Milled Flower Packaging

Overview of Milled Flower Products

- Characteristics of Milled Flower Products

- Finely ground cannabis flowers

- Used in pre-rolls, edibles, and cannabis-infused products

- Packaging Requirements

- Maintain consistent particle size and potency

- Preserve quality and prevent contamination

- Key Benefits of Proper Packaging

- Consistency and Quality: Ensures uniform distribution in pre-rolls and edibles

- Potency Preservation: Protects cannabinoids and terpenes, maintaining flavor and effect

- Shelf-Life Extension: Shields from air, moisture, and light, prolonging freshness

- Regulatory Compliance: Meets child-resistant and labeling standards for safety and compliance

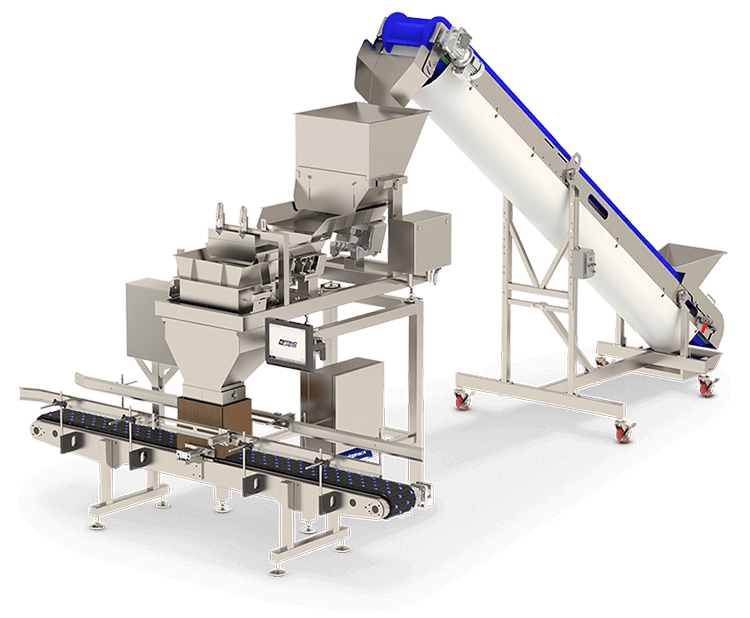

Feeding

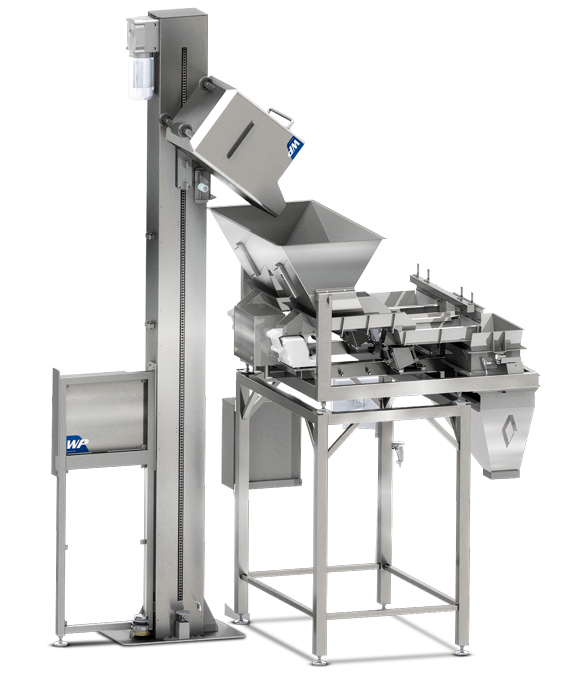

Loader Dumper

Our Loader Dumper is designed to lift and dump milled flower efficiently, ensuring smooth product transfer with minimal manual handling. Its precise operation streamlines the packaging process, maintaining consistency and productivity in high-volume flower packaging.

Features

- Motorized gearbox proximity sensors

- 304 stainless steel frame with easy cleaning

- Security brake control box

- Laser safety scanner

- No pneumatic requirement

Weighing

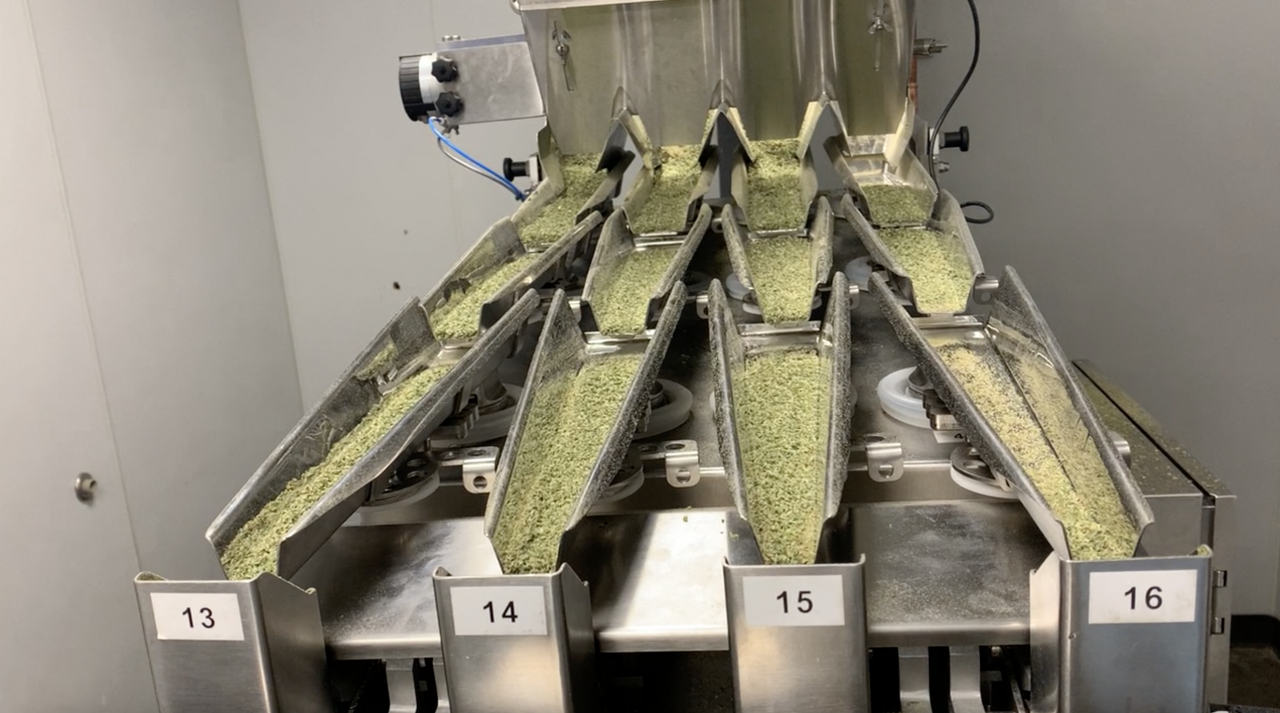

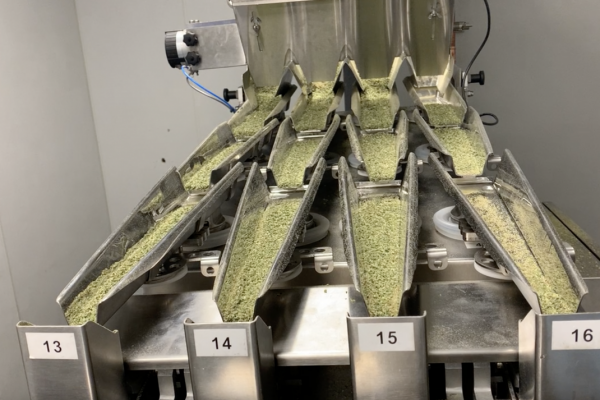

PrimoLinear V-Mini Weigh Filler

PrimoLinear V-Mini accurately fills milled flower into containers, ensuring precise weight control for smaller quantities. Its compact design and advanced technology make it ideal for consistent, high-quality packaging in milled flower operations.

Features

- Digital independent vibrator speed control

- Adjustable electronic filtering

- Multi-speed control

- 304 stainless steel construction (frame and contact parts)

- V-shaped dribble pan

- Compact design

- Tool-less removable buckets and funnel

- PC controls with Windows platform

Jar Filling

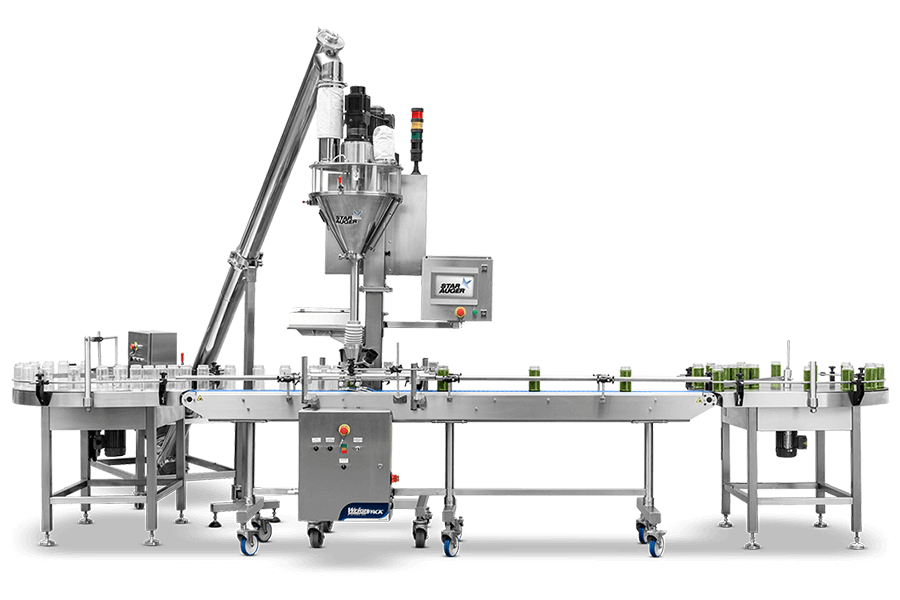

Container Indexer

The Container Indexing Conveyor seamlessly fills milled flower into containers with precision and efficiency. Its automated indexing system ensures accurate filling, reducing waste and optimizing productivity for milled flower packaging lines.

Features

- Compatible with multiple container types (plastic, cardboard, metal, glass)

- Custom-designed for packaging line integration

Capping

KAPR Rotary Chuck Capper

KAPR Rotary Chuck Capper securely applies caps to containers filled with milled flower, ensuring a tight and consistent seal. Its high-speed rotary design enhances efficiency, making it ideal for streamlining the capping process in milled flower packaging operations.

Features

- Stainless steel frame with compact footprint

- Easy-access inspection doors with safety switches

- Integrated inlet/outlet conveyor belts

- Adjustable stainless steel and polyethylene guides

- Dual-speed programming for approach and closing

- Star wheel container transport

- Pressure cap closing unit

- Omron PLC with color touchscreen

- Optional automated cap infeed system

Labeling

Jar Wrap Around LBLR

Our wraparound labeler will automatically label cylindrical bottles, containers, jars and cans with adhesive labels. Features an integrated conveyor, stainless steel frame, color touchscreen and easy-change label supply.

Features

- Stainless steel frame

- Compact footprint

- Split belt conveyor equipped with product guides

- Inlet and outlet conveyor belts with single motorization

- Reel unwinder with reel holder roller

Cartoning

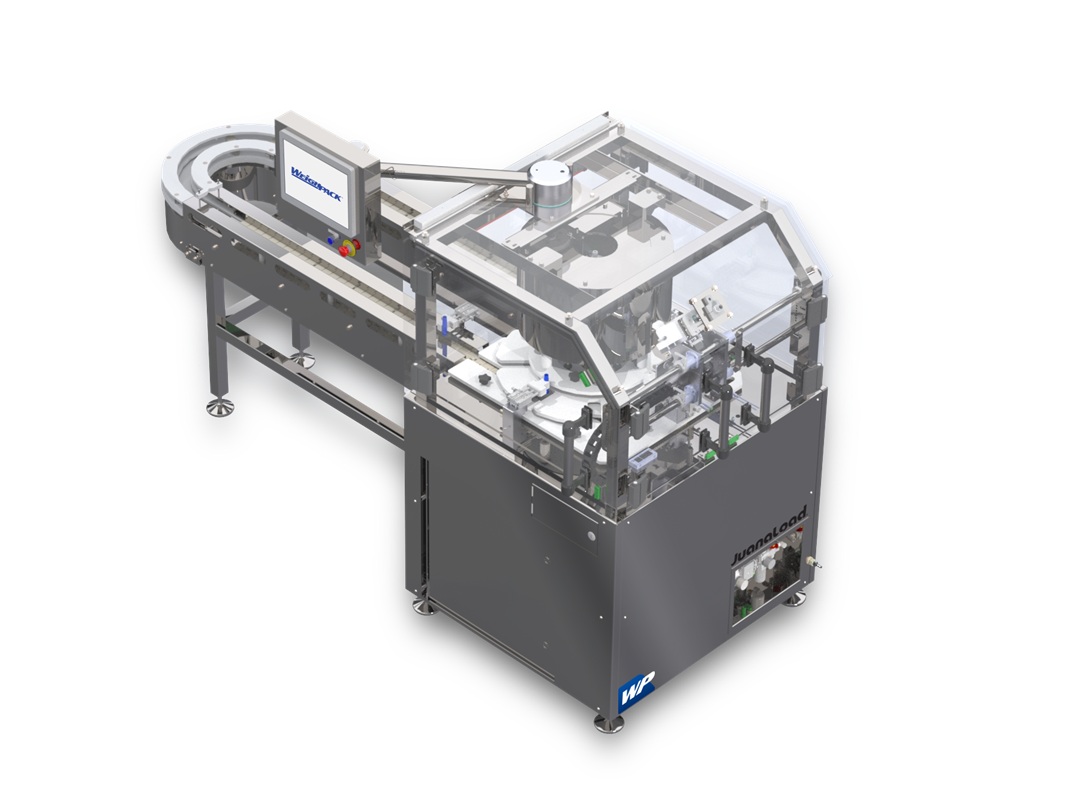

Vertical KARTNR

The Boxxer™ Kartnr™ V-series automatic carton forming machines are engineered to vertically form a chipboard carton, insert the container and then close the carton.

Features

- Quick size change-over

- Configurable for several carton styles/sizes

- Heavy duty painted steel frame

- Rotary star wheel for smooth carton indexing

Inspection

WeightCheQ 0-250

The WeightCheQ 0-250 ensures precise weight verification for milled flower containers, maintaining accuracy and compliance in packaging. Its high-speed operation minimizes errors and waste, ensuring consistency and quality control in production lines.

Features

- Electromagnetic force restoration weigh cell

- Stainless steel/aluminum construction

- Heavy-duty frame with CNC machined foot pads

- High precision load cell

- Modular design with product accumulation drawer

- Food grade belts

- Anti-static Lexan safety guard

- Built-in rejection system

- No changeover parts or compressed air required

- Multi-color warning system with buzzer

Case Packing

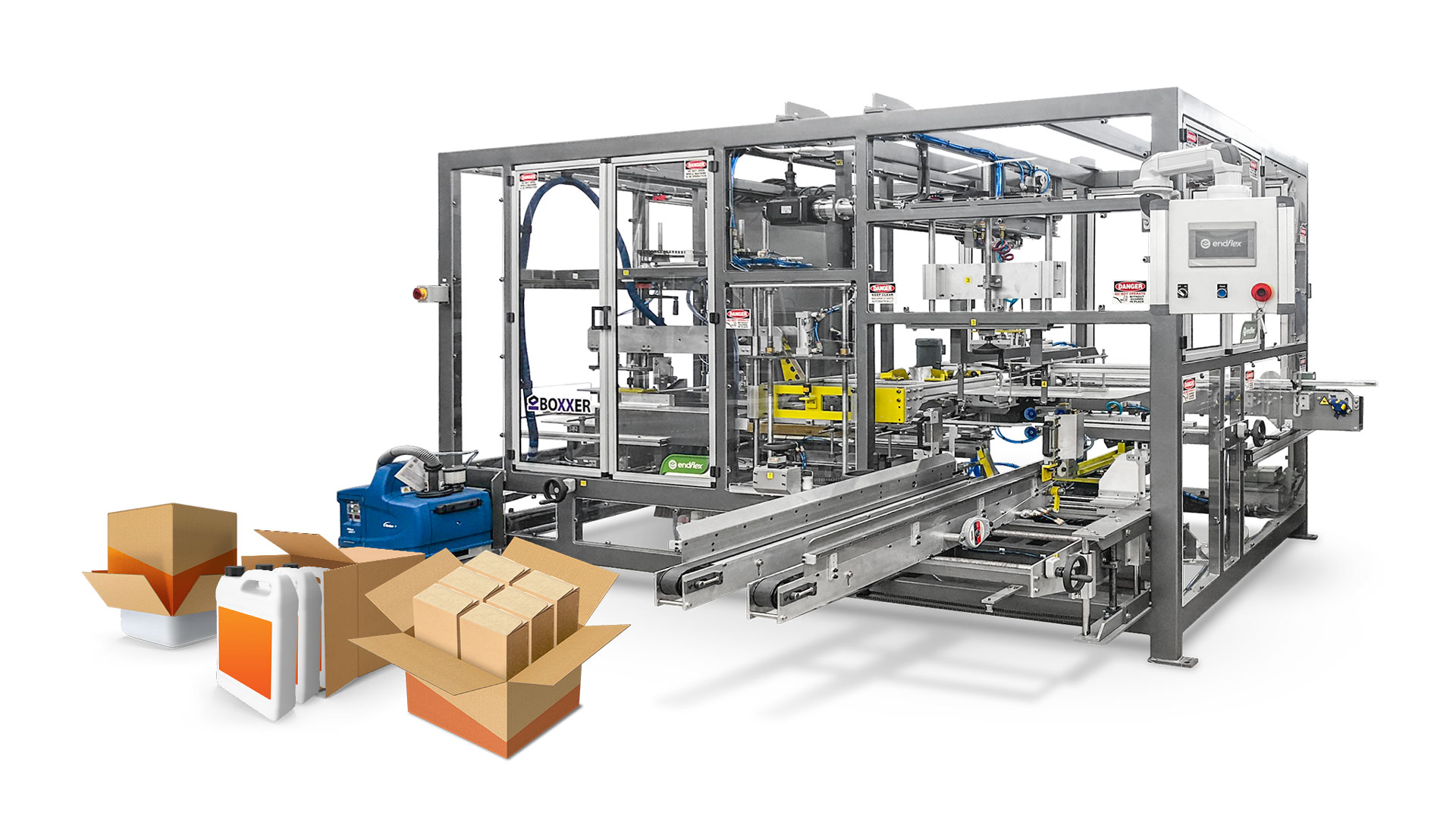

Boxxer All-in-One

The Boxxer All-in-One efficiently erects, loads, and seals cases for milled flower packaging, streamlining the end-of-line process. Its integrated design enhances productivity and ensures secure, professional packaging in high-volume operations.

Features

- Heavy-duty welded tubular steel frame

- Quick size change-over capability

- Venturi vacuum technology

- Omron PLC with color touchscreen

- Product staging and loading area

- Interlocked safety features

- Auto-idler and alarm system

- 24 VDC control voltage

- Comprehensive maintenance interface

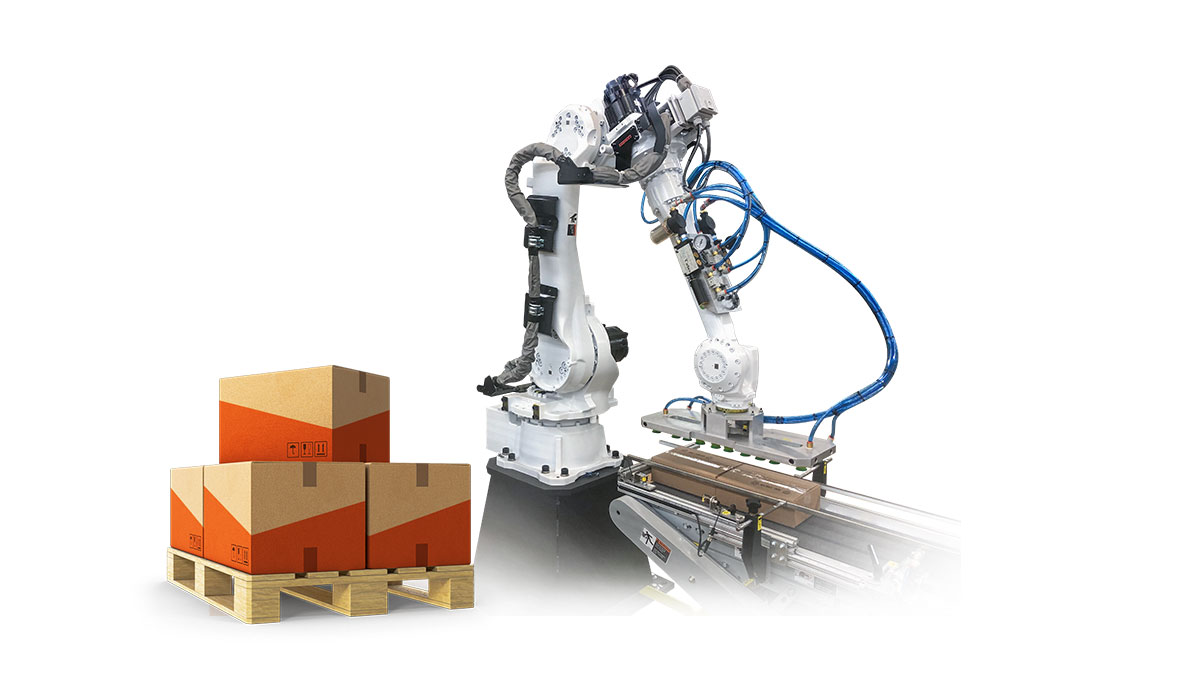

PKR Gantry Robot

The PKR Gantry Robot automates the loading of containers with milled flower, ensuring precise and efficient placement. Its robotic technology enhances speed and accuracy, optimizing packaging lines for high-performance operations.

Features

- Yaskawa GP12 Articulated Robot

- Heavy-duty welded steel construction

- PLC with color touchscreen

- Pick & place unit for gentle handling

- Quick-release change parts

- Safety interlocked guarding

- Venturi vacuum technology

- Optional servo multi-lane diverter

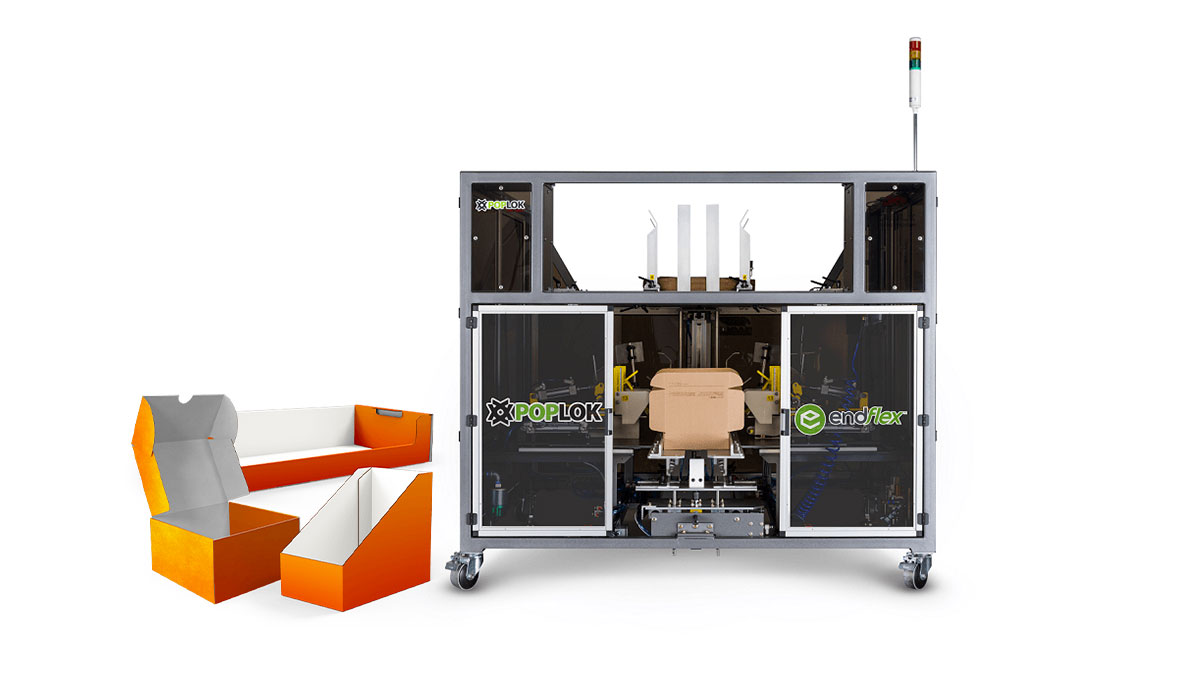

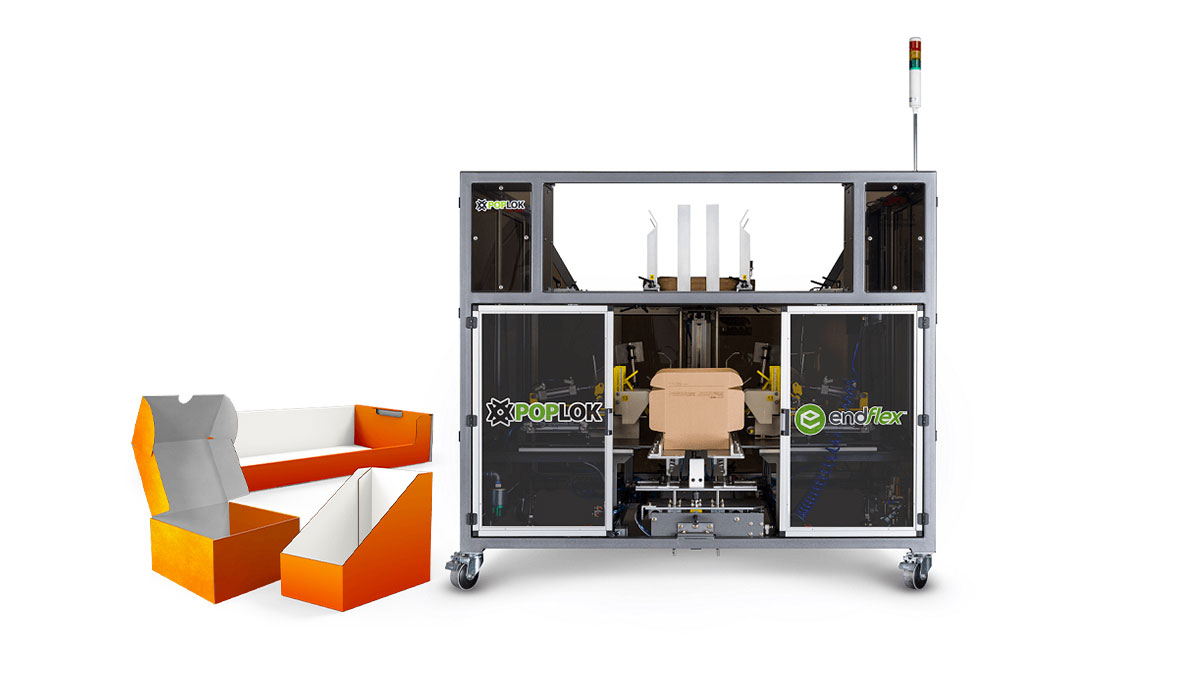

PopLok Tray Former

The PopLok Retail Tray Former quickly and accurately forms retail trays for milled flower products, offering durable and visually appealing packaging solutions. Its high-speed operation ensures efficiency and consistency for streamlined production.

Features

- Multiple tuck/fold configurations available

- Versatile tray size handling

- Tool-less changeover

- Easy-load hopper system

- Heavy-duty frame with safety features

- Venturi vacuum technology

- Omron PLC with touchscreen

- Noise-reducing tray ejection

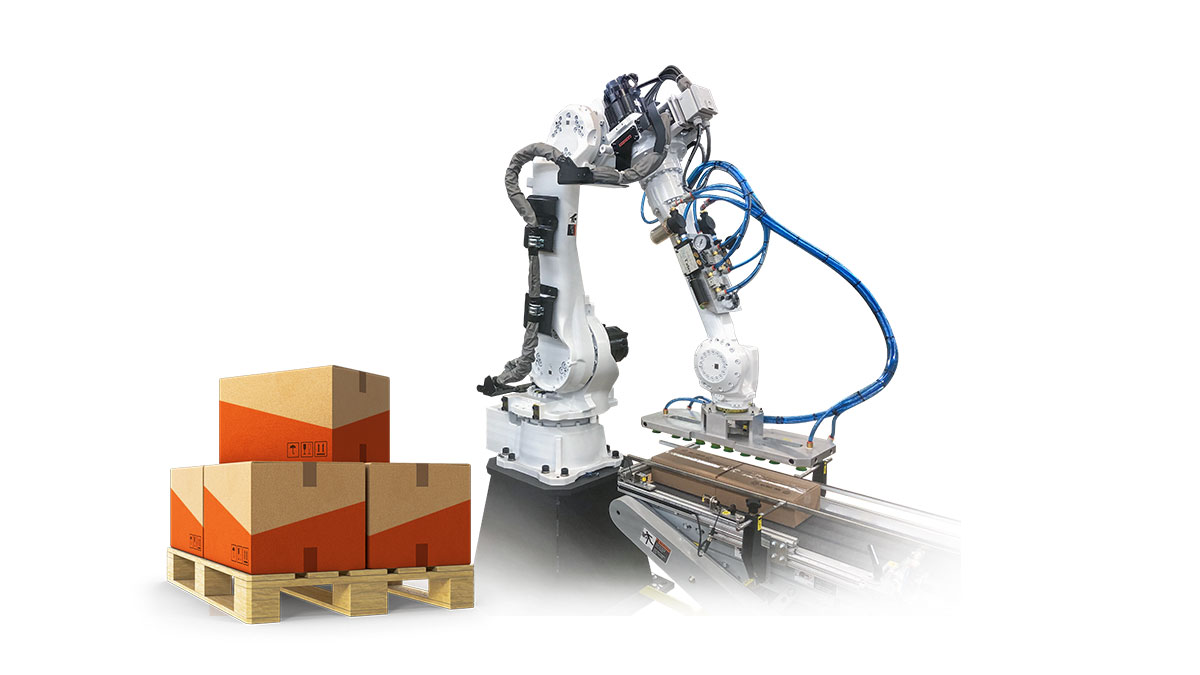

Palletizing

Z.ZAG Cobot

The Z-ZAG Cobot enhances milled flower packaging lines by automating repetitive tasks like packing and palletizing. Its collaborative design ensures safe operation alongside workers, improving efficiency and reducing manual labor.

Features

- 30 kg payload capacity

- 1,700 mm reach

- 0.05 mm repeatability

- Hand-guided teaching capability

- Plug-and-play tool flange

- IP67 rated for sanitary environments

- NSF H1 certified food-grade components

- Power and force limiting safety features

Z.ZAG Robotic Palletizer

The Z-ZAG Robotic Palletizer/Depalletizer efficiently stacks and unstacks pallets of milled flower containers, streamlining end-of-line operations. Its advanced automation boosts productivity while ensuring precision and consistency in pallet handling.

Features

- 80 kg payload capacity

- Extended reach (3,291 mm vertical, 2,061 mm horizontal)

- 5-axis high-performance robot

- Internal cable/airline routing

- Food-grade lubricant options

- Compact base design

- Customizable configuration

BUD/DRY FLOWER PACKAGING

Overview of Bud/Dry Flower Products

- Characteristics of Bud/Dry Flower Products

- Whole or partial cannabis buds

- Used in retail and wholesale formats

- Packaging Requirements

- Maintain product integrity and potency

- Protect against contamination and degradation

- Key Benefits of Proper Packaging

- Consistency and Quality: Ensures product remains intact and potent

- Preservation: Protects cannabinoids and terpenes, maintaining flavor and effect

- Shelf-Life Extension: Shields from air, moisture, and light, prolonging freshness

- Regulatory Compliance: Meets child-resistant and labeling standards for safety and compliance

Feeding

Loader Dumper

The Loader Dumper efficiently lifts and dumps dry flower and bud cannabis, streamlining product transfer into pouch-filling systems. Its precise operation minimizes manual handling and optimizes workflow in pouch packaging lines.

Features

- Motorized gearbox proximity sensors

- 304 stainless steel frame with easy cleaning

- Security brake control box

- Laser safety scanner

- No pneumatic requirement

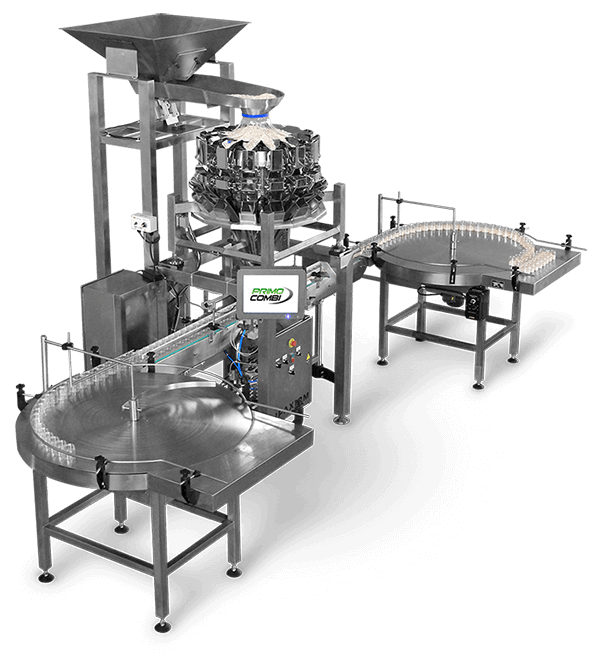

Weighing

PrimoCombi Multihead

The PrimoCombi Multi-Head Weighing Machine precisely measures dry flower and bud cannabis for accurate pouch portioning. Its high-speed, automated weighing system ensures consistency and efficiency in pouch packaging operations.

Features

- Open frame design preventing water penetration

- Single discharge chute system

- Adjustable single post hopper assembly

- Advanced reporting with Crystal Reports™

- Minimum 1 gram dispensing capacity

- Up to 200 packages per minute

- Comprehensive yield and productivity analysis

Pouch Filling

Swifty Bagger 3600 & 1200

The Swifty Bagger 3600/1200 efficiently fills pouches with dry flower and bud cannabis, providing accurate and consistent packaging. Its user-friendly design and high-speed operation streamline the production of various pouch sizes.

Features

- Production rate: up to 2,000 bags per hour

- Multiple bag type compatibility

- Servo-driven precision filling

- Compact footprint

- Color touchscreen interface

- Flexible system integration

- Stainless steel construction

- Enhanced safety features

Swifty Bagger Mini

The Swifty Bagger Mini is perfect for compactly and accurately filling pouches with dry flower and bud cannabis. Its space-saving design and efficient operation make it ideal for small-scale pouch packaging needs.

Features

- Omron PLC system

- PID temperature control

- Color touchscreen interface

- SMC vacuum generator

- Quick bag loading station

- No bag-no fill sensor

- 304 stainless steel frame

Swifty Bagger Junior

The Swifty Junior efficiently fills pouches with dry flower and bud cannabis, ensuring accurate and consistent packaging. Its compact design is ideal for smaller operations looking to enhance productivity in pouch packaging.

Features

- Omron PLC system

- PID temperature control

- Color touchscreen interface

- SMC vacuum generator

- Quick bag loading station

- No bag-no fill sensor

- 304 stainless steel frame

Inspection

WeightCheQ 0-250

The WeightCheQ 0-250 ensures precise weight verification for pouches of dry flower and bud cannabis. Its high-accuracy system supports quality control and compliance in pouch packaging operations.

Features

- Up to 300 pieces per minute capacity

- 0.01 gram precision

- Weight range: 1-250 grams

- Compact design

- User-friendly touchscreen

- ERP/MRP system integration

- Durable stainless steel construction

Case Forming & Packing

Boxxer T

The Boxxer T-series case former automatically erects corrugated RSC or HSC cases and seals them with glue or tape. Our series of case formers include models for low, mid and high-speed production rates, offering reliable and user-friendly operation at speeds up to 35 boxes per minute.

Features

- Boxxer™ T 12- Up to 12 cycles per minute

- Boxxer™ T 18– Up to 18 cycles per minute

- Boxxer™ T XL– Up to 8 cycles per minute

PKR Delta Robotic Top Loader

The PKR Delta Robotic Top Loader precisely places pouches of dry flower and bud cannabis into cases or trays. Its advanced robotic system ensures efficient and accurate handling, optimizing productivity in pouch packaging lines.

Features

- Up to 50 single picks per minute

- Up to 80 dual picks per minute

- Multi-package type handling

- Vacuum/mechanical pickup options

- Space-efficient design

- Flexible case/tray configuration

- Production line integration

PopLok Tray Former

The PopLok Retail Tray Former creates sturdy retail trays for pouches of dry flower and bud cannabis. Its efficient operation enhances presentation and organization, supporting streamlined pouch packaging workflows.

Features

- Multiple tuck/fold configurations

- Versatile tray size handling

- Tool-less changeover system

- 100% recyclable production

- Easy-load hopper system

- Heavy-duty safety frame

- Venturi vacuum technology

- Omron PLC with touchscreen

- Noise-reducing ejection

- Online operation manual

Palletizing

The Z.ZAG Cobot automates repetitive tasks like packing and palletizing pouches of dry flower and bud cannabis with precision. Its collaborative design ensures safe integration with workers, improving efficiency in pouch packaging operations.

Features

- 30 kg payload capacity

- 1,700 mm reach

- 0.05 mm repeatability

- 6-axis collaborative design

- Hand-guided programming

- Quick-connect tooling

- IP67 rated construction

- NSF H1 certified components

- Enhanced safety features

The Z.ZAG Robotic Palletizer/Depalletizer automates the stacking and unstacking of pallets for pouches of dry flower and bud cannabis. Its advanced robotics enhance efficiency and precision, streamlining end-of-line pouch packaging operations.

Features

- 80 kg payload capacity

- 5-axis precision control

- Extended reach capabilities

- Internal cable routing

- Food-grade components

- Space-efficient design

- Customizable configuration

- Comprehensive automation

Ready to Supercharge Your Production? Contact us for pricing & ROI today.