Prana Organic, Canada

“THANKS TO PAXIOM, I’M NOT

AFRAID OF ROBOTICS ANYMORE.”

Prana Organic, Canada

“THANKS TO PAXIOM,

I’M NOT AFRAID OF

ROBOTICS ANYMORE.”

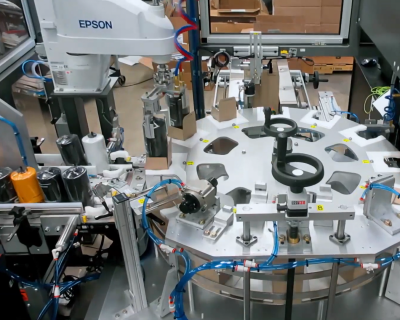

Robotic Packaging Machines: Compact & Affordable

Manufactured at our state-of-the-art facilities in Miami and Italy, our robotic cells are designed for seamless integration and user-friendly operation, providing both affordability and high performance.

Why Choose Robotic Packaging Automation?

Businesses across industries are increasingly turning to robotic automation for their packaging needs due to its transformative benefits:

- Efficiency & Productivity: Robotic systems quickly handle repetitive tasks, reducing packaging time and increasing output to meet high demand without extra labor.

- Accuracy & Consistency: Ensures precise, error-free packaging, minimizing waste and maintaining high quality.

- Cost Savings: Lowers labor and operational costs, while reducing material waste and damage.

- Adaptability & Customization: Easily reconfigured for various packaging formats and product types, allowing scalability.

- Improved Workplace Safety: Robots take on hazardous tasks, reducing workplace injuries and freeing employees for complex roles.

Ready to transform your packaging process? Contact Paxiom today to explore our robotic automation solutions and discover how we can help you boost productivity, reduce costs, and enhance safety in your operations.

Compact & Affordable Robotic Packaging Automation

Manufactured at our Miami & Italian facilities, our robotic cells are easy to use and integrate

Your Step Into The

Future of Production!

Xperience packaging at

a whole new pace

- Efficiency, speed & precision in every pick & place

- Liberate your staff from repetitive and dangerous tasks

- Take advantage of the benefits offered by Industry 4.0

Our Solutions

- ROBOTIC CASE/TRAY PACKING

- CARTON LOADING & ORIENTING

- PALLETIZING & DEPALLETIZING

- ROBOTIC PRODUCT LOADING

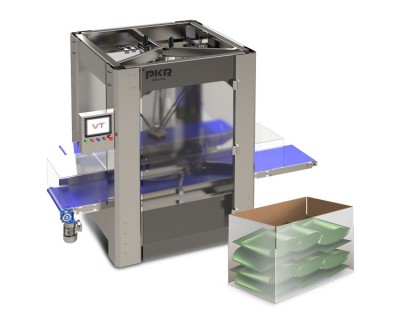

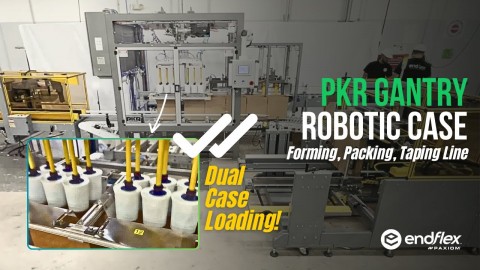

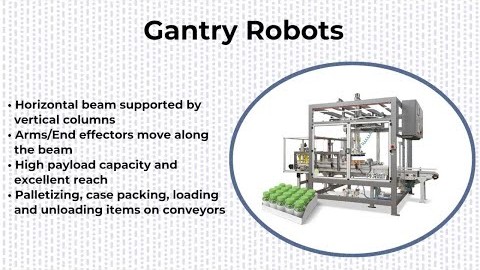

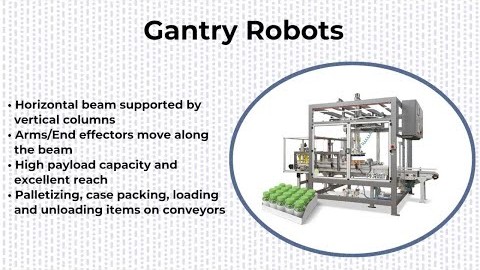

PKR GANTRY

For Cans, Jars, Cartons & Trays

The PKR Gantry Robot is a versatile pick-and-place system designed to automate the top-loading of jars, cans, cartons, clam shells, and other products into cases or trays.

Key Features

- X, Y, Z-axis functionality enables precise movement across three axes, ensuring accurate product placement.

- Gentle product handling utilizes vacuum or mechanical pickup methods to maintain product integrity during loading.

- Compact footprint is designed to fit seamlessly into existing packaging lines, optimizing space utilization.

- Versatile product compatibility handles various items such as jars, cans, bottles, and clamshells.

- Integration capability allows it to be combined with any case or tray former to streamline the packaging process and reduce labor costs.

- Quick changeovers with quick-release change parts enable fast product transitions, enhancing operational efficiency.

- User-friendly interface equipped with a color touch screen for easy operation and monitoring.

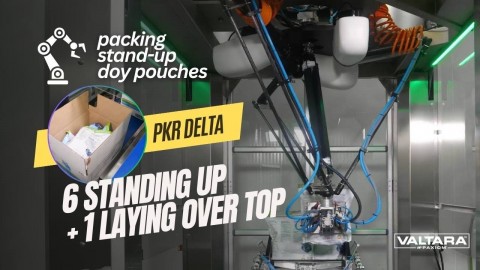

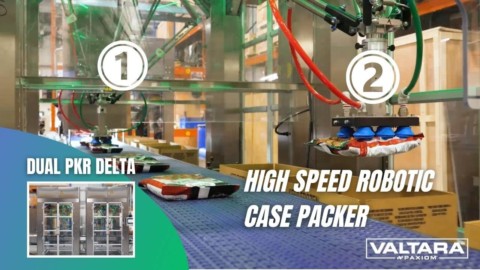

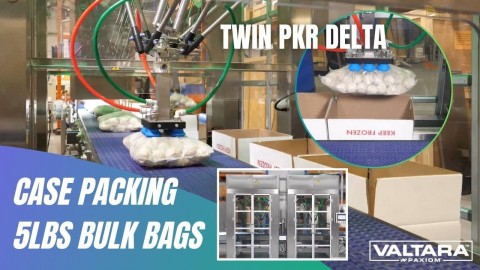

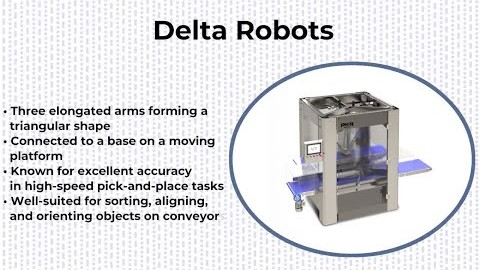

PKR DELTA

For Bags

The PKR Delta is a high-speed, precise robotic solution designed to load flexible packages like stand-up pouches, lay-flat bags, and clam shells or top-sealed cups into cases or trays.

Key Features

- Flexible packaging configurations handle stand-up pouches, lay-flat bags, and vertical form, fill, seal pouches (up to 85 per minute), tailored for various arrangements.

- Versatile applications allow it to pack bakery clamshells into trays and load top-sealed 2 or 4 cups into cartons.

- Optimized for snack packaging with proven reliability for premium snack packaging, providing precise, high-speed performance adaptable to diverse needs.

- High-resolution vision system ensures accurate picking and placing of retail bags, enhancing precision in packaging operations.

- Stainless steel construction offers durability and hygiene, making it ideal for retail packaging environments.

PKR 6-AXIS ROBOT

With Articulated Arm

The PKR 6-Axis Robot is a modular pick-and-place system designed to automate the top-loading of products into cases or trays, especially in facilities with limited height.

Key Features

- Yaskawa GP12 articulated robot provides six-axis movement for precise and flexible product handling.

- Compact design fits seamlessly into existing packaging lines, optimizing space utilization.

- Gentle product handling utilizes vacuum or mechanical pickup methods to maintain product integrity during loading.

- Versatile product compatibility allows it to handle various items such as cartons, cans, bottles, and bags in single or multiple layers.

- Integration capability enables it to be combined with any case or tray former to streamline the packaging process and reduce labor costs.

- Quick changeovers feature quick-release change parts for fast product transitions, enhancing operational efficiency.

- User-friendly interface is equipped with a color touch screen for easy operation and monitoring.

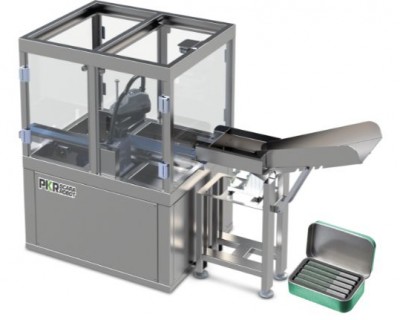

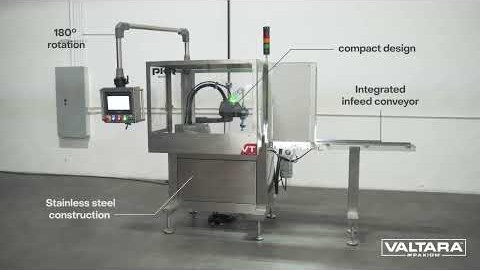

PKR SCARA

For Pre-Roll Tray Loading

The PKR Scara is a robotic pick-and-place system engineered for rapid and precise product feeding and sorting.

Key Features

- Compact design optimizes floor space with a sleek, space-saving structure, ideal for tight production environments.

- 180° rotation capability offers full 180-degree rotation, allowing the robot to reach and handle items from various angles, enhancing operational flexibility.

- User-friendly interface is equipped with a large color touch screen, providing intuitive control and easy programming for seamless operation.

- Seamless integration allows it to be incorporated into various packaging processes, including flow wrapping, to create customized automation solutions.

- Enhanced efficiency automates repetitive tasks, reducing manual labor and increasing throughput, thereby improving overall production efficiency.

Robotic Case & Tray Packing Automation Solutions

Automate the packing process with precision and speed using Paxiom's robotic case and tray packing systems. Designed to handle various product sizes and packaging formats, these systems increase efficiency while reducing the need for manual labor, ensuring consistent and reliable product placement for a wide range of industries.

PKR DELTA

For Carton Loading

The PKR Delta is a high-speed, precise robotic solution designed to load flexible packages like stand-up pouches and lay-flat bags into cases or trays.

Key Features

- Seamlessly integrates with the Kartnr V cartoner to enable the streamlined loading of a variety of products into cartons.

- Serves as the primary handling component in the robotic carton loading system, picking and placing products into the cartons prepared by the Kartnr V machine.

- Streamlines and optimizes product loading in packaging processes by efficiently handling a wide range of product types, including those that are typically difficult to manage, such as tall or oddly shaped items, directly into cartons formed by the Kartnr V machine.

- Stainless steel construction offers durability and hygiene, making it ideal for retail packaging environments.

- Suitable for use in various industries, including fruit, snack food, vegetable, and nutraceutical industries.

KARTNR

With Robotic Loading

The Kartnr V is a vertical cartoning machine engineered to automatically form, load, and close small to medium-sized chipboard cartons.

Key Features

- Versatile carton handling accommodates various carton styles, including tucked, pop-up auto-lock, and glued cartons, making it suitable for diverse packaging needs.

- Quick size changeover is designed for rapid adjustments, allowing seamless transitions between different carton sizes and styles to enhance production efficiency.

- User-friendly interface is equipped with a color touch screen and Omron PLC for intuitive operation and easy access to all machine functions and timing adjustments.

- Smooth carton indexing features a rotary star wheel mechanism that ensures precise and gentle handling of cartons throughout the packaging process.

- Safety features incorporate interlocked safety doors and advanced safety circuits to protect operators and maintain a secure working environment.

Automated Carton Loading & Product Orienting Systems

Streamline carton loading with precision and consistency using Paxiom’s automated systems, designed to handle various product orientations. These systems ensure that each product is accurately positioned within cartons, enhancing efficiency and reducing manual labor, making them ideal for businesses seeking consistent and reliable packaging solutions.

Z.ZAG PALLETIZER

For Palletizing & Depalletizing

The Z.Zag Robotic Palletizer/Depalletizer is a versatile automation solution designed to enhance end-of-line packaging processes.

Key Features

- High-performance 5-axis robot is equipped to handle payloads up to 80 kg, ensuring efficient and precise palletizing and depalletizing operations.

- Versatile application is ideal for case palletizing, bag palletizing, order picking, and various logistical tasks, making it suitable for end-of-line or distribution center automation.

- Enhanced safety and efficiency automates pallet loading and unloading processes, reducing the risk of injury from manual handling and increasing operational efficiency.

- Customizable solutions offer tailored configurations to meet specific palletizing needs, accommodating cases, trays, bags, and containers.

- Compact footprint is designed to fit seamlessly into existing production lines without requiring extensive space, optimizing facility layout.

Z.ZAG COBOT

Collaborative Robot

The Z.Zag Cobot is a collaborative robot designed to work alongside human operators, enhancing efficiency and safety in various industrial applications.

Key Features

- Human collaboration is engineered to operate safely alongside human workers, facilitating a collaborative work environment.

- Advanced safety features include sensors and safety mechanisms that detect human presence, allowing the cobot to adjust its movements to prevent injuries.

- Space-efficient design has a compact footprint that enables integration into existing workspaces without significant modifications, optimizing floor space.

- Versatile functionality allows it to perform a wide range of tasks, including palletizing, depalletizing, and other logistical operations.

- User-friendly interface with intuitive controls makes programming and operation straightforward, reducing the need for extensive training.

- Enhanced productivity is achieved by automating repetitive tasks, increasing throughput and operational efficiency.

Palletizing & Depalletizing Automation for Packaging Efficiency

Enhance workflow with Paxiom’s automated palletizing and depalletizing solutions, designed to handle products safely and efficiently. These systems streamline the stacking and unstacking process, reducing labor costs and increasing operational speed, making them ideal for businesses aiming to boost productivity and optimize space in their facilities.

PKR SCARA

Robotic Loading for Flow Wrapping

The PKR Scara is a robotic pick-and-place system engineered for rapid and precise product feeding and sorting.

Key Features

- ompact design optimizes floor space with a sleek, space-saving structure, ideal for tight production environments.

- 180° rotation capability offers full 180-degree rotation, allowing the robot to reach and handle items from various angles, enhancing operational flexibility.

- User-friendly interface is equipped with a large color touch screen, providing intuitive control and easy programming for seamless operation.

- Seamless integration allows it to be incorporated into various packaging processes, including flow wrapping, to create customized automation solutions.

- Enhanced efficiency automates repetitive tasks, reducing manual labor and increasing throughput, thereby improving overall production efficiency.

Robotic Product Loading Solutions for Streamlined Packaging

Optimize efficiency with Paxiom’s robotic product loading systems, engineered to automate the precise placement of products into containers. Designed for accuracy and high throughput, these systems reduce handling errors and labor costs, making them ideal for businesses looking to enhance their packaging line’s productivity and consistency.

MEET OUR

PACKAGING ROBOTS

ROBOTIC CASE & TRAY PACKING

PKR GANTRY

For Cans, Jars, Cartons & Trays

PKR DELTA

For Bags

CARTON LOADING & ORIENTING

PALLETIZING & DEPALLETIZING

Z.ZAG PALLETIZER

For Palletizing & Depalletizing

ROBOTIC PRODUCT LOADING

Industries Served

Paxiom’s robotic packaging systems are designed to meet the diverse needs of various industries, delivering precision, efficiency, and adaptability. Here’s how Paxiom’s solutions benefit key sectors:

- Food & Beverage: Automated systems ensure high-speed, safe handling of products to meet the strict hygiene standards and efficiency demands of food and beverage packaging.

- Pharmaceuticals: Paxiom’s solutions offer precise, controlled handling essential for pharmaceutical packaging, maintaining product integrity and compliance with industry regulations.

- Consumer Goods: From personal care items to household products, Paxiom’s versatile robotic systems provide efficient, reliable packaging that accommodates varied product shapes and sizes.

- Cosmetics: Cosmetic packaging benefits from Paxiom’s gentle product handling and customizable options, ideal for delicate and uniquely shaped products.

- E-commerce/Distribution: For fast-moving e-commerce and distribution centers, Paxiom’s automated systems streamline order fulfillment, enhancing productivity and accuracy in packing and palletizing.

Ready to Supercharge Your Production? Contact us for pricing & ROI today.