Packaging Machines for Oregon Corporations

Known as the Beaver State, Oregon is a paradise for cultural and outdoor lovers. Whichever part of the state you are, there’s always something interesting to enjoy yourself with. Needless to say, there are tons of things to love in this state. Want to feel like you’re in Japan? Go to Portland Japanese Garden and get a taste of the Japanese in this dreamy, zen-like garden. You can also experience a variety of cultural activities be it tea ceremonies or woodblock exhibitions. Another cool place in Oregon is Thor’s Well at Yachats.

Seated on the edge of the Oregon coast, this mighty, gaping sinkhole is a sight to behold. At first glance, you’d think that it’s swallowing up the sea around it, but Thor’s Well is actually a 20 ft deep hole in the rock. Whether you’re in Oregon for a summer or winter getaway, Mt. Hood is the place for you. Standing tall at 11,249 ft, this stratovolcano is the largest peak in Oregon. It’s a premier destination during summer where hikers and campers can explore its stark beauty and is popular for its snow sports during winter.

The basics of check weighing

Typically designed for industrial and commercial applications, check weighing is an important feature on numerous floor and bench scales. In essence, check-weighing refers to the comparison of weight to know whether or not the weight is within preset limits. For instance, if you sell grapefruits in boxes, you’d want to ensure that all cartons have the same weight so customers pay the same prices for the same amount. So, if your boxes of products are labeled 1 pound, you can just place each box on the scaling machine to see if it’s under, over, or within your preferred weight range without having to weigh.

Common features of a checkweigher machine

Typical check weighing can be done using a weighing indicator and a platform scale. Scales that come with check weighing normally include features like a colored LED display that lights up on the machine’s indicator, an audible alarm to signal if the weight is under, over, or just right within the preset limits. Other machines for check weighing are also equipped with additional features such as automatic tare and zero-tracking to boost repetitive check weighing tasks. On the other hand, scales that are engineered specifically for check weighing can be used with selectable digital filtering or optional relay boxes for light towers.

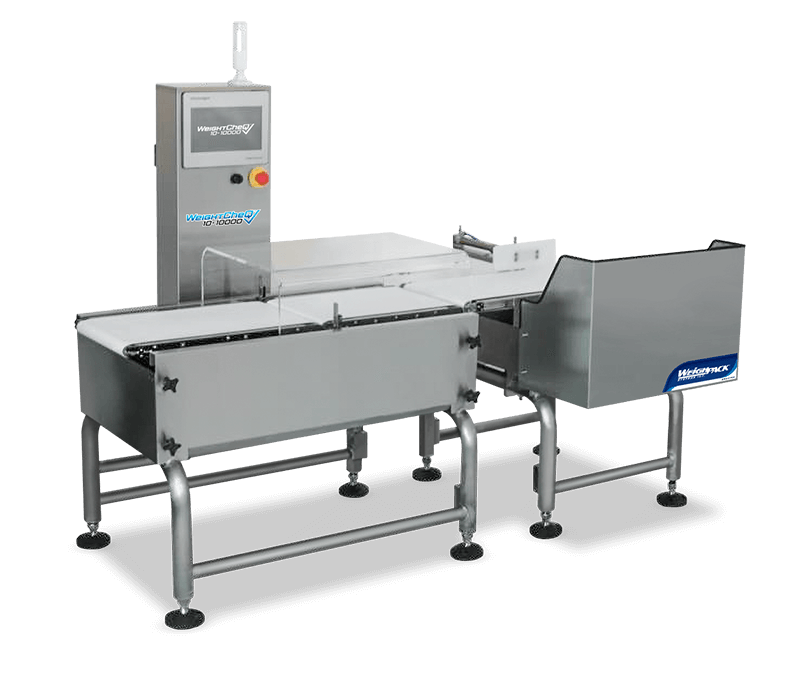

Check-weigh your packages with Paxiom’s WeightCheQ

This type of end-of-line packaging machinery is designed to automatically weight-check your cartons, bottles, bags, cases, and other containers with ease. Coming from a reputable packaging manufacturer like Paxiom, we have made sure that our check weighing solutions deliver accuracy and speed on top of simple operation. What’s more, we have designed the WeightCheQ to be easily added into your existing packaging system, including automatic container filling, bagging, flow wrapping, and case filling.

Our WeightCheQ product line is a family of three check weighing machines. All models share the same features such as:

- Simple editing and switching due to product presets

- Quick speed due to German high-speed load cell

- Easy operation with its user-friendly interface

- A self-learning ability and weighing parameter settings

- Simple data management thanks to its USB export function and weighing history query

- Improves stability because of its dynamic weight tracking

- Available with pusher, blower, or down conveyor

- Delivers a strong and durable performance with its 304 stainless steel frame

Different models of WeightChecQ

WeightCheQ 3-1000

– maximum throughput of 150 pcs per minute

– a weighing range of 3 to 1000 grams

– two alarm modes: audible and visual

WeightCheQ 10-4000

– maximum throughput of 150 pcs per minute

– a weighing range of 3 to 4000 grams

– two alarm modes: audible and visual

WeightCheQ 10-10000

– maximum throughput of 100 pcs per minute

– a weighing range of 10 to 10000 grams

– two alarm modes: audible and visual

When choosing a check weighing scale, it’s always important to think about the operation conditions and applications of your future weighing scale. For example, if you’re only using it to, say crate occasional goody bags, then having a simpler scale is enough. If you’re more concerned about the quality, scales that will speed up and simplify your tasks are good options, as they will also save you money and time in the long run. Other things to consider are the size of the scale, its IP rating, and other additional applications.