Bulk Packing and Packaging Machines in Nevada

Admit it, the first thing that crosses your mind when you think of Nevada is Las Vegas. Sure, that’s completely valid, but it’s also important to note that Nevada is so much more than just being the state where Las Vegas belongs to. There’s a multitude of adventures in this Silver State ranging from waterfalls, national parks, open spaces to historic sites and towns, and arts and entertainment. Listed on top of the must-visit places in Nevada is the Hoover Dam that contains Lake Mead, which is the largest reservoir in the country and the source of hydroelectric power to much of Nevada, California, and Arizona.

Enclosed by snow-capped mountains most times, the blue waters of Lake Tahoe are a sight to behold. This freshwater is located high in the Sierra Nevada Mountains and is a famous destination, be it in summer, winter, or any time of the year. Another outdoor spot you must see is the Valley of Fire State Park with its wide vistas of vibrant stone waves and dramatic rock formations. For art lovers, check out The Mob Museum in Las Vegas. There, you can learn the stories of organized crime in America from the late 19th century and how it affected the country over the last century.

Bulk packaging vs Retail packaging

Bulk packaging is when you package many products of the same kind into a single packaging box or container or create a huge packaging box of smaller containers. On the flip side, retail packaging refers to packaging made for the end consumer that will consume the goods after opening the packaging. It also refers to wholesale retail boxes. Bulk packaging is mostly used by manufacturers who want to transport a huge quantity of products to their distributors. Whereas in retail packaging, it’s made to deliver pleasant-looking packages to attract consumers to buy them. Retail boxes or containers are also packed inside the bulk packaging box or container.

With bulk packaging, materials used are carefully picked since they are expected to provide more layers of protection for numerous products inside them. For starters, bulk packaging has to protect the goods from water and moisture. This packaging should also prevent mold and mildew buildup. Lastly, odors should be unable to pass between pouches or bags when transported or stored close to each other. Doing all these will ensure that quality products reach consumers.

Paxiom offers a great selection of bulk packaging machinery

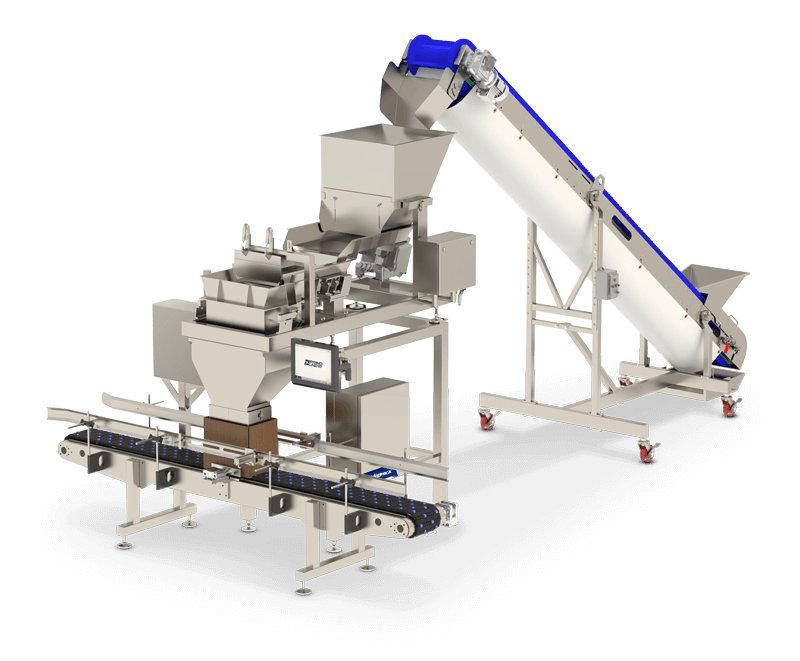

Our product line of bulk packaging machines ranges from bagging and packaging to case filling and packing. Bulk applications can be up to 50 lbs. Our bulk packaging machines are manufactured based on your specific budget, package style, footprint, and production requirements. Let’s learn more about our bulk packaging solutions below:

Bulk horizontal bagging and packaging

Our horizontal packaging machines are capable of running on a large volume of products. Engineered for automation, these bulk packaging machines can work on your laminated or polyethylene bags and pouches. Since they’re a horizontal type of bagger, they don’t create a bag, but rather, work by opening, filling, and sealing your pre-made bags. Wicket pouches are also commonly used in our bulk packaging applications since they’re very flexible and versatile. Wicket packaging works by using pre-made wicket pouches that are loaded into the machine for filling. After filling the wicket bags, they are automatically removed from the wicket holder then sealed.

Bulk case and tote filling

Increase your profits and accomplish accurate fills with our case filling machines. Our easy-to-use and easy-to-clean PrimoLinear is designed to provide bulk net with filling applications. It’s engineered to also work with our box indexing conveyor. This way, you can have a whole packaging system to accomplish your bulk packaging needs. The PrimoLinear operates on corrugated boxes and can fill up to 50 lbs of products. With our leading-edge technology, this packaging machine comes with smart PC controls that provide great features like unlimited recipe storage and handy software like Skype and Windows. We also have a net weigh-filler that runs on products of up to 20,000 lbs per hour.

Bulk vertical bagging

Finally, we also have our product line of vertical baggers for your bulk packaging. Includes a large color display and user-friendly PLC controls, our most popular models are the VerTek 1600 and VerTek 2400 as they are designed to produce huge bag sizes, which are ideal for bulk packaging. Our vertical packaging machinery can form pillow bags and gusseted pouches, with or without a zipper insert.