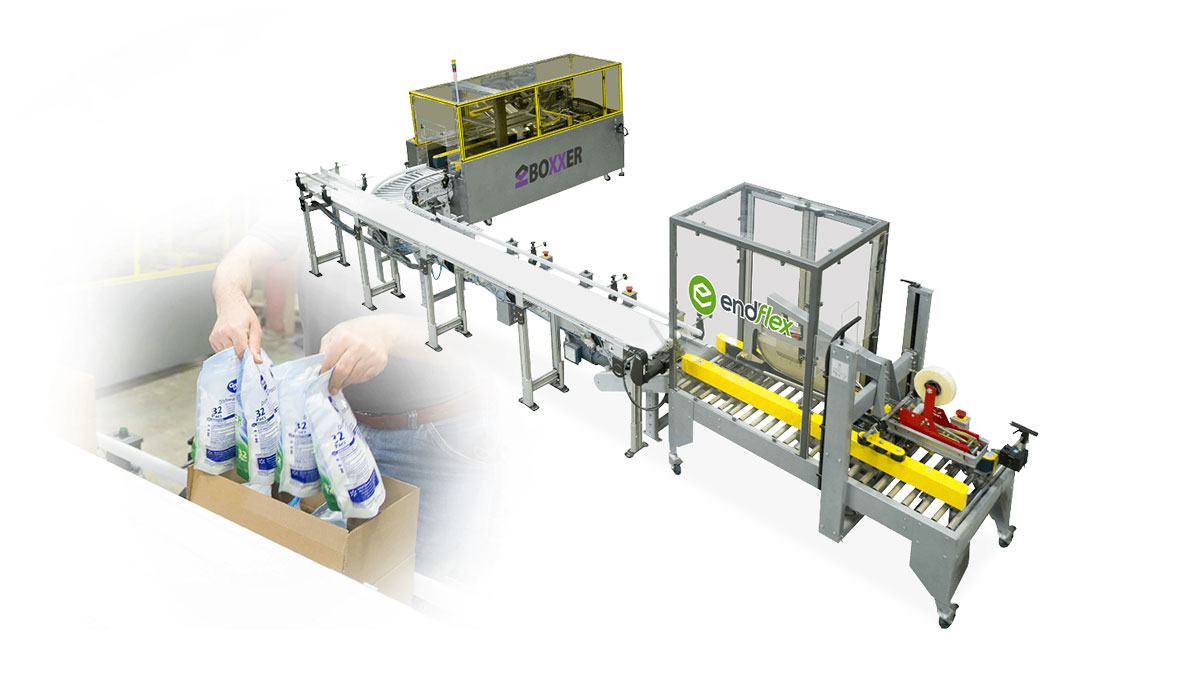

Robotic Case Packing

Robotic case packing is a transformative process in the packaging industry, where automated systems are used to efficiently load products into cases or trays. This technology replaces manual labor, ensuring that products are packed with precision and consistency. By integrating robotic case packing into your production line, you can:

Benefits:

- Increase Speed by automating the packing process to achieve faster throughput and meet high-demand production goals.

- Reduce Labor Expenses and minimize the risk of human error, leading to long-term savings.

- Ensure Uniformity and Accuracy in every case packed, maintaining product quality and integrity.

- Ensure Flexibility by adapting to different packaging configurations and product sizes with ease.

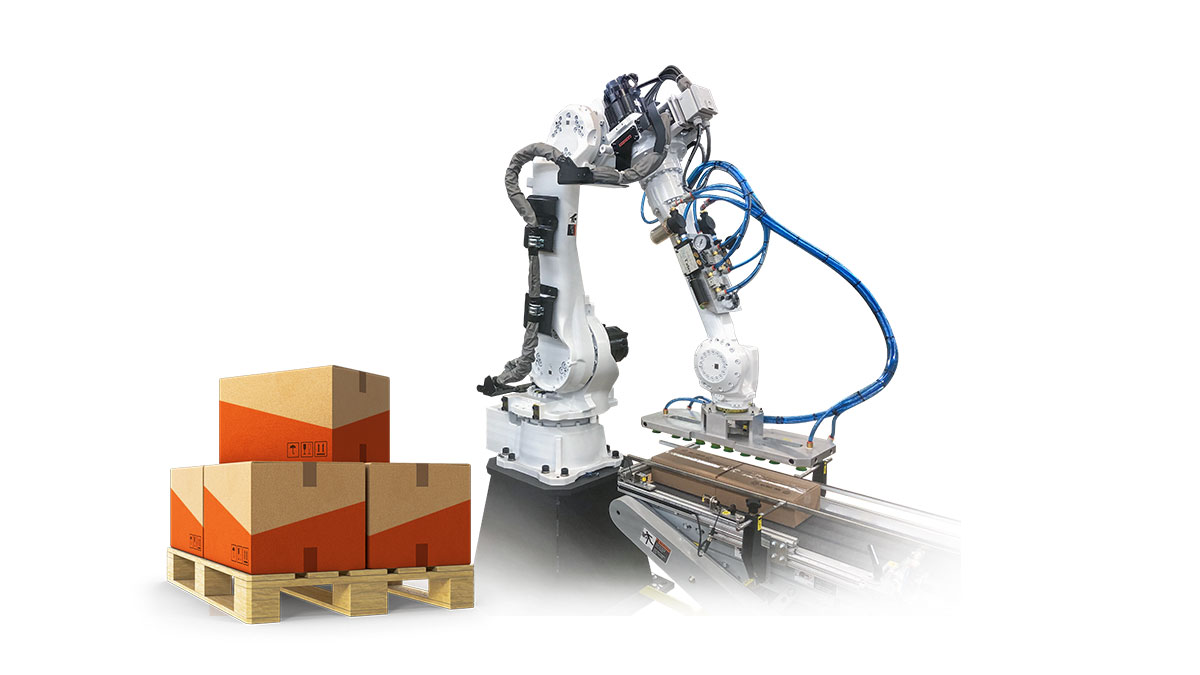

Pick and Place Robots

Pick and place robots are automated machines designed to pick up items from one location and place them in another with precision and speed. These robots are essential in various industries, where they handle repetitive tasks that require accuracy, such as assembling products, sorting materials, and packaging items. By automating these processes, pick and place robots can:

Benefits:

- Achieve High Levels of Accuracy in product handling, reducing waste and rework.

- Increase Efficiency and Speed up the production process by automating repetitive tasks, allowing for higher output and faster cycle times.

- Create Versatility by easily adapting to different tasks and product types, providing flexibility in various applications.

- Decrease Labor Cost by reducing dependency on manual labor, leading to significant cost savings and increased reliability in operations.

Our Solutions

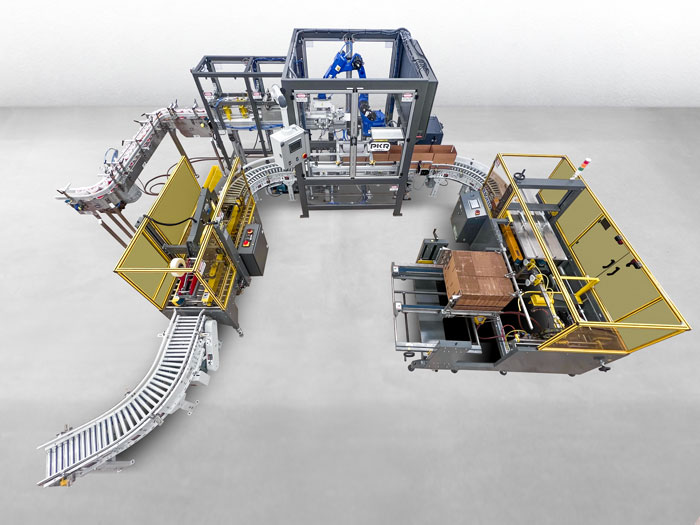

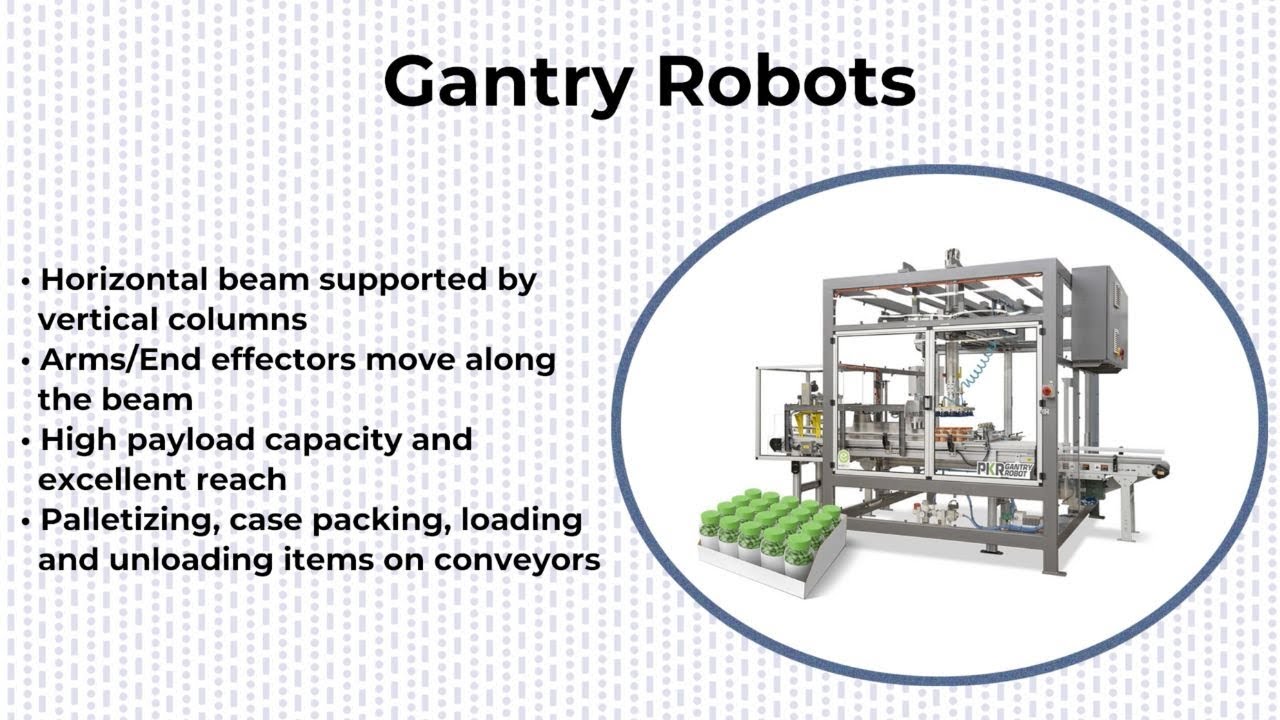

Gantry Robots

Our PKR Gantry Robot is a versatile and efficient solution designed to handle a wide range of products, including jars, cans, bottles, and clamshells. This robotic lop loader excels in precision and speed, making it an ideal choice for industries that require consistent and reliable product handling.

Versatility: Capable of handling various product types and packaging configurations, from jars and cans to bottles and clamshells.

Precision: Equipped with advanced robotic technology that ensures accurate and consistent product placement, minimizing errors and maximizing productivity.

Speed: Designed to operate at high speeds, this gantry robot enhances your production line’s throughput, meeting even the most demanding production schedules.

Durability: Built with high-quality materials to withstand continuous operation in industrial environments, ensuring long-term reliability.

Food and Beverage: Efficiently loads jars, bottles, and cans into cases or trays, ideal for packaging lines in food and beverage manufacturing.

Consumer Goods: Handles a variety of product types with care and precision, making it suitable for diverse consumer goods packaging operations.

Pharmaceuticals: Ensures the safe and accurate loading of bottles and containers, maintaining the integrity and quality of pharmaceutical products.

- Key Features

-

Versatility: Capable of handling various product types and packaging configurations, from jars and cans to bottles and clamshells.

Precision: Equipped with advanced robotic technology that ensures accurate and consistent product placement, minimizing errors and maximizing productivity.

Speed: Designed to operate at high speeds, this gantry robot enhances your production line’s throughput, meeting even the most demanding production schedules.

Durability: Built with high-quality materials to withstand continuous operation in industrial environments, ensuring long-term reliability.

- Applications

-

Food and Beverage: Efficiently loads jars, bottles, and cans into cases or trays, ideal for packaging lines in food and beverage manufacturing.

Consumer Goods: Handles a variety of product types with care and precision, making it suitable for diverse consumer goods packaging operations.

Pharmaceuticals: Ensures the safe and accurate loading of bottles and containers, maintaining the integrity and quality of pharmaceutical products.

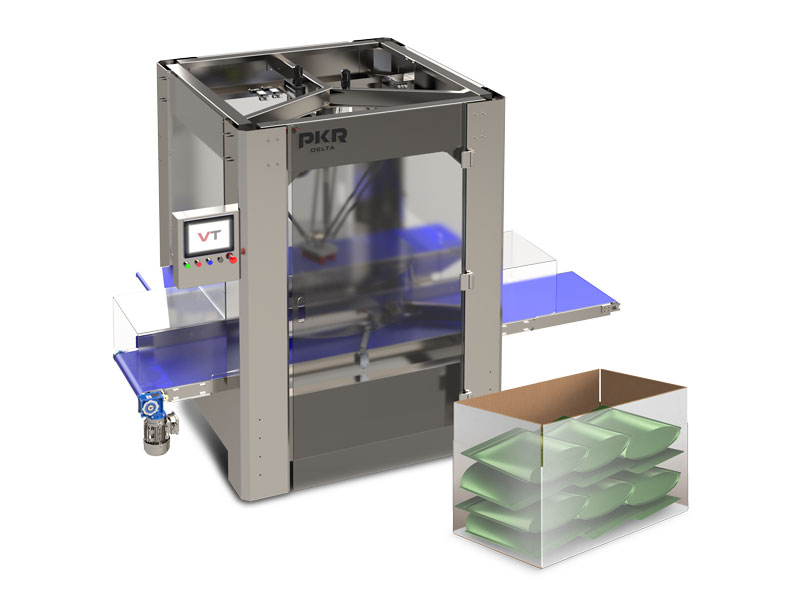

Delta Robots

The PKR Delta Robot is a high-speed, top-loading solution engineered for precise and efficient handling of flexible packages, including bags, pouches, and other lightweight items. With its advanced delta-style robotic arms, this robot offers unmatched accuracy and speed, making it an ideal choice for industries that demand rapid and reliable product placement.

High-Speed Operation: Capable of performing high-speed top-loading tasks, significantly increasing the throughput of your packaging line.

Precision Handling: Designed with delta-style robotic arms that ensure accurate placement of flexible packages, reducing the risk of product damage or misplacement.

Flexibility: Easily adapts to various packaging formats and product sizes, providing versatility across different production requirements.

Compact Design: The compact and lightweight structure allows for easy integration into existing production lines without occupying excessive space.

Food and Beverage: Ideal for top-loading bags, pouches, and other flexible packages in food and beverage production, ensuring consistent and precise placement.

Pharmaceuticals: Suitable for handling small, flexible packages in pharmaceutical packaging operations, maintaining product integrity and accuracy.

Consumer Goods: Efficiently manages the top-loading of various flexible packages, from pouches to bags, across a wide range of consumer goods.

- Key Features

-

High-Speed Operation: Capable of performing high-speed top-loading tasks, significantly increasing the throughput of your packaging line.

Precision Handling: Designed with delta-style robotic arms that ensure accurate placement of flexible packages, reducing the risk of product damage or misplacement.

Flexibility: Easily adapts to various packaging formats and product sizes, providing versatility across different production requirements.

Compact Design: The compact and lightweight structure allows for easy integration into existing production lines without occupying excessive space.

- Applications

-

Food and Beverage: Ideal for top-loading bags, pouches, and other flexible packages in food and beverage production, ensuring consistent and precise placement.

Pharmaceuticals: Suitable for handling small, flexible packages in pharmaceutical packaging operations, maintaining product integrity and accuracy.

Consumer Goods: Efficiently manages the top-loading of various flexible packages, from pouches to bags, across a wide range of consumer goods.

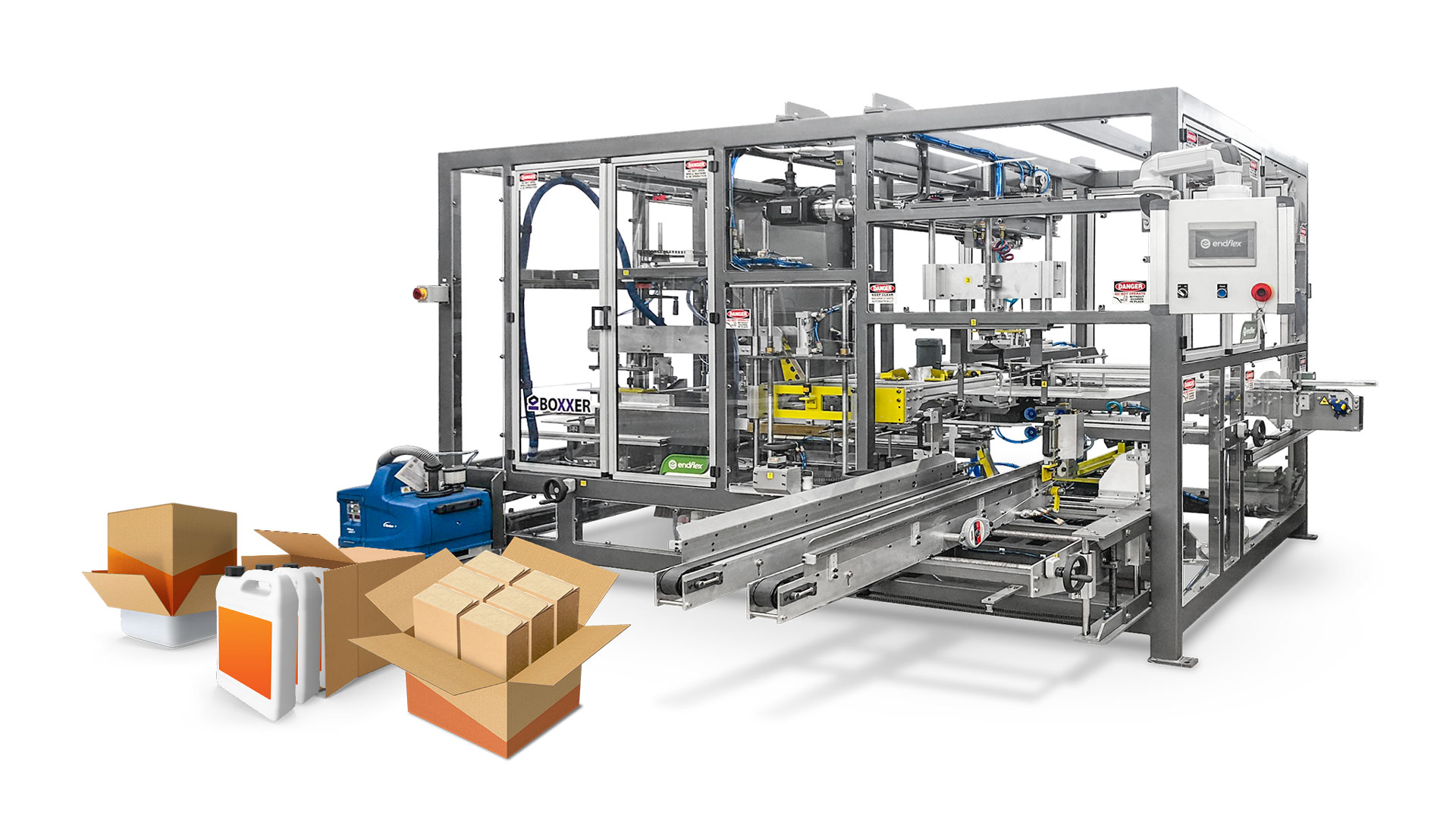

PKR Robot

The PKR Robot is a sophisticated robotic top loader equipped with an articulated arm, specifically designed for environments with limited height. This advanced robot excels in maximizing efficiency and precision in compact spaces, making it an ideal solution for industries that require reliable product handling without compromising on space.

Articulated Arm Design: The flexible articulated arm allows for precise and controlled movements, ensuring accurate product placement even in tight or confined spaces.

Space-Saving Solution: Engineered to operate effectively in areas with limited height, this robot maximizes productivity while minimizing the required footprint.

Versatility: Capable of handling a wide range of product types and packaging formats, providing a flexible solution for various production needs.

High Precision: Designed for consistent and reliable product handling, reducing the likelihood of errors and ensuring smooth operation across the production line.

Food and Beverage: Perfect for top-loading products in compact environments, such as food processing facilities with space constraints.

Pharmaceuticals: Ensures precise and careful handling of delicate products in pharmaceutical packaging, even in facilities with limited vertical space.

Consumer Goods: Versatile enough to handle various consumer products, from small items to larger packages, within restricted spaces.

- Key Features

-

Articulated Arm Design: The flexible articulated arm allows for precise and controlled movements, ensuring accurate product placement even in tight or confined spaces.

Space-Saving Solution: Engineered to operate effectively in areas with limited height, this robot maximizes productivity while minimizing the required footprint.

Versatility: Capable of handling a wide range of product types and packaging formats, providing a flexible solution for various production needs.

High Precision: Designed for consistent and reliable product handling, reducing the likelihood of errors and ensuring smooth operation across the production line.

- Applications

-

Food and Beverage: Perfect for top-loading products in compact environments, such as food processing facilities with space constraints.

Pharmaceuticals: Ensures precise and careful handling of delicate products in pharmaceutical packaging, even in facilities with limited vertical space.

Consumer Goods: Versatile enough to handle various consumer products, from small items to larger packages, within restricted spaces.

Ready to Supercharge Your Production? Contact us for pricing & ROI today.