RayTec Raybox

X-ray container inspection machine

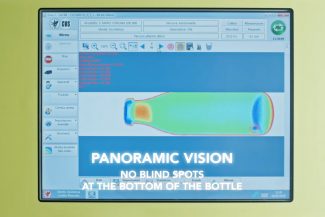

The Raytec Raybox is an X-ray sorting machine designed for packaged cannabis products in rigid containers. X-ray technology effectively detects and rejects various high-density contaminants. The system is calibrated to minimize false rejects, with a target rate of less than 0.3% of inspected products.

Beyond foreign object detection, the Raybox can also inspect for:

- Container shape and integrity (e.g., dents, breaks)

- Filling level accuracy

- Correct positioning of the easy-open side in tinplate cans

Videos

Features

- Equipped with a conveyor belt made of x-ray transparent material.

- palette waste system with electro-pneumatic activation that enables containers of any size to be ejected with high precision.

- 17” color touch-screen monitor

- Max diameter 155 mm [6”]

- Max inspection speed – 100 m/min (Standard 45 m/min) [328 ft/min (Standard 147 ft/min)]

Our RayTec Raybox is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Equipped with a conveyor belt made of x-ray transparent material.

- palette waste system with electro-pneumatic activation that enables containers of any size to be ejected with high precision.

- 17” color touch-screen monitor

- Max diameter 155 mm [6”]

- Max inspection speed – 100 m/min (Standard 45 m/min) [328 ft/min (Standard 147 ft/min)]

-

Ideal Product

-

Our RayTec Raybox is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

RayTec Raybox

X-ray container inspection machine

Videos

The Raytec Raybox is an X-ray sorting machine designed for packaged cannabis products in rigid containers. X-ray technology effectively detects and rejects various high-density contaminants. The system is calibrated to minimize false rejects, with a target rate of less than 0.3% of inspected products.

Beyond foreign object detection, the Raybox can also inspect for:

- Container shape and integrity (e.g., dents, breaks)

- Filling level accuracy

- Correct positioning of the easy-open side in tinplate cans

Features

- Equipped with a conveyor belt made of x-ray transparent material.

- palette waste system with electro-pneumatic activation that enables containers of any size to be ejected with high precision.

- 17” color touch-screen monitor

- Max diameter 155 mm [6”]

- Max inspection speed – 100 m/min (Standard 45 m/min) [328 ft/min (Standard 147 ft/min)]

Our RayTec Raybox is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Equipped with a conveyor belt made of x-ray transparent material.

- palette waste system with electro-pneumatic activation that enables containers of any size to be ejected with high precision.

- 17” color touch-screen monitor

- Max diameter 155 mm [6”]

- Max inspection speed – 100 m/min (Standard 45 m/min) [328 ft/min (Standard 147 ft/min)]

-

Ideal Product

-

Our RayTec Raybox is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.