Packaging and Packing Systems in Quebec

Quebec is a broad province that encompasses around one-sixth of Canada. Many visitors go directly to Montreal or Quebec City. While those two main cities indeed have many things to offer there’s no harm to exploring other places in the province. For starters, they have Mont-Tremblant, a top ski destination located in the Laurentian Mountains. Aside from skiing, you can also enjoy other activities like snowmobiling, snowshoeing, ice skating, and dogsledding. Another great attraction is the Forillon National Park sitting at the tip of the Gaspe Peninsula. There, you can visit the Cap des Rosiers Lighthouse, the tallest in Canada that also functions as an information center.

If you want to be surrounded with youth and excitement, head over to Old Montreal where visitors can explore the neighborhood’s maze-like streets by bike or foot. It’s a perfect place to shop, dine, and drink. If there’s Old Montreal, then there’s also Old Quebec. This place in Quebec City features architecture dating back centuries and stunning churches and chapels. While it screams archaic, unlike Old Montreal where there’s more than a hint of new, Old Quebec is that one place you shouldn’t miss out.

Understanding horizontal form fill seal (FFS) machines

Horizontal FFS machines are a type of packaging machine that utilizes an innovative technology to form custom pouches, fill it with a solid or liquid product, then seal it through a vacuum sealing technology. These packaging machines are engineered to provide high production speeds while packaging even bulk products. Because these machines function in a fully automatic mode, they are capable of handling everything from bag feeding, filling, and sealing, significantly reducing the amount of manpower it would take to package your products. Overall, investing in fully automatic horizontal packaging machines will help you save money, all the while ensuring that you can package many products in a shorter period.

Speed

With horizontal packaging, bulk quantities are packaged at impressive speeds since these packaging machines normally employ multiple steps altogether. For free-flowing granular products, a horizontal FFS machine can finish more than 2,000 bags per hour.

Package size

While mostly used in the B2B sector due to their ability to produce larger packs, horizontal FFS machines can also be used in retail sectors.

Material properties

These machines can handle clean, dry, free-flowing products. For horizontal packaging systems, accessing the bag material after filling is relatively easy as it can be performed through the machine’s filling spout or by adding more processing steps in the system to help in material settling.

Film size

Some film width variations can be done for horizontal FFS machines. When changing film size, operators can do it without any change parts but within the limits of the machine. In other words, switching from one film size to another is made quicker with horizontal FFS machines.

Cost

Compared to vertical FFS machines, horizontal models are larger, a bit more complex, and more costly. Still, they can also handle more rugged applications and offer lower consumable costs.

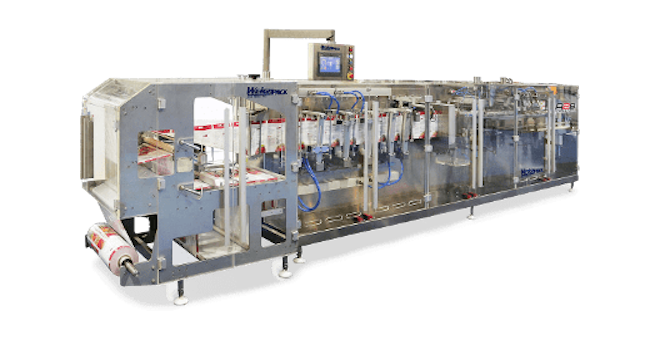

R2B Horizontal FFS Machine from Paxiom

At Paxiom, we offer a wide selection of form fill seal machines, classified into two parts: vertical and horizontal. For our horizontal packaging machines, we have the R2B. This high-performance machine is designed to cut down material unit costs while producing high-speed applications. Since it works to form pouches from a rollstock film, business owners can save up to 30%. Made with servo drives and stainless steel exterior frame, our R2B is incredibly reliable and durable.

To increase the visibility of the forming, filling, and sealing process, we have engineered this horizontal FFS machine with a linear design. This also allows for better accessibility of the machine parts. Additionally, we have included an encoder positioning logic for precise control of the R2B when setting it up and running it. With large access panels, this FFS packaging machine allows for simple set up, cleaning, and servicing. As for the bag styles, our horizontal FFS machines are capable of forming doy bags, 3-sided seal bags, and 4-sided seal bags. You can also configure the machine to produce pouches with or without a zipper enclosure.

Depending on your production needs, the R2B can be configured to include options like middle capper, stand-up pouch forming device, gas flush, vacuum station, and a zipper applicator. Commonly used for producing larger bags, this horizontal FFS machine has a bag size capacity of up to 11 inches long and up to 7.75 inches wide. Other features are heavy-duty construction, easy-access drive mechanisms, color touchscreen, servo drives, and integrated exit conveying machine.