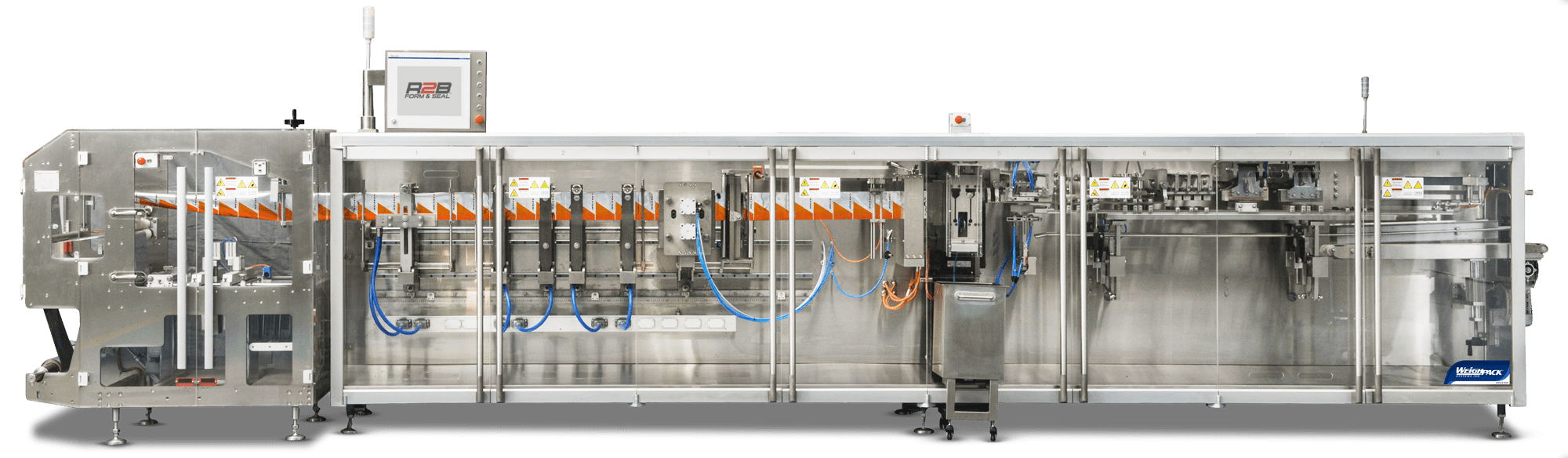

R2B 3600 SIMPLEX

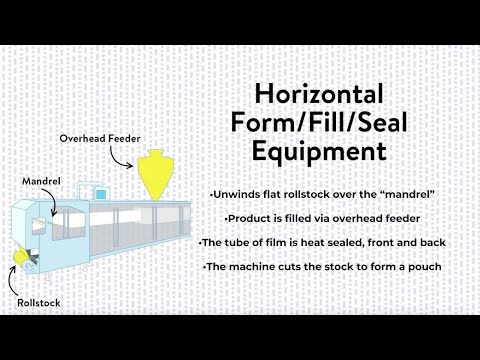

Horizontal Form Fill & Seal Machine

Produce Stunning Pouches from Roll Stock

The high-performance R2B horizontal form fill and seal machine integrates the forming, filling and sealing process into one system.

This fully servo-driven machine can produce stand-up DOY pouches and both 3-sided seal and 4-sided seal pouches with zipper closures as well as shaped pouches requiring die cuts. It is also capable of inserting a corner rigid spout.

The R2B uses laminated roll stock film to create a large variety of pouch styles, thus eliminating the need for premade bags and reducing material cost dramatically; at times realizing savings of up to 30% over purchasing premade packaging.

Available options include gas flush, hole punch, middle capping device, shaped bag molding device, stand-up pouch former, tare notch, vacuum station, zipper applicator and rigid spout inserter.

Ideal applications include foods, pharmaceuticals, life sciences products, beverages, liquids and household care items.

Videos

Features

- AB PLC

- AB color touch screen

- Color touch screen

- Adjustable bag width and length

- Straight flow-through design

- Easy access drive mechanisms

- SMC & Festo sensors

- Festo valves

- Festo vacuum generator

- Integrated exit conveyor

- Encoder positioning logic

- Separate mounted film unwind with air actuated film shaft

- 304 Stainless steel sheet metal

- Heavy duty construction

- Easy access panels

- VFD variable speed control

UP TO 60 PER MINUTE / 200MM WIDE

*Rates subject to package style, type and size

Our R2B 3600 is suited for all industries as your go to horizontal bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- AB PLC

- AB color touch screen

- Color touch screen

- Adjustable bag width and length

- Straight flow-through design

- Easy access drive mechanisms

- SMC & Festo sensors

- Festo valves

- Festo vacuum generator

- Integrated exit conveyor

- Encoder positioning logic

- Separate mounted film unwind with air actuated film shaft

- 304 Stainless steel sheet metal

- Heavy duty construction

- Easy access panels

- VFD variable speed control

UP TO 60 PER MINUTE / 200MM WIDE

*Rates subject to package style, type and size

-

Ideal Markets

-

Our R2B 3600 is suited for all industries as your go to horizontal bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

R2B 3600 SIMPLEX

Horizontal Form Fill & Seal Machine

Produce Stunning Pouches from Roll Stock

The high-performance R2B horizontal form fill and seal machine integrates the forming, filling and sealing process into one system.

This fully servo-driven machine can produce stand-up DOY pouches and both 3-sided seal and 4-sided seal pouches with zipper closures as well as shaped pouches requiring die cuts. It is also capable of inserting a corner rigid spout.

The R2B uses laminated roll stock film to create a large variety of pouch styles, thus eliminating the need for premade bags and reducing material cost dramatically; at times realizing savings of up to 30% over purchasing premade packaging.

Available options include gas flush, hole punch, middle capping device, shaped bag molding device, stand-up pouch former, tare notch, vacuum station, zipper applicator and rigid spout inserter.

Ideal applications include foods, pharmaceuticals, life sciences products, beverages, liquids and household care items.

Features

- AB PLC

- AB color touch screen

- Color touch screen

- Adjustable bag width and length

- Straight flow-through design

- Easy access drive mechanisms

- SMC & Festo sensors

- Festo valves

- Festo vacuum generator

- Integrated exit conveyor

- Encoder positioning logic

- Separate mounted film unwind with air actuated film shaft

- 304 Stainless steel sheet metal

- Heavy duty construction

- Easy access panels

- VFD variable speed control

UP TO 60 PER MINUTE / 200MM WIDE

*Rates subject to package style, type and size

Our R2B 3600 is suited for all industries as your go to horizontal bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- AB PLC

- AB color touch screen

- Color touch screen

- Adjustable bag width and length

- Straight flow-through design

- Easy access drive mechanisms

- SMC & Festo sensors

- Festo valves

- Festo vacuum generator

- Integrated exit conveyor

- Encoder positioning logic

- Separate mounted film unwind with air actuated film shaft

- 304 Stainless steel sheet metal

- Heavy duty construction

- Easy access panels

- VFD variable speed control

UP TO 60 PER MINUTE / 200MM WIDE

*Rates subject to package style, type and size

-

Ideal Markets

-

Our R2B 3600 is suited for all industries as your go to horizontal bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.