Packaging Machine Systems in New Brunswick

Epic road trips are common in Canada, especially in the province of New Brunswick. Looking for scenic sights and outdoor adventures? Then this East Coast gem has you covered. From ocean to city, New Brunswick has so many things to offer. To start with, visit the Acadian Historical Village in Caraquet where you can witness firsthand how Acadians live centuries before. And speaking of history, consider going to King’s Landing to know more about the province’s history and the English who lived and farmed the land. Home to the Bay of Fundy, New Brunswick has the highest tides in the world that could rise to 39 feet twice every day.

The bay can be explored in several ways such as ocean walking, boating, or cliff rappelling. Also, make sure to stop by at Kingsbrae Garden that features over 50,000 perennials in themed gardens. Beyond the flowers and plants, you’ll want to check out the Dutch windmill and explore the cedar maze. And of course, the province also has that good ole wooden lighthouse, Swallowtail Lightstation in Grand Manan Island constructed in 1860, you can use the observation area to clearly view the lighthouse from a distance. You can also walk right up to the structure if you wish.

What is a rotary indexing machine?

In essence, rotary indexing is a type of packaging machinery that moves parts and components through an assembly cell during the manufacturing process in as high efficiency as possible. This indexing equipment rotates items to certain positions, either variable or fixed. Rotary indexing machines are commonly used within the manufacturing space of sectors like automotive, food and beverage, medical, and many more.

Rotary indexing conveyors as container fillers

At Paxiom, we manufacture a diverse range of filling machines that are capable of handling rigid containers. Aside from weigh-filling solutions, we also have capping, case loading, labeling, and robotic palletizing.

Our rigid container packaging machines are perfect for protecting your products while remaining professional-looking. Rigid containers include plastic and glass jars and bottles, boxes, tins, cans, wood, plastic pots and tubes, and drums. While they vary a lot in physical appearance, they’re very important as they provide physical protection to the contents that are not provided by flexible packaging. Most rigid containers are strong due to the number of materials used to produce them, which makes them more costly than flexible packaging.

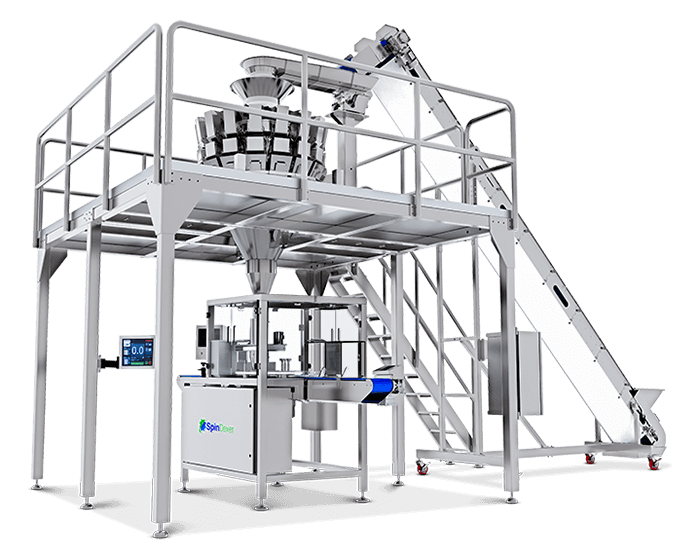

Commonly used for products like powders, fresh produce, snack foods, confections, and coffee, our rigid container filler machines are all engineered to work at high speeds while also offering simple operation. Here’s our SpinDexer line of container filler packaging machinery:

SpinDexer with Traveling Funnels

With a compact design and simple operation, this rigid container filling machine can fill various kinds of products into containers at a high speed. It features PLC-based controls so the operator can access all functions and controls using a color touchscreen. Doing so will ensure that there’s a synchronized timing among the moving parts. This certain model of rotary indexing conveyor has a size range of up to 4.25 inches in bottom diameter. Other features include totally enclosed safety covers, infeed or discharge conveyor, stainless steel contact parts, fully adjustable side rails, and more.

SpinDexer XL with Travelling Funnels

Our SpinDexer XL has a size range of 4.25 inches to 9 inches in the bottom diameter. Like the previous model, it features a compact design and is operator-friendly. Equipped with servo drives on top of a stainless steel frame, our rotary indexing conveyor allows the operator to have total control over the rigid container. Moreover, functions like acceleration, deceleration, and braking can be easily configured and set up according to certain container characteristics. It comes with a color touchscreen, sensing devices for no-container, no-fill function, safety switches, single station fill spout, and Lexan safety covers. If you wish, you can interface the SpinDexer with a weighing machine.

SpinDexer 1800

Designed to provide quick changeovers, the SpinDexer features tool-less removable funneling and starwheel to allow easy access and quick sanitation. It’s capable of filling pharmaceuticals and nutraceuticals products into a wide range of rigid containers. Special functions like reject station and upstream bottle stops are added to the machine for more convenience. Our SpinDexer 1800 also has a series of sensors to provide to boost the efficiency of the machine, which in turn, leads to increased throughput. Readily interfaced with auxiliary packaging machinery, this rotary conveyor machine can work with our PrimoLinear and Star Auger machines.