Packaging Systems for Connecticut Companies

Connecticut is situated halfway between New York City and Boston, making it easily a convenient place to stop by. It is also home to expansive farms, archaic seaports, and historic architecture that lets you experience the typical New England. With the abundance of things to do, there’s something for everyone to enjoy. But proximity aside, Connecticut is a beauty and paradise on its own right. Starting from one of its most praised architecture, the state boasts the stunning Glass House in New Canaan with its minimalist structure, geometry, and proportions.

Another thing you should never miss out on Connecticut is its fall season, which is the longest in New England. It’s the perfect time to marvel at the scenic views and colorful trees. One of the top foliage views in this state is the Gillette Castle, a lavish castle that’s seated high above the Connecticut River in East Haddam. And get this, two of the biggest North American casinos turned out to be in Connecticut, not Las Vegas. You can check out Foxwoods Resort Casino in Mashantucket and Mohegan Sun Casino in Uncasville yourself. Before calling it a day, stop by at Abbott’s Lobster in Noank to try their fresh-cooked seafood while taking in the seaside views.

Horizontal Form Fill Seal (HFFS) Machines

Horizontal packaging machines operate by filling products into packs and sealing them. It’s an automated machine that makes use of film to create a sealed pouch or bag in various styles. The pouch can contain both dry and wet products. HFFS packaging machines are used in the final phase of the production line. Most companies today are using horizontal packaging machines as part of their product line-up, mainly because of its several benefits such as:

- It facilitates faster and economical production processes since it encompasses all production stages in one automatic process, making the whole process quicker.

- It’s easy to use, clean, and maintain.

- An HFFS machine provides a flexible packaging solution as it can run on solid, liquid, or dry products with ease.

- It safeguards the products from dust, moisture, and damage while also strictly observing product hygiene by removing human contact for edible items.

- A horizontal type of packaging provides more room for additional texts and graphics.

- This packaging machine offers consistent pharmaceutical packaging solutions, which are essential for exported goods.

How horizontal packaging works in general

Horizontal packaging machines take a film role and run it over a plow to form a bottom of the gusset. This horizontal fill path minimizes the force needed to pull the film through the horizontal bagger. The film is folded flat with two dimensions. Aside from this, the film can also run over succeeding seal stations so it can be heated and cooled. Next, the pouch is pulled open so the machine can fill the products into the film from the top. Most horizontal packages are either 2/3 or 3/4 full.

Lastly, the bag or pouch now filled with products is sealed so it can be ultimately shipped off for consumption. The sealing process normally commences right after the filling, partially to minimize any possible contamination to the products inside the bag, which is especially crucial for food products.

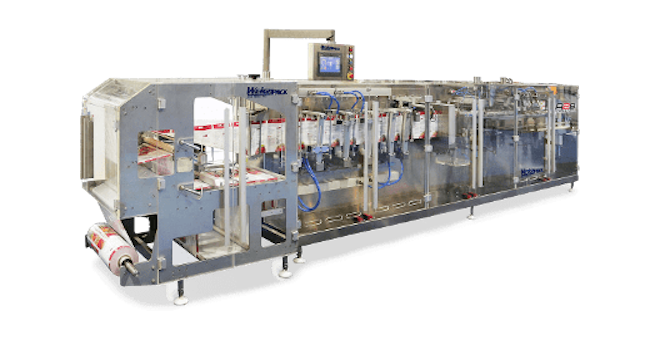

Introducing Paxiom’s R2B 3600 Horizontal Form and Seal

Engineered to provide an automatic forming and sealing process, our R2B 3600 from the WeighPack Systems brand is a high-performance machine that’s highly sought after by many businesses across the world. It’s capable of producing different styles of bags from a laminated film, thus, reducing the material cost significantly as you will no longer need to purchase pre-made bags. Moreover, it is designed for high-speed production rates despite having to perform three packaging stages–forming, filling and sealing.

The R2B 3600 comes with a straight-flow design so operators can visibly supervise the bag forming, filling, and sealing process. This structural design also allows for more convenience when accessing the machine parts. With this horizontal packaging machine, you can create and seal pouches sizing from 3.5 to 7.75 inches wide and 5.5 to 11 inches long. To ensure accurate control over the machine when setting it up and operating it, we have used smart engineering in the form of encoder positioning logic.

In addition to this, both the front and back access panels are made large and removable to provide incredibly easy setup, cleaning, and servicing. For your other specific needs, our horizontal R2B machine comes with additional features including gas flush, vacuum station, hole punch, stand-up bag former, zipper applicator, and shaped bag molder.