Meet the JuanaRoll®

The first high performance automatic pre roll machine

Engineered for the sophisticated LP, who appreciates quality, mechanical ingenuity and industry leading software. Chosen by the world’s leading LP’s. Schedule an in-person or online demonstration now.

Stop Producing Joints by Hand

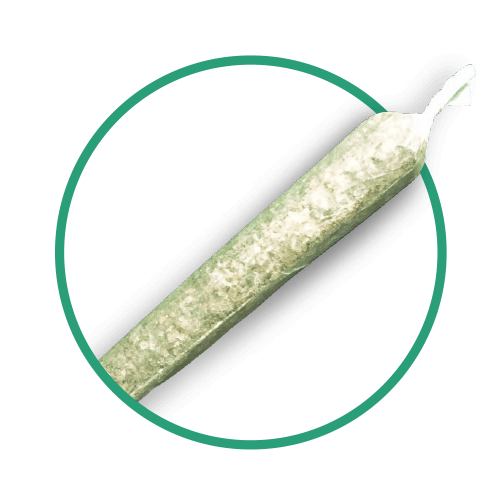

Stop giving away margin by filling pre rolls by hand or with volumetric knock boxes. Introducing the high performance JuanaRoll® pre roll joint packaging machine chosen by the industries leading LP’s.

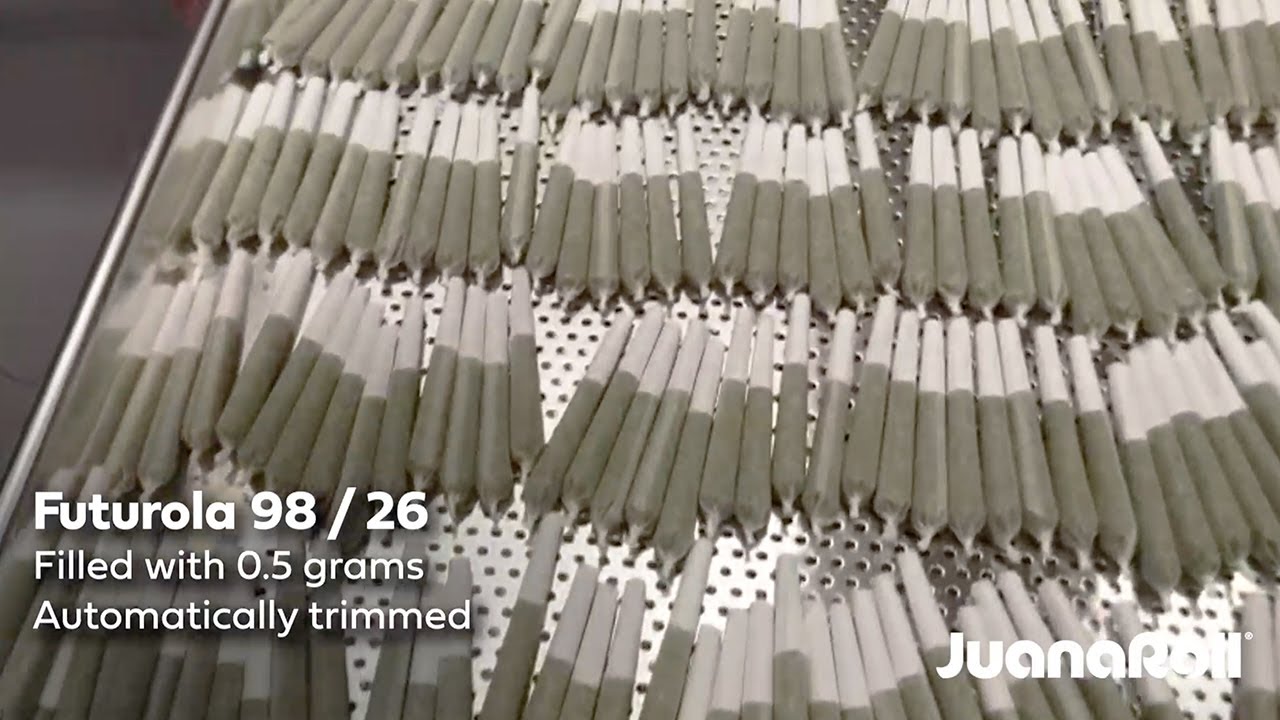

Automatically weigh, fill, compact & twist up to 4,000 pre-rolled cones per hour and stop hiring more hand labor to keep up with demand.

Mechanical Features

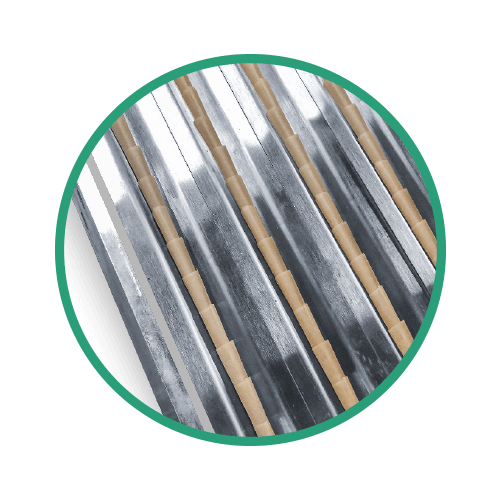

● Easy to load cone magazine

● Weigh filling system (not volumetric!)

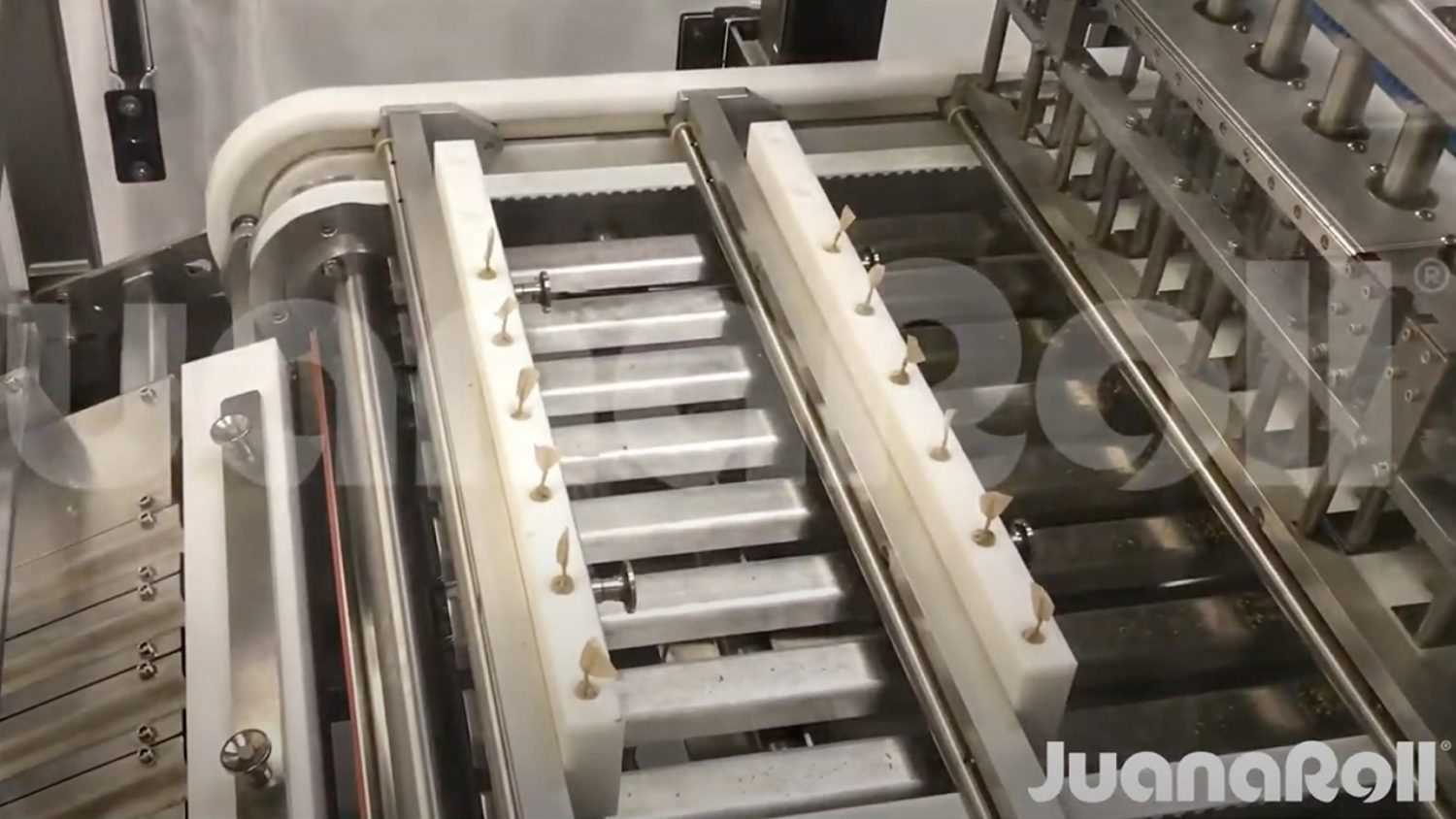

● Compacting station

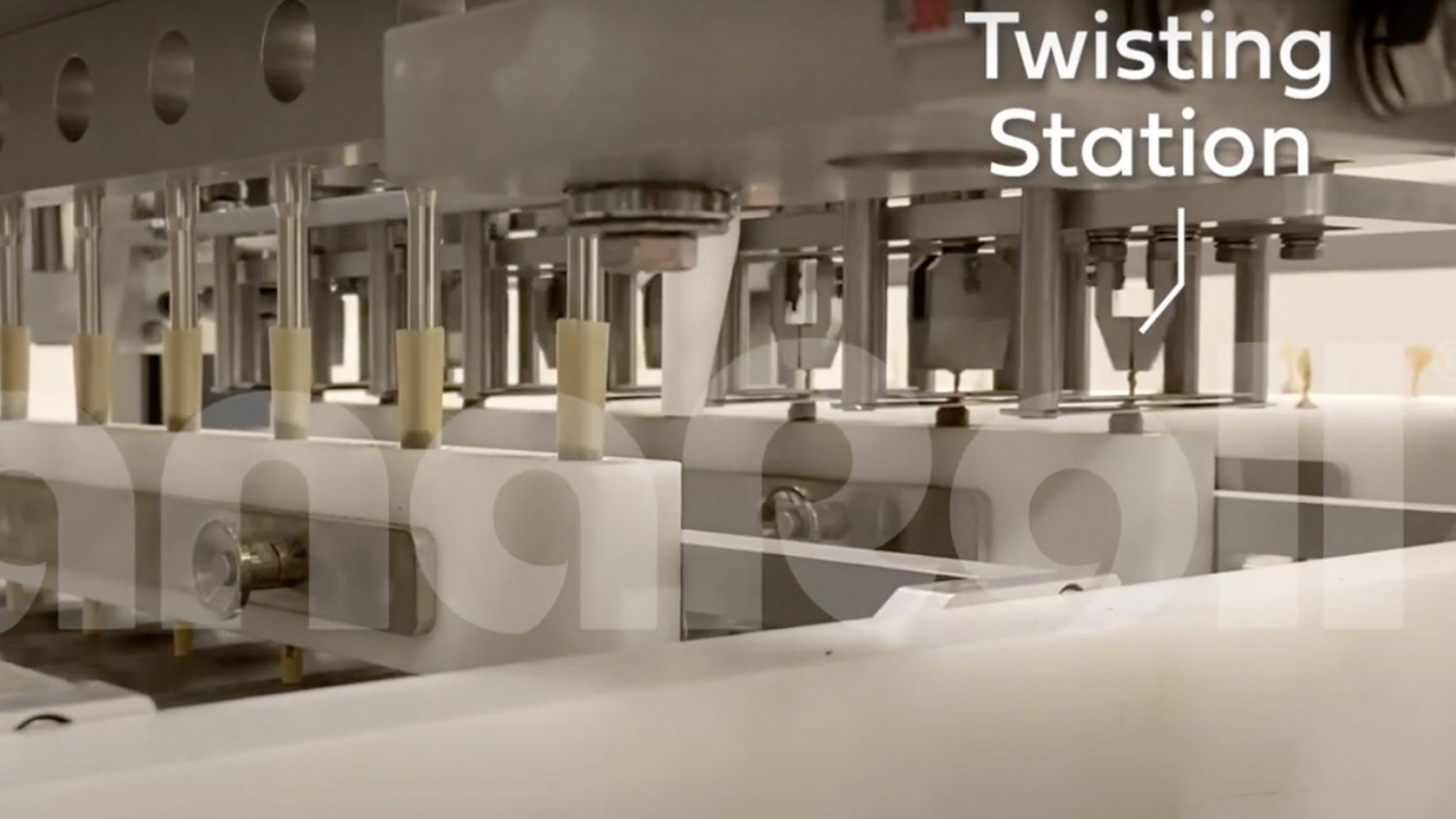

● Twisting station

● Servo driven

● Stainless steel frame

● Stainless steel contact parts

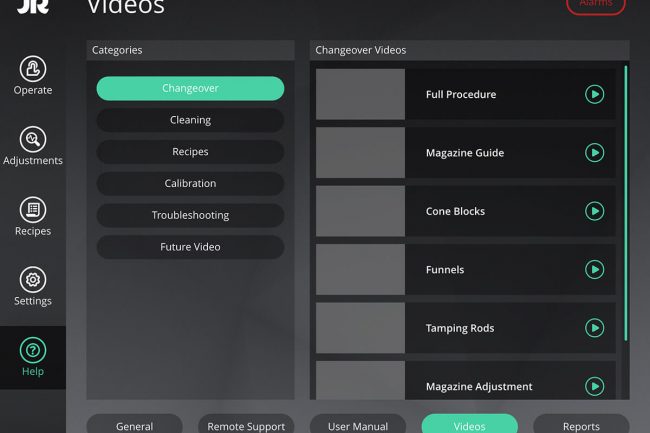

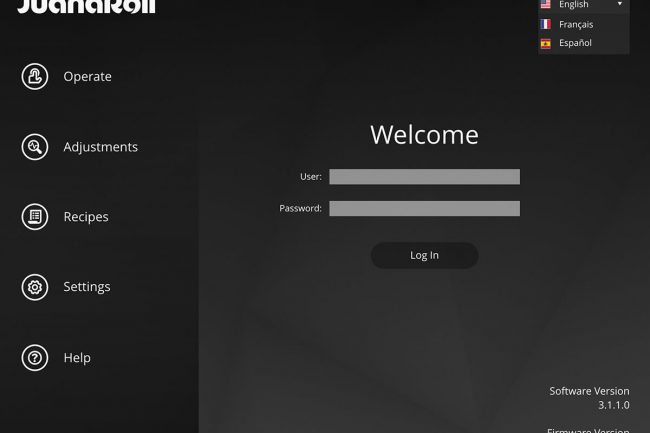

Controls Features

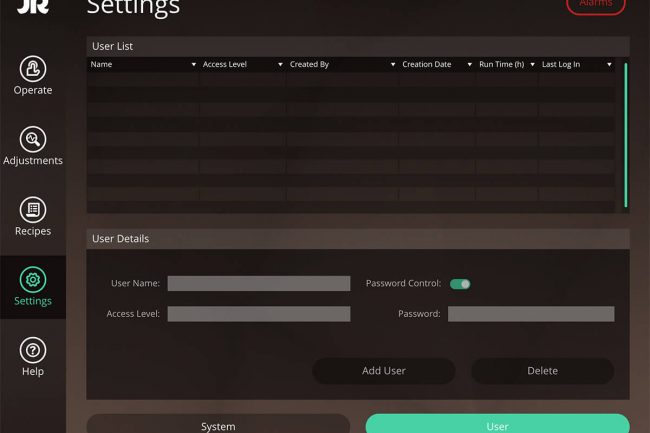

● 15″ color PC touch screen

● Windows operating system

● Real time production reporting

● Import / Export data via USB

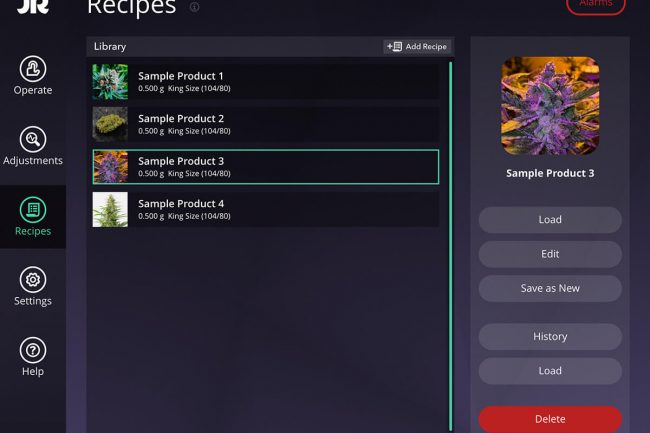

● Unlimited recipe set-ups

● Run multiple weights or strains at the same time

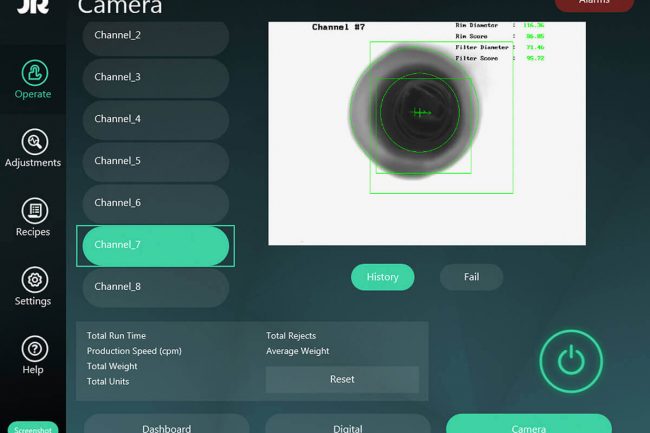

● Digital camera and online support

Also

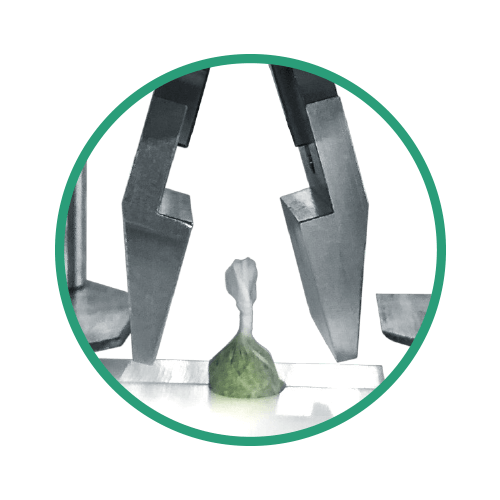

Integrated PreCheQ™

prior to cone fill

No cone – no fill detection

Cone open camera

vision system

Compaction station

Production Reporting

Online Support