Packaging Machine Systems in Louisiana

The Crescent City of New Orleans is the top 1 destination in Louisiana. While there’s indeed a plethora of things to enjoy in this city, you might as well grab this chance to also go outside New Orleans and explore the other treasures of Louisiana. Located only a few hours west of New Orleans is Cajun Country where you can experience the unique culture of Acadians while also setting foot in other places like Lafayette, Eunice, and Mamou. Another special place you’d want to check out is Natchitoches, a charming town that’s draped with magnolia and moss. There, you can see the lovely French Creole townhouses and other buildings that date back to the 1700s

Ever heard of Louisiana’s Bird City? What about Tabasco sauce? Avery Island is most popular for two things: as a bird sanctuary and as the home of Tabasco sauce. This wildlife refuge has been developed over several decades and is currently a migration site for around 100,000 egrets. Another must-see attraction is the Rip Van Winkle Gardens in New Iberia. These 20-acre semi-tropical gardens surround the historic Joseph Jefferson Mansion, originating back to 1870.

Food service packaging

Branding is important in the food service industry. One of the reasons is because brand personality perceptions remarkably influence a customer’s loyalty, preference, and positive word-of-mouth marketing. Now, how can food service companies create branding that will make an impression on their customers? One of the most effective ways is to use branded packaging. The packaging is one of the main factors that encourage repeat sales, with more influence than online reviews, TV ads, and even recommendations from friends. As such, it’s essential for branded packaging to be functional and at the same time, convey a unified, unique brand personality that will distinguish an establishment from its competitors.

For many food service brands, having a packaging that’s aesthetically-pleasing and functional is almost as important as making the food products themselves. That said, some food service establishments fail to satisfy their consumers with their poor packaging. Poor packaging can mean several things such as 1) packaging that’s hard to close or re-seal, 2) packaging that spills, breaks, or leaks, and 3) packaging that restricts the consumer from finishing all the product or doling out a certain amount of the product. On the flips side, consumers like attractive-looking and easy-to-use branded packaging, which in turn, helps increase revenues.

Bulk packaging

Bulk packaging is a major operation for many businesses such as those in the agricultural industry. For starters, a bulk packaging system must be capable of handling various kinds of products and package them as accurately and efficiently as possible before transport. Moreover, manually filling bulk bags or containers takes up too much energy, time, and manpower. As a result, this increases the risk of product wastage. But if you automate your bulk packaging process, you can save costs and time.

It will also help prevent workplace accidents associated with manual, labor-extensive production processes. Your workers won’t have to manually move packaging machines, close filled bags, or use robust equipment to transfer packages, thus, lowering the risk of injury. Automated bulk packaging also gives you more control than you’d ever get from a manual system. For instance, a fully automated bulk packaging machine can be set to reject containers that don’t have enough product or alert the operator to any issue with packaging. In other words, automating your packaging line minimizes downtime and increases your productivity.

Paxiom’s bulk and food service packaging

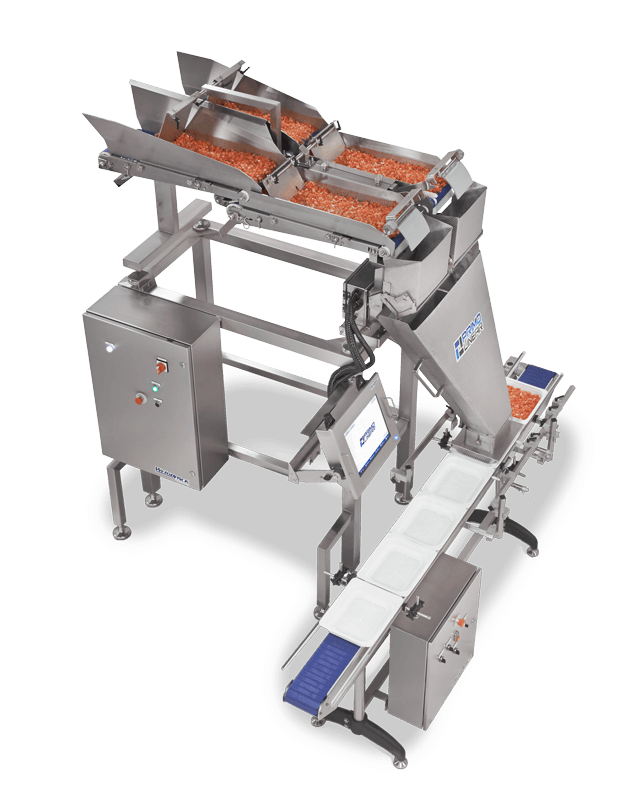

We at Paxiom manufacture a great selection of packaging machines engineered for your bulk and food service filling applications. Products weighing from 5 to 50 lbs are commonly filled into bags, containers, or corrugated cases using our bulk packaging machines. Our family of bulk packaging machinery comes in many models that will cater to your package style, production needs, and budgets.

1.Weigh-filling cases

Boost your profitability while ensuring that accurate fills are achieved with our PrimoLinear filling machine. Works as a bulk net weigher, you can pair this packaging machine with our box indexing conveyor so you can create a complete packaging system that works best for bulk applications.

2. Premade bag filling

Another packaging solution that can match your bulk needs is our premade pouch filling. Composed of a series of horizontal baggers, these machines are designed to fill and seal your pre-made wicket bags.

3.Vertical bagging

Lastly, we also have our vertical form fill and seal solution that’s capable of performing bulk packaging. These vertical bagging machines are specifically made to work on large bag sizes used in bulk applications.