Boxxer Side Load

Case Forming and Side Loading Machine

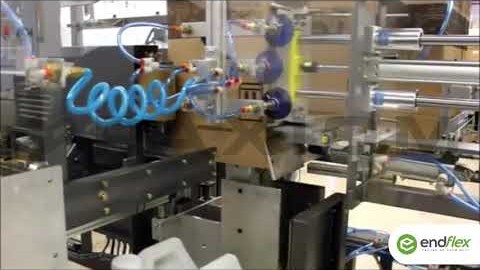

Introducing our versatile automatic side load case packing machines. Designed to efficiently load cartons, bottles, and containers into corrugated cases, these machines are ideal for high-speed applications and delicate product handling.

How it works:

- Automatic case forming: Corrugated cases are shaped and formed automatically.

- Product conveyance: Incoming products (containers, jugs, bottles, cartons, boxes, etc.) are conveyed to a staging area.

- Product stacking: Products are stacked and staged according to your desired pack pattern.

- Gentle loading: Cases are loaded from the bottom, ensuring delicate and careful product handling.

- Case sealing: Bottom and top flaps of the corrugated case are folded and sealed with either glue or tape.

- Ready to ship: The finished, case-packed product is ready for shipment to your customers.

Perfect for products like:

- Delicate baked goods

- Heavy cartons

- Containers with liquids

- And more!

Videos

Features

- Product staging and loading area

- Servo loading mechanism

- Case erector

- Quick size change-over

- Heavy duty, welded tubular steel frame

- Venturi vacuum technology

- Omron PLC

- Color touch screen user interface allowing adjustment and full access to all functions & timing of machine

- 2” or 3” wide tape head or Nordson ProBlue glue system

- Low product and no product detectors on infeed

- Interlocked safety gates or doors

- Auto-idler

- Light stack and audible low hopper alarm

- Utility blow out air line with nozzle

- All electric controls

- STEEL-IT silver grey paint with all moving parts painted bright yellow

- 24 VDC control voltage

- On-line detailed operation manual accessible through HMI

- Product staging and loading area

*Rates subject to package style, type and size

Our Side Load Case Packer is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Product staging and loading area

- Servo loading mechanism

- Case erector

- Quick size change-over

- Heavy duty, welded tubular steel frame

- Venturi vacuum technology

- Omron PLC

- Color touch screen user interface allowing adjustment and full access to all functions & timing of machine

- 2” or 3” wide tape head or Nordson ProBlue glue system

- Low product and no product detectors on infeed

- Interlocked safety gates or doors

- Auto-idler

- Light stack and audible low hopper alarm

- Utility blow out air line with nozzle

- All electric controls

- STEEL-IT silver grey paint with all moving parts painted bright yellow

- 24 VDC control voltage

- On-line detailed operation manual accessible through HMI

- Product staging and loading area

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Side Load Case Packer is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

Boxxer Side Load

Case Forming and Side Loading Machine

Videos

Introducing our versatile automatic side load case packing machines. Designed to efficiently load cartons, bottles, and containers into corrugated cases, these machines are ideal for high-speed applications and delicate product handling.

How it works:

- Automatic case forming: Corrugated cases are shaped and formed automatically.

- Product conveyance: Incoming products (containers, jugs, bottles, cartons, boxes, etc.) are conveyed to a staging area.

- Product stacking: Products are stacked and staged according to your desired pack pattern.

- Gentle loading: Cases are loaded from the bottom, ensuring delicate and careful product handling.

- Case sealing: Bottom and top flaps of the corrugated case are folded and sealed with either glue or tape.

- Ready to ship: The finished, case-packed product is ready for shipment to your customers.

Perfect for products like:

- Delicate baked goods

- Heavy cartons

- Containers with liquids

- And more!

Features

- Product staging and loading area

- Servo loading mechanism

- Case erector

- Quick size change-over

- Heavy duty, welded tubular steel frame

- Venturi vacuum technology

- Omron PLC

- Color touch screen user interface allowing adjustment and full access to all functions & timing of machine

- 2” or 3” wide tape head or Nordson ProBlue glue system

- Low product and no product detectors on infeed

- Interlocked safety gates or doors

- Auto-idler

- Light stack and audible low hopper alarm

- Utility blow out air line with nozzle

- All electric controls

- STEEL-IT silver grey paint with all moving parts painted bright yellow

- 24 VDC control voltage

- On-line detailed operation manual accessible through HMI

- Product staging and loading area

*Rates subject to package style, type and size

Our Side Load Case Packer is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Product staging and loading area

- Servo loading mechanism

- Case erector

- Quick size change-over

- Heavy duty, welded tubular steel frame

- Venturi vacuum technology

- Omron PLC

- Color touch screen user interface allowing adjustment and full access to all functions & timing of machine

- 2” or 3” wide tape head or Nordson ProBlue glue system

- Low product and no product detectors on infeed

- Interlocked safety gates or doors

- Auto-idler

- Light stack and audible low hopper alarm

- Utility blow out air line with nozzle

- All electric controls

- STEEL-IT silver grey paint with all moving parts painted bright yellow

- 24 VDC control voltage

- On-line detailed operation manual accessible through HMI

- Product staging and loading area

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Side Load Case Packer is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.