Packaging Machines For Colorado Businesses

Colorado is most noted for its vibrant terrain of mountains, red rock formations, prairies, forests, plateaus, desert lands, you name it. This majestic mountain state is part of the western and southwestern United States, with Denver being its capital and also the most populous city in this state. Everyone from art lovers to mountain climbers won’t run out of things to do and places to visit in Colorado. The Breckenridge, for one, is a great place to start if you want to dig deeper into the state’s history. It operates as both a ski resort and mountain town that holds heaps of festivals and arts events all year.

For your hiking adventures, go to Hanging Lake. While the trail itself is just over a mile, it’s also steep and rocky, so be extra careful. Located in southern Colorado is the Great Sand Dunes National Park and Preserve, something that can be easily spotted as it stands in stark contrast to mountains. Another place you should consider visiting is the Red Rocks Park and Amphitheatre that lets you enjoy live music while being surrounded by natural landscapes. This park is strategically centered around the red rock formations, hence the name.

How food filling machines work

Most filler packaging machinery functions with the product loaded into a hopper then pumped using either a vacuum or pneumatics technology or loaded by an auger screw. From there, the product goes through a filler head or nozzle, with portions weighed and measured, into various container types. Automatic food filling machines are equipped with controls and inline equipment to handle the entire filling process, including loading, material handling, dosing, and packaging. Often, the machine can be configured to boost the number of filling heads. Lastly, automatic weigh fillers deliver larger-scale operations and excellent efficiency.

Weigh Filling Packaging Machinery from the Paxiom Group

Marketed under our Primo product line from one of the Paxiom Brands, WeighPack, this family of automatic weigh fillers work to weigh and fill different products. Depending on the mode, you can use our weigh filling solutions to complete 5 to 200 cycles per minute. We manufacture our automated filler machines for solids in 4 various types:

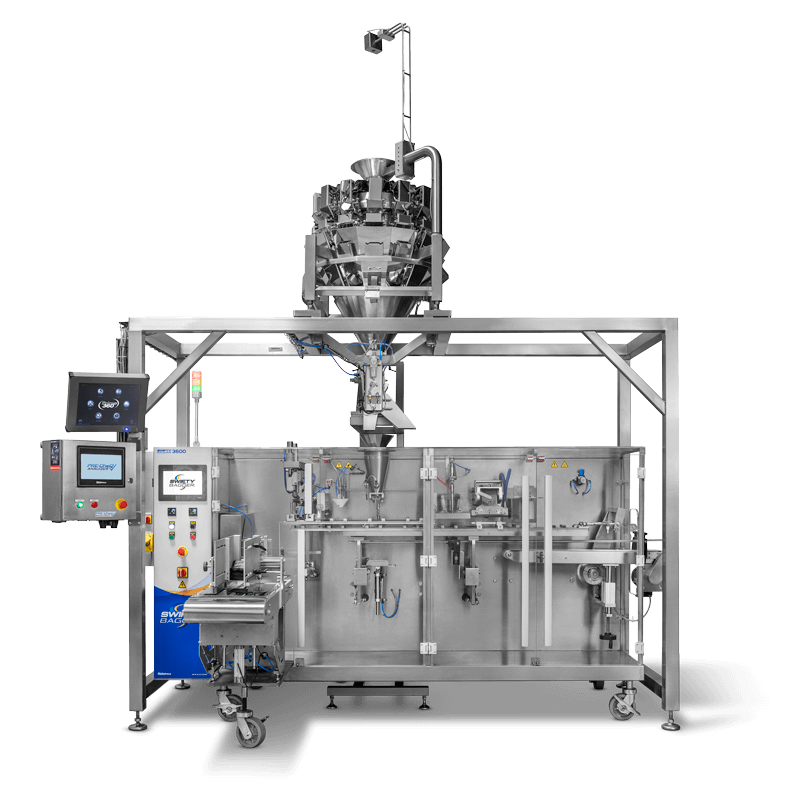

Multihead Weighing

Coming from the family of combination scales, the Primo Multihead Weigher is the most unique among our weigh filler packaging machinery for solids. For starters, it’s available in 4 head configurations (10, 14, 16, and 24) wherein every head is equipped with a load cell. This combination scale is normally, if not all the time, used for bulk filing needs. It features individual vibrator feed pans to provide safer transport of products to the weigh bucket. The PrimoCombi is also engineered with a PC system that functions by determining the buckets that have a near-perfect match. You can integrate our Multihead Weigher Filling machine with an automatic packaging machine or a manual packaging system, whatever your preference is.

Vibratory Net Weigh Filling

Unlike the multi-head weighing machine that came from the PrimoCombi line, this particular filler is manufactured under the PrimoLinear family. It’s an automatic net weigh filler that accurately fills numerous product types into containers, pouches, boxes, jars, and trays. Built for mid-range production rates, this PrimoLinear Vibratory Weigh Filler includes a tool-less hopper and stainless steel construction and eliminates changeover. We have also engineered this packaging machine with removable contact parts and standardized components, thus, lowering the maintenance costs.

Conveyorized Net Weigh Filling

Specifically designed to operate on sticky products, our Conveyorized Net Weigh Fillers works with only the conveyor to transfer the products into the weigh bucket. Like the previous packaging filler machine, this one also comes from the PrimoLinear family. It’s normally used by businesses that directly deal with the filling and packaging of fruits, fresh vegetables, poultry, cheese, meat, and many more. Moreover, apart from sticky products, this conveyorized filing machine also works as little as 5 grams to as much as 50 lbs of bulk and retail weights. You can opt to have a single or twin lane configuration based on the production rates you need.

Bulk Weigh Filling

Our PrimoLinear V and T series consist of bulk weigh filling machines that are specifically built to accommodate large formats of cases and totes. The robust V, which means vibratory, and T for tote filling, are both automatic fillers that can fill up to 50 lbs of products. Thus, it’s a great filling solution for wholesale, food service, and institutional needs of various products including vegetables, fruits, candy, frozen foods, chocolates, ingredients, baked goods, snack foods, and so many more.