VERTICAL CARTONING WITH AUTOMATIC LOADING

The Boxxer™ Kartnr™ V-series automatic carton forming machines are engineered to vertically form a chipboard carton, insert the container and then close the carton. These compact machines can be easily adjusted for multiple products and feature a heavy-duty steel frame, programmable logic controller and a color touch screen.

This versatile machine can handle tucked cartons, pop-up auto-lock cartons or glued cartons and is ideal for loading pharmaceuticals, medicinals, liquids, gels, creams, solids, widgets and health and beauty aids as well as other delicate products.

KARTNR CLOSER – Vertical Carton Closer

Our compact and versatile automatic vertical carton closing machine is engineered to tuck chipboard carton lids with unparalleled precision and efficiency. It provides a unique solution for applications where carton closing needs to be separated from an all-in-one vertical cartoning machine, offering a customized answer to meet your distinct vertical cartoning needs. Its pneumatic minor flap kicker mechanism and lid tucking mechanism ensures precise carton closuring. It can close up to 40 cartons per minute.

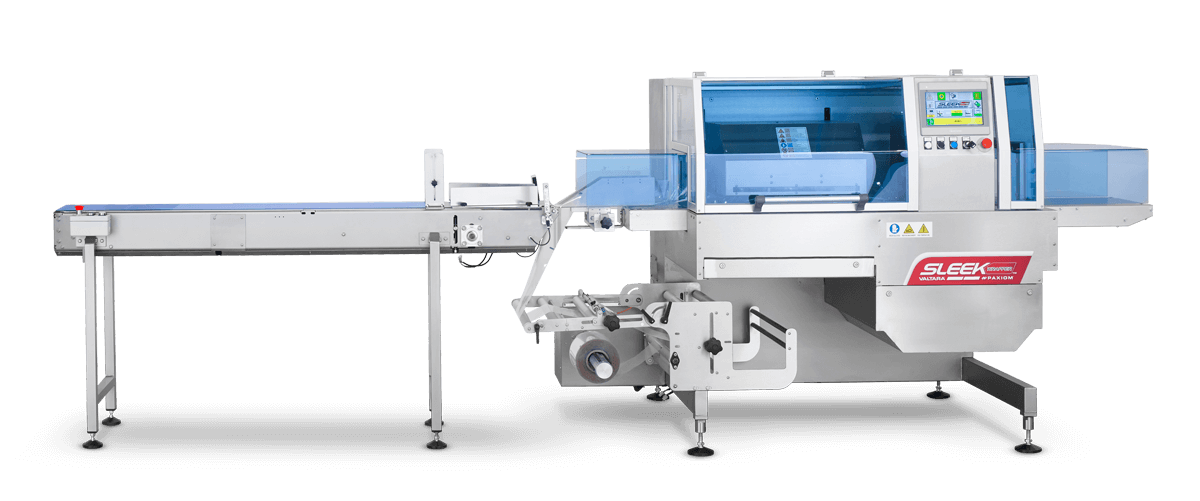

HORIZONTAL CARTONING MACHINE WITH AUTOMATIC INFEED

The Kartnr HCA horizontal cartoning machine with automatic infeed is designed to automatically open, load and close chipboard cartons. The HCA can be configured for either manual or automatic product loading. Commonly used for horizontally inserting bottles, trays and flexible packaging such as blister packs into cartons, this machine is ideally suited for products such as foods, liquids, gels, creams, solids and components.

Along with its convenient product loading station, this reliable machine features a stainless steel frame and compact footprint. An option is available for leaflet dispensing and insertion with detection.

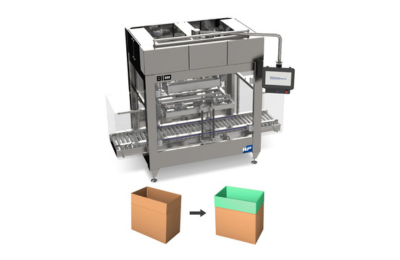

FOLD & TUCK CARTON FORMER WITH LID & INSERT

Engineered for the most complex carton forming applications, the PopLok® tray former with display inserter is commonly used in the pharmaceutical, medical device, beauty, health and consumer electronics industries.

How fold and tuck carton forming works:

The machine pulls a tray blank, one at a time, from the hopper, and pulls it through forming plows and erecting the side and end panels of the tray while folding in the minor flaps. When the tray reaches the bottom of the vertical travel, a set of pneumatically controlled bars fold and lock the rollover flap in place. The finished tray is then indexed in position to load the insert. The insert blank is picked from the hopper, folded and formed before the plunger pushes it down and places it into the formed tray.

Ready to Supercharge Your Production? Contact us for pricing & ROI today.