Packaging Machine Systems For Georgia Businesses

As if being the Peach State isn’t enough, Georgia is also the nation’s top producer of peanuts, pecans, and Vidalia onions. The state of Georgia is the epitome of southern culture, gladly showcasing the long list of “south things” it has to offer to its visitors. One of these is the Stone Mountain Park, a 3-200 acre space where you can witness the world’s largest laser-light show during summer. Do you think you’ve tried a peach, already? Nah, you need to eat a Georgia peach as there’s a reason why this state takes great pride in its peaches. Fort Valley or Musella–take your pick. Either way, you can find there one of Georgia’s largest and oldest peach orchards.

Like all states in the country, Georgia is never without its own treasured museum. The Booth Western Art Museum in Cartersville is one of GA’s hidden gems, with its largest permanent exhibit of Western art in the whole country. You may also want to check off another “largest attraction” in your bucket list by visiting Georgia Aquarium in Atlanta. It’s the largest aquarium in the Western Hemisphere wherein you can see expansive and stunning displays of marine life.

Benefits of using stand-up pouches

Whether you’re launching a new product or revitalizing your existing product line, using pre-made stand-up pouches for your packaging can make a world of difference. Some of the advantages of using stand-up pouches for your products are:

- They match with consumer lifestyle trends, especially since the on-the-go consumers now prefer lightweight pouches because they’re easy to carry, store, and reseal.

- Many pre-made pouches make it easy to dispense and use the products, allowing complete emptying of the product, unlike with rigid packaging

- Many consumers see stand-up bags as an indicator of a premium quality product

- Millennials are used to seeing juices in pouches, thus, they are more drawn to pouches than any preceding generation.

- All the convenient benefits of stand-up pouches provide value for consumers, ultimately resulting in increased product sales.

Paxiom for Premade Pouch Filling Solutions

At Paxiom, we have the largest product line of premade pouch filling machines, be it for retail, wholesale, or bulk packaging. Our filling machines are also configured for all package budgets and styles and production speeds. For our family of bag filler for laminated pouches with zipper closures, we have our Swifty Bagger series.

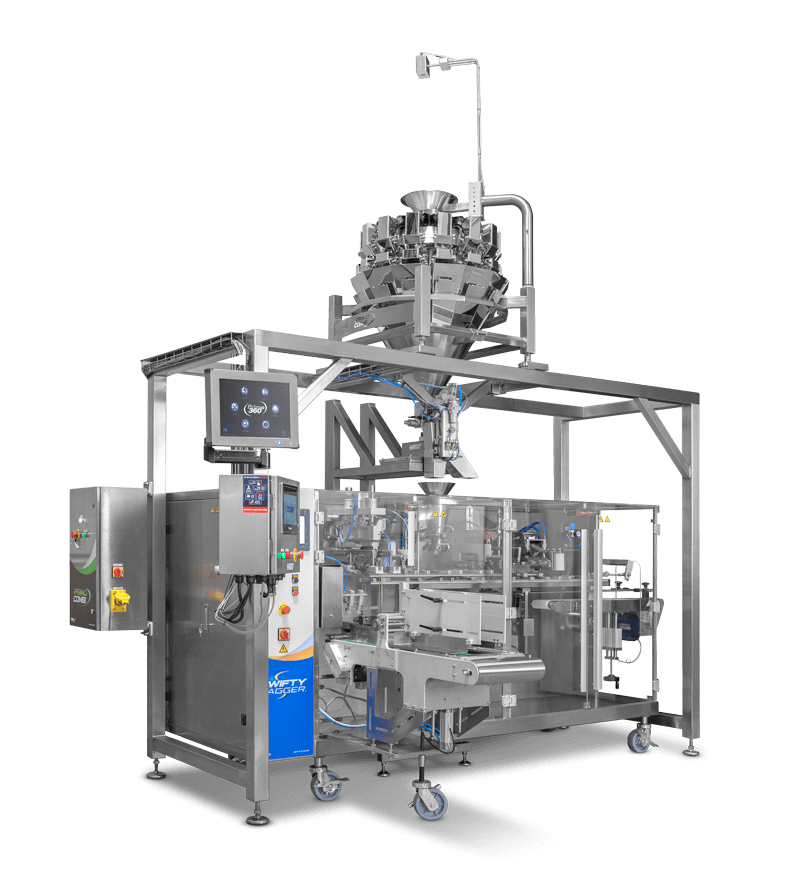

Swifty Bagger Rotary Duplex

Engineered for high-speed filling rates, these servo-driven pouch machines come with stainless steel construction, a highly accessible bag magazine, a bag shaker, and an automatic zipper opening device. Our Rotary Duplex packaging machine is capable of delivering an impressive mechanical rate of up to 4,800 bags per hour.

Swifty Bagger 3600 & 1200

For medium to high-speed filling rates, we have the Swifty Bagger 3600 and 1200. These packaging machines are designed with a unique straight line so the operator can see the entirety of the packaging process. This also simplifies the Swifty Bagger’s operation, cleaning, and servicing. Our pre-made pouch bagger 3600 and 1200 has mechanical rates of up to 2,700 bags per hour.

Swifty Bagger Mini

With mechanical rates of up to 1,000 bags per hour, the Swifty Mini is ideal for filling compact pre-made pouches. It has the smallest footprint out of all our packaging machines, using up only 10 square feet of the floor space. On top of that, it can be easily configured to work alongside your current production line. Lastly, the Swifty Mini can be integrated with our auxiliary filling solutions like net weighing, auger filling, and multi-head weighing.

Swifty Bagger Junior

Capable of filling 900 bags per hour, the Swifty Junior is engineered to open, fill and seal your stand-up pouches in one automatic process. It’s also easy to use and integrate into a current production line. This automatic bag filler can work with other auxiliary fillers like a net weigher, auger filler, and a multi-head weigher.

Picking between premade pouches and form-fill-seal pouches

Pre-made pouches, in a nutshell, are fillable and fully-formed bags while form-fill-seal (FFS) pouches involve the purchase of flexible roll stock and forming that rollstock into bags using an FFS machine. With pre-made pouches, the cost of entry is remarkably lower as well as the product waste. There are also more pouch features available and can operate on several bag sizes and shapes. Pre-made pouches are made by experts in flexible packaging and many of them are constantly investing in new pouching technology and materials.