EZ Glue

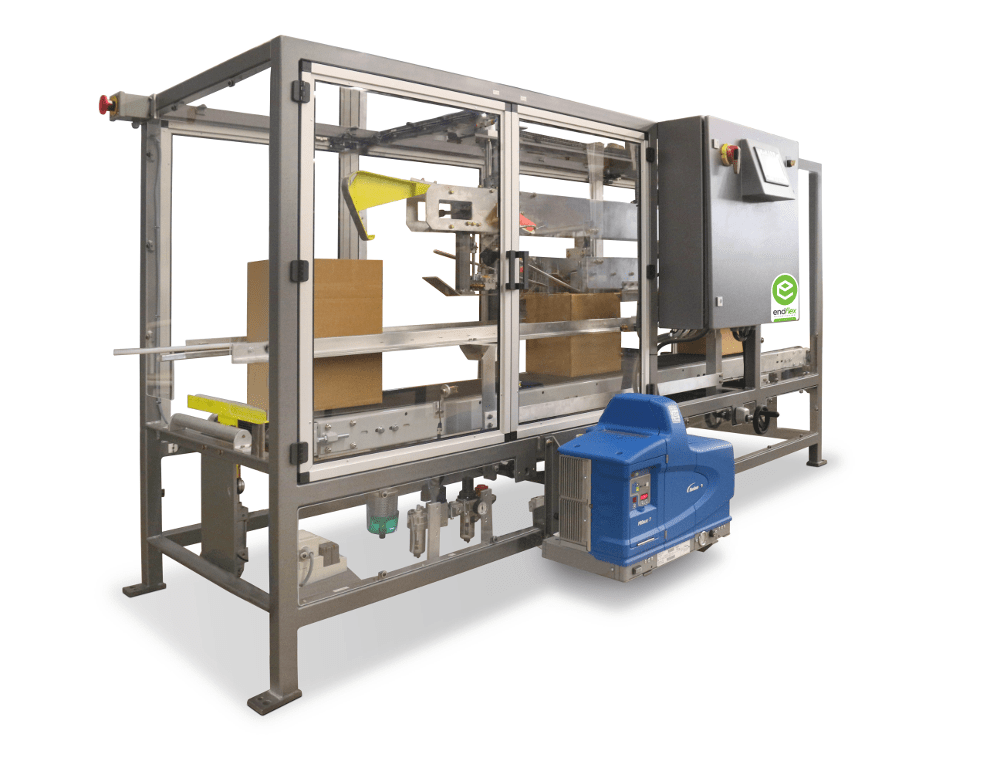

Hot Melt Glue Case or Tray Sealers

EZ-Glue case and tray sealers will take the erected box with product and seal the top of the case with hot melt glue. The case will come from the conveyor, where the case will be stopped by the box stop. The box then transfers through the machine. As the box travels through the machine, the front minor flap and the rear minor flap will be tucked into the box. Glue will be applied to the minor flaps and, at the same time, the minor flaps will be folded over the top of the case. The case will then travel under a set of compression rollers sealing the top of the case.

Videos

EZ Glue Case Max Mechanical Rates:

CS-FB (Flight Bar): 40 cycles per minute

CS-BNB (Bag-in-Box):22 cycles per minute

CS-BD (Belt Drive): 22 cycles per minute

*Rates subject to package style, type and size

Our Poplok tray forming machine is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

EZ Glue Case Max Mechanical Rates:

CS-FB (Flight Bar): 40 cycles per minute

CS-BNB (Bag-in-Box):22 cycles per minute

CS-BD (Belt Drive): 22 cycles per minute

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Poplok tray forming machine is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

EZ Glue

Hot Melt Glue Case or Tray Sealers

Videos

EZ-Glue case and tray sealers will take the erected box with product and seal the top of the case with hot melt glue. The case will come from the conveyor, where the case will be stopped by the box stop. The box then transfers through the machine. As the box travels through the machine, the front minor flap and the rear minor flap will be tucked into the box. Glue will be applied to the minor flaps and, at the same time, the minor flaps will be folded over the top of the case. The case will then travel under a set of compression rollers sealing the top of the case.

EZ Glue Case Max Mechanical Rates:

CS-FB (Flight Bar): 40 cycles per minute

CS-BNB (Bag-in-Box):22 cycles per minute

CS-BD (Belt Drive): 22 cycles per minute

*Rates subject to package style, type and size

Our Poplok tray forming machine is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

EZ Glue Case Max Mechanical Rates:

CS-FB (Flight Bar): 40 cycles per minute

CS-BNB (Bag-in-Box):22 cycles per minute

CS-BD (Belt Drive): 22 cycles per minute

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Poplok tray forming machine is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.