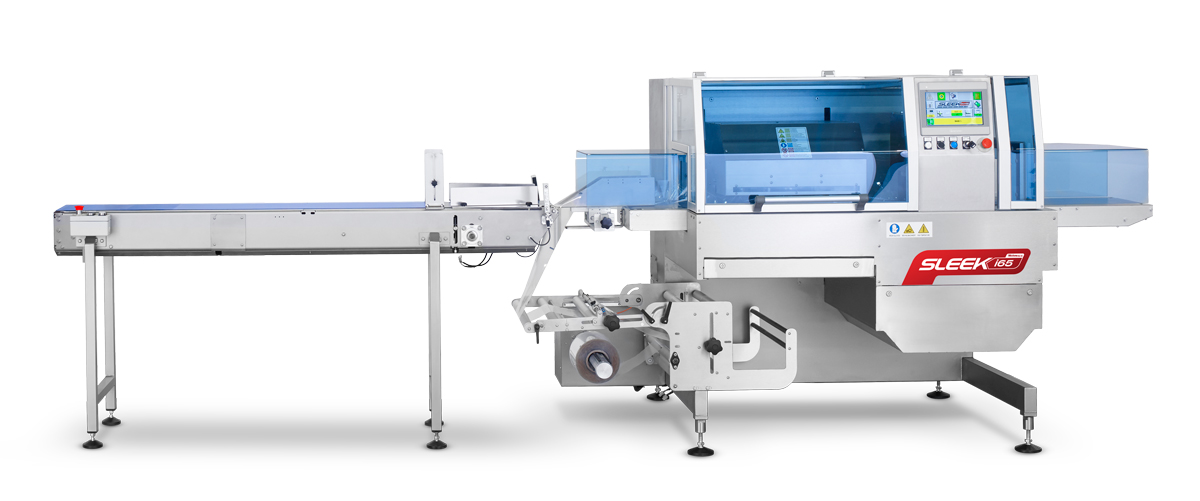

SLEEK I-65

Inverted Flow Wrapping

The high-performance SleekWrapper Inverted horizontal wrapping machine is designed with reliability, simplicity and serviceability in mind. Built for a 24/7 environment, this machine will produce up to 60 packages per minute with a maximum web width of 25.5 inches or 650mm.

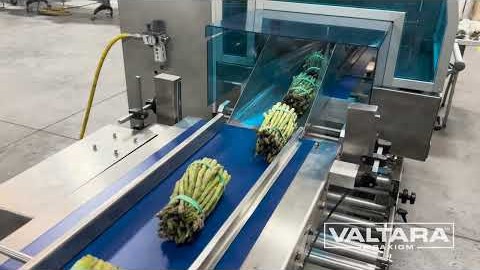

It is ideal for soft or sticky products, multipacks and other products that are difficult to push with the typical lug chain design found on conventional bottom seal flow wrappers. The film is fed from below the product and hard-to-handle products are securely carried on top of the packaging film from the former through to the cutting head.

The Sleek Inverted features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Five servo-driven motors assure precise positioning with smooth acceleration and deceleration.

This machine comes standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Videos

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

Our Sleek I-65 is suited for all industries as your go to inverted flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

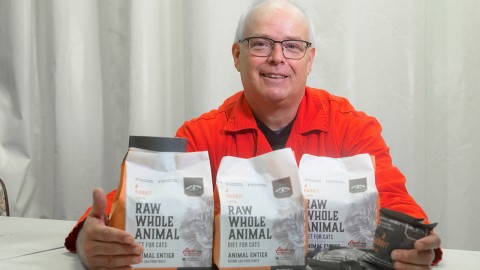

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Sleek I-65 is suited for all industries as your go to inverted flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

SLEEK I-65

Inverted Flow Wrapping

Videos

The high-performance SleekWrapper Inverted horizontal wrapping machine is designed with reliability, simplicity and serviceability in mind. Built for a 24/7 environment, this machine will produce up to 60 packages per minute with a maximum web width of 25.5 inches or 650mm.

It is ideal for soft or sticky products, multipacks and other products that are difficult to push with the typical lug chain design found on conventional bottom seal flow wrappers. The film is fed from below the product and hard-to-handle products are securely carried on top of the packaging film from the former through to the cutting head.

The Sleek Inverted features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Five servo-driven motors assure precise positioning with smooth acceleration and deceleration.

This machine comes standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

Our Sleek I-65 is suited for all industries as your go to inverted flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Sleek I-65 is suited for all industries as your go to inverted flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.