Primary Packaging Solutions for Gummies & Edibles

Packaging gummies and edibles requires care to keep their texture and flavor intact. Whether using jars or child-resistant pouches, proper packaging ensures that the product stays fresh and safe. Accurate weighing, counting, and sealing are essential to meet safety standards and provide customers with a reliable product.

Benefits of Proper Primary Packaging for Gummies & Edibles

- Maintains Product Quality: Keeps gummies and edibles fresh, retaining their texture and flavor.

- Accurate Portioning: Ensures consistent product amounts with no underfilling or overfilling.

- Safety Compliance: Child-resistant packaging meets legal requirements and protects consumers.

- Longer Shelf Life: Prevents air and moisture from spoiling the product.

- Improves Brand Image: Reliable, attractive packaging boosts customer satisfaction and brand appeal.

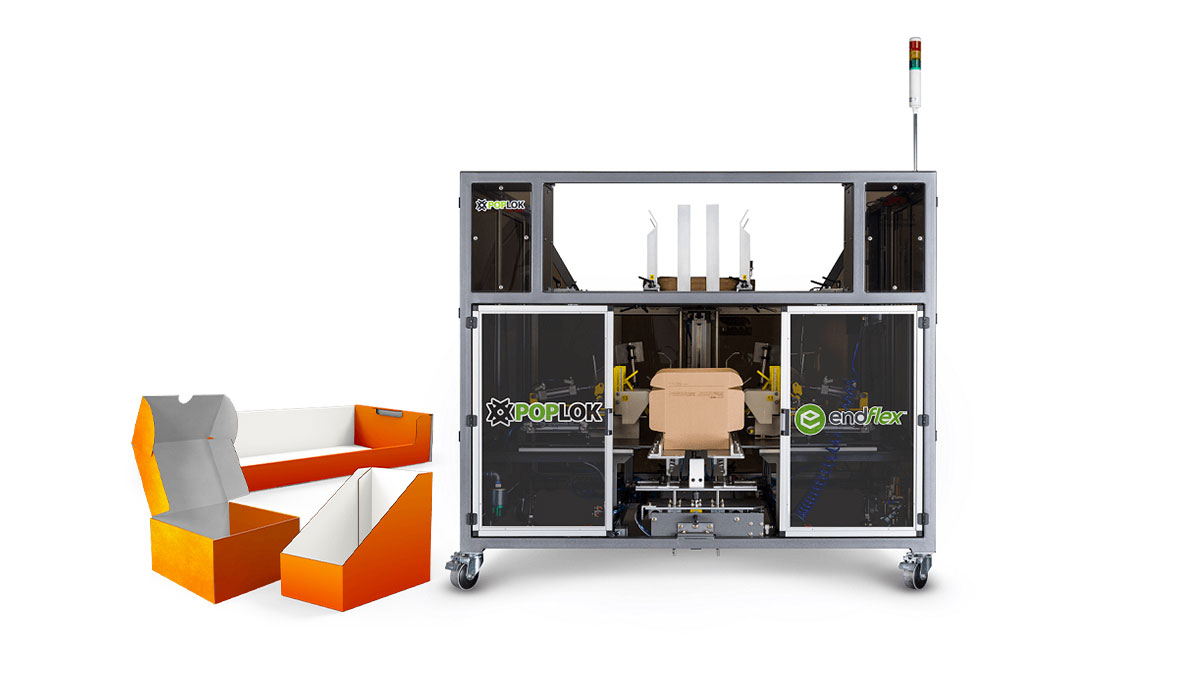

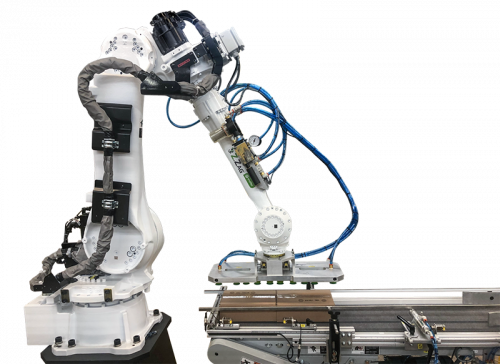

Secondary & End of Line Packaging Solutions for Gummies & Edibles

Secondary packaging is key to protecting gummies and edibles after they’re individually packaged. This packaging ensures products stay secure during shipping and handling while boosting their presentation. From case packing to palletizing, it keeps gummies and edibles safe and ready for distribution.

Benefits of Proper Secondary Packaging for Gummies & Edibles

- Product Protection: Adds extra safety to prevent damage during shipping and storage.

- Regulatory Compliance: Meets labeling, tamper-evidence, and child-safety regulations.

- Efficient Handling: Simplifies bulk transport and reduces the risk of damage.

- Enhances Presentation: Improves product presentation on store shelves.

Auxiliary Packaging Solutions for Gummies & Edibles

Auxiliary packaging machines play a vital role in ensuring that gummies and edibles are perfectly packaged to maintain their texture and flavor. Utilizing equipment such as check weighing systems, labeling machines, capping machines, unscrambling equipment, conveying machines, and vision inspection tools ensures that the packaging process is both efficient and precise.

Benefits of Auxiliary Packaging Machines for Gummies & Edibles

- Maintains Product Quality: Check weighing systems ensure accurate weight of each package, keeping gummies and edibles consistent and fresh.

- Accurate Portioning: Conveying machines seamlessly transport products through the packaging process, reducing the risk of underfilling or overfilling.

- Safety Compliance: Vision inspection tools detect any packaging defects, ensuring that child-resistant pouches meet legal standards and protect consumers.

- Longer Shelf Life: Proper sealing and packaging prevent air and moisture from spoiling the product, thanks to precise machinery, including capping machines.

- Improves Brand Image: Reliable and attractive packaging, achieved through the use of advanced auxiliary machines like labeling machines and unscrambling equipment, boosts customer satisfaction and brand appeal.

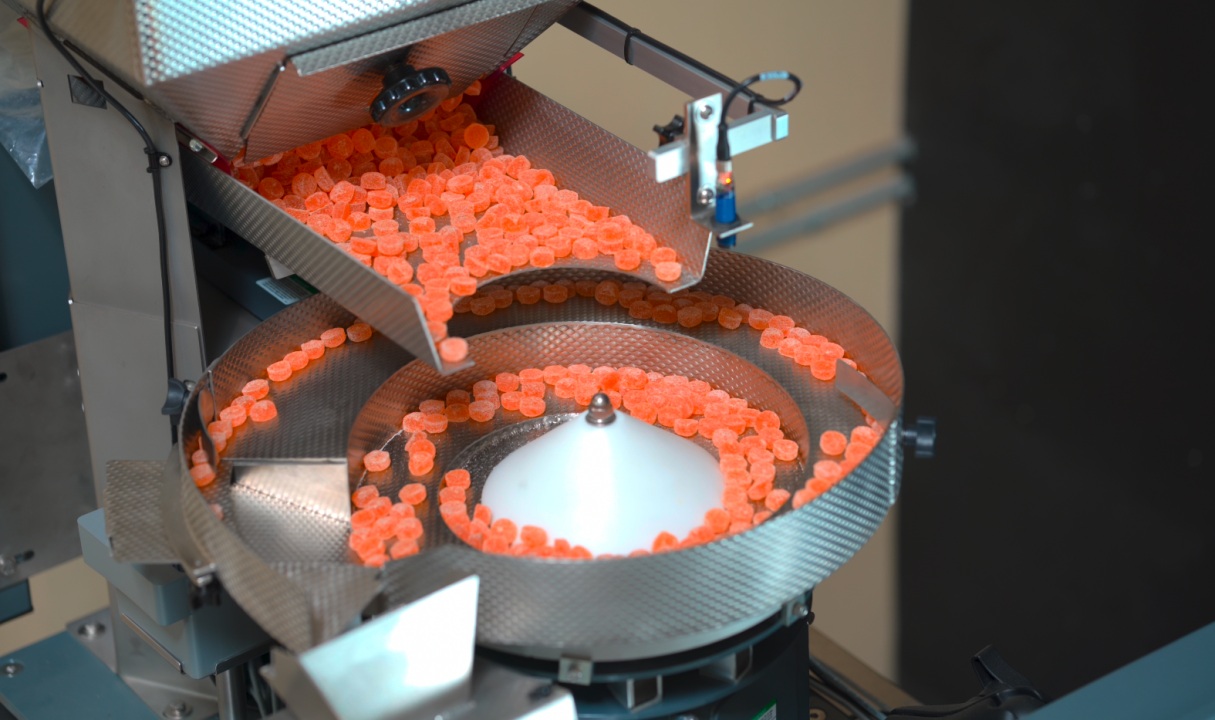

Weighing & Counting

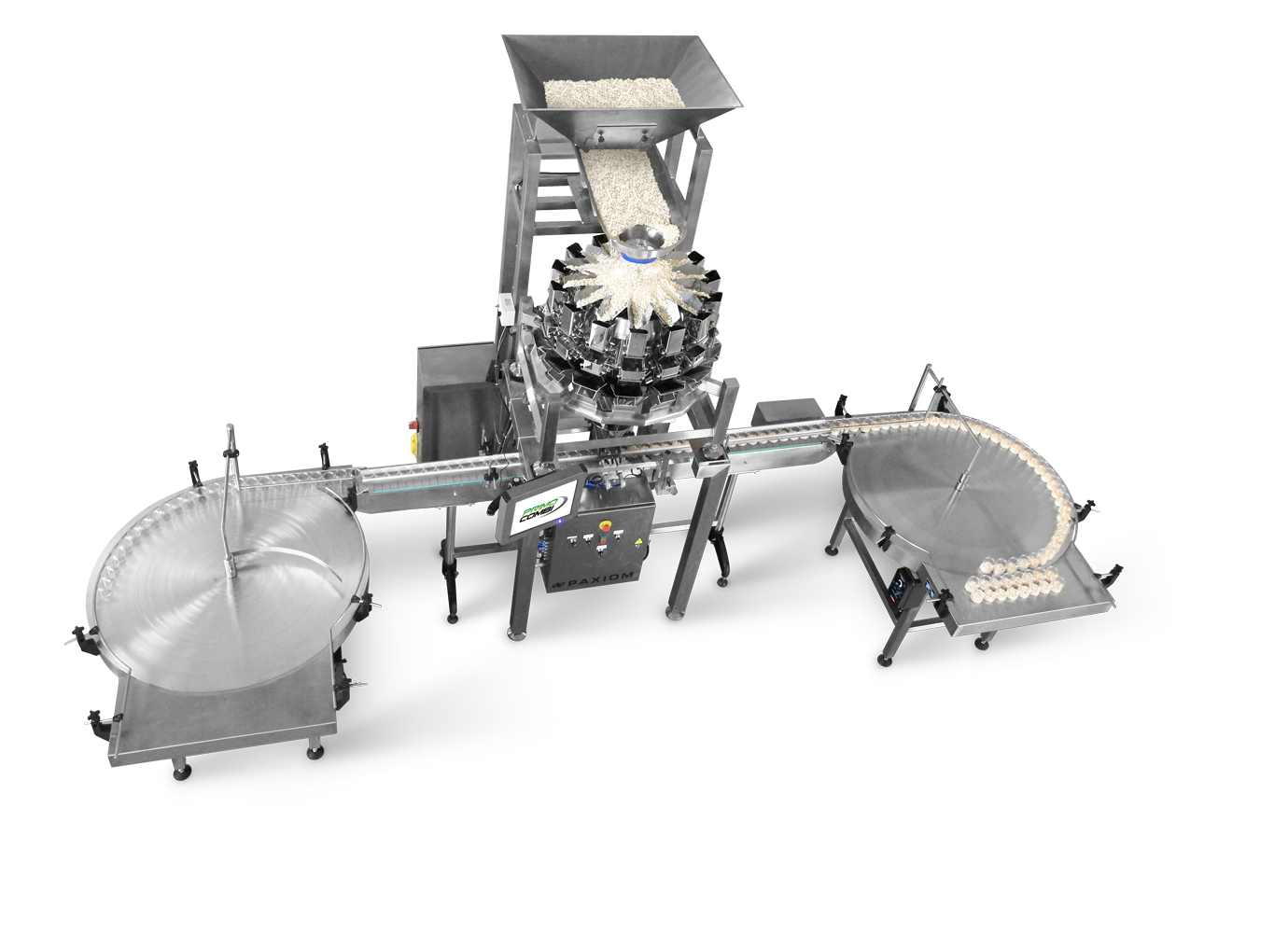

PrimoCombi

The PrimoCombi is designed for precise weighing and portioning of cannabis edibles and gummies. Its high-speed, automated system ensures accurate and consistent product weight, optimizing packaging efficiency and quality control in cannabis edible production lines.

Features

- Available in 10, 14, 16, and 24-head configurations.

- Each lane has its own load cell for precise weighing.

- Vibratory feeder pans transport bulk product to weigh buckets.

- Weigh buckets measure and weigh products for accurate packaging.

- PC logic system calculates optimal weight combinations.

- Simultaneous dispensing into packaging machine or manual station.

- Seamlessly integrates with SwiftyBagger 3600 for premade pouch filling.

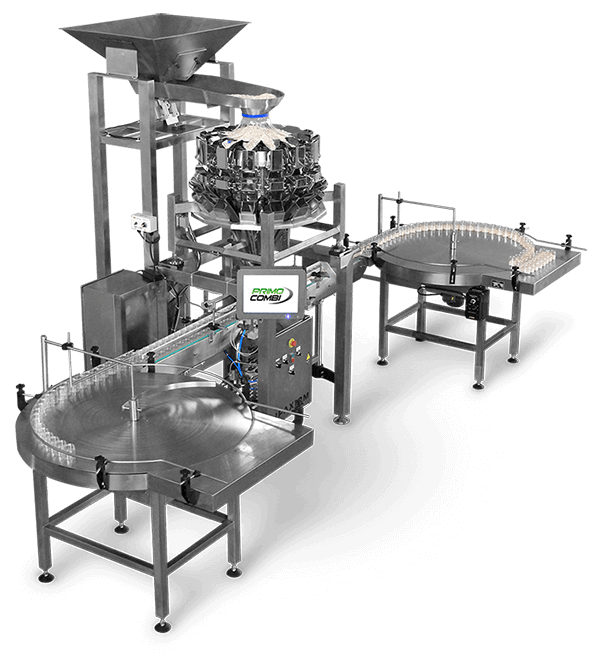

PrimoCount

The PrimoCount is designed for accurately counting cannabis edibles and gummies. Its advanced optical technology ensures precise, high-speed counting, making it ideal for efficiently packaging edibles in various forms, ensuring consistency and accuracy in cannabis product packaging.

Features

- Uses advanced optical sensors for precise product counting.

- Bowl feeder directs products into the counting system.

- Capable of high-speed counting to meet production demands.

- Suitable for various product types, including gummies and small items.

- Easily integrates into existing packaging lines.

Pouch Bagging (Child-Resistant)

SwiftyBagger 3600/1200

The SwiftyBagger 3600/1200 efficiently fills child-resistant pouches with cannabis edibles and gummies, ensuring precise portioning and secure sealing. Its high-speed operation and user-friendly design make it ideal for large-scale production of cannabis edibles in compliant, child-resistant packaging.

Features

- Fills up to 2,400 bags per hour (2,700 with higher-speed model).

- Straight-line design provides full visibility for easy operation and maintenance.

- Automatic zipper opening device ensures consistent bag opening.

- Bag shaker levels product for even filling.

- Seamlessly moves bags from filling to sealing.

- Handles DOY pack, SUP, SURP, pillow, gusseted, quad, and carry handle pouches.

- Includes no bag-no fill sensor, funnel clog sensor, and mechanical bag opening device.

- Features vacuum mechanism for efficient bag loading.

- Durable and easy-to-clean structure.

SwiftyBagger Mini

The SwiftyBagger Mini is a compact pouch filling machine designed for cannabis edibles and gummies, offering child-resistant packaging solutions in a space-saving design. It ensures accurate filling and quick sealing, perfect for small to medium-sized cannabis edible operations requiring efficient and compliant packaging.

Features

- Compact design, occupying just 10 square feet of floor space, ideal for smaller production environments.

- Automatic operation opens, fills, and seals premade stand-up pouches.

- Compatible with auxiliary filling machines like PrimoCombi, PrimoLinear, and Star Auger.

- Omron PLC system ensures smooth operation.

- User-friendly interface for easy operation and adjustments.

- No Bag-No Fill sensor prevents wasted product.

- 304 stainless steel frame for durability.

- Quick bag loading station for efficient operation.

SwiftyBagger Junior

The SwiftyBagger Junior provides reliable, high-speed pouch filling for cannabis edibles and gummies, ensuring child-resistant packaging. Its compact design and precise operation make it an ideal choice for cannabis businesses looking to streamline their packaging process while meeting compliance standards for edibles and gummies.

Features

- Compact design occupying just 10 square feet, ideal for smaller production environments.

- Automatic operation opens, fills, and seals premade stand-up pouches (SUP, SURP, DOY) in one seamless process.

- Processes up to 900 bags per hour.

- Omron PLC system for smooth, consistent operation.

- Intuitive color touchscreen interface for easy use and adjustments.

- No Bag-No Fill sensor prevents product waste by halting if no bag is detected.

- Durable 304 stainless steel frame.

- Quick bag loading station for efficiency.

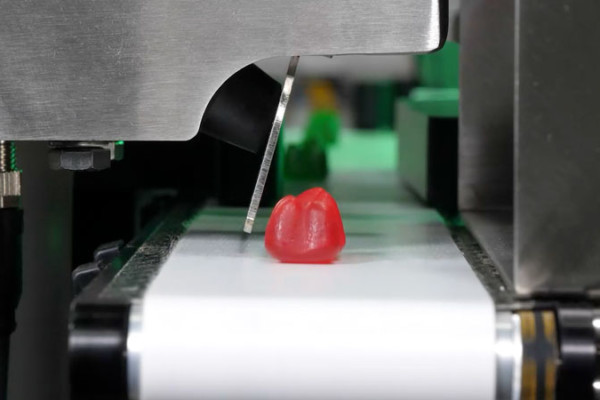

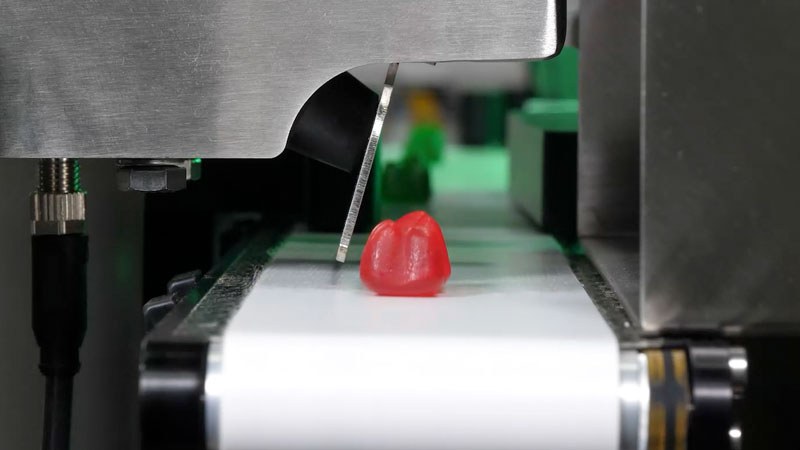

Flow Wrapping

SleekWrapper 40

Servo-driven flow wrapper for cannabis edibles and gummies, designed for small to medium-sized production lines. Ensures precise, airtight packaging at speeds of up to 120 packages per minute with a 15.5” max web width.

Features

- Full servo drive (4 motors)

- Stainless steel frame

- Belt-driven infeed with snap-in pushers

- Cantilevered film holder

- Touchscreen HMI with Mitsubishi PLC

- Pre-programmable (100 recipes)

- Rotary seal jaws with jam detection

- Optional features: No Product/No Bag, No Gap/No Seal for misplaced products

SleekWrapper 45

Servo-driven flow wrapping machine for cannabis edibles and gummies, engineered for high-speed automated packaging. Produces up to 160 packages per minute with an 18” max web width, ensuring efficient, tamper-evident sealing.

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt-driven infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touchscreen HMI with Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Automatic open/close rotary fin wheel assembly

- Rotary seal jaws with jam detection logic

- Optional features: No Product/No Bag, No Gap/No Seal for misplaced products

SleekWrapper HSA

High-speed flow wrapper with a chicane product aligner, ideal for gummies, chocolates, and infused edibles. Wraps up to 300 packages per minute, ensuring precision, freshness, and regulatory compliance.

Features

- Advanced full servo motor and driver control system

- Large color touchscreen with PLC controls

- Photoelectric automatic detection and servo dosing system

- Automatic acceleration/deceleration with accurate positioning

- 304 stainless steel sheet metal exterior

- Integrated system design

- Optional second film roll support with automatic splicing

Jar Packaging

Container Indexer

The Container Indexer automates the precise filling of jars with cannabis edibles and gummies, ensuring accuracy in portioning. Its efficient design optimizes productivity and consistency, ideal for high-volume cannabis packaging operations.

Features

- Automatically fills rigid plastic, cardboard, metal, or glass containers.

- Suitable for filling hardware, candy, chocolates, nuts, snacks, pharmaceuticals, powders, tablets, gel caps, gummies, cannabis, and medicinals.

- Tailored to meet specific container filling requirements.

- Compatible with a wide range of container materials and shapes.

SpinDexer

The SpinDexer rotary indexing conveyor and container filler is engineered for high-speed applications and is perfect for filling narrow containers. Commonly used to fill jars, cans, tubes and containers with products ranging from CBD and infused edibles to THC capsules.

Features

- Variable speed infeed / discharge conveyor

- Single station fill spout

- Servo drive

- No container—no fill sensor

- Totally enclosed, Lexan safety covers• Safety switches & E-stop

Ready to Supercharge Your Production? Contact us for pricing & ROI today.