In today’s competitive packaging industry, efficiency is more important than ever. The global packaging automation market was estimated at $69.18 billion in 2022 and is expected to reach $145.93 billion by 2032—yet, businesses are still under constant pressure to reduce costs, speed up production, and maintain precision.

Automated pick and place robots are revolutionizing the way companies handle packaging tasks by automating repetitive actions and seamlessly integrating into existing production lines. As you’ll learn, these systems not only boost speed and accuracy, but also reduce labor costs and human error—helping businesses achieve maximum efficiency.

What are Pick and Place Systems?

Pick and place systems automate repetitive tasks in packaging by using robotic arms to move items from one location to another.

Key Features:

- Robotic Arms: Mimic human movements but with greater speed and precision.

- Sensors & Vision Technology: Enable robots to recognize and adjust to different product sizes, shapes, and orientations.

- AI Algorithms: Help robots adapt to dynamic production environments, reducing errors and increasing consistency.

How They Work:

- Product Detection: Using vision systems, the robot identifies the position, size, and shape of products.

- Picking: The robotic arm picks up the product from a conveyor or designated spot.

- Placement: The robot accurately places the product into packaging, boxes, or onto pallets.

Benefits:

- Speed & Accuracy: Operates continuously, minimizing human error.

- Versatility: Handles a wide range of product types, from delicate to irregularly shaped items.

- Cost-Effective: Reduces labor costs and improves overall workflow efficiency.

According to an article from Food Manufacture, in a manual picking operation by Nestlé, approximately 200 cases were picked per man-hour, while a robotic picker system handled 900 cases per man-hour, representing a 77.7% increase in efficiency.

How Pick and Place Systems Maximize Packaging Efficiency

Automated pick and place systems are a game-changer for packaging operations. These features contribute significantly to boosting packaging efficiency:

1 ) Seamless Integration with Packaging Equipment

One of the greatest advantages of pick and place systems is their ability to integrate smoothly into existing production lines without disrupting workflows. Whether your operation involves conveyors, filling machines, or labeling equipment, pick and place robots can be programmed to synchronize with these components, creating a continuous, efficient flow. This means minimal downtime during installation and transition periods.

These systems are designed with user-friendly interfaces and advanced compatibility, allowing for seamless communication between different packaging stages. As a result, they can easily handle upstream and downstream processes, such as product sorting, packing, and labeling. The integration ensures higher throughput and reduced bottlenecks, enabling companies to meet their production goals more efficiently.

2 ) Adaptability and Flexibility

Modern pick and place systems are incredibly versatile, capable of adapting to various product sizes, shapes, and packaging formats. Whether your operation deals with small, delicate items or larger, bulkier products, these robots can be easily reprogrammed to accommodate changes in product types. This adaptability allows businesses to scale operations and respond quickly to market demands.

Robots equipped with vision systems and advanced sensors can adjust in real-time, making it possible to handle different packaging configurations or custom product requests with minimal manual intervention. This flexibility is especially beneficial in industries that frequently change their product lines or packaging styles, allowing for smoother transitions and more efficient use of resources.

A Closer Look at Paxiom’s Automated Pick and Place Solutions

At Paxiom, our focus is on delivering automated solutions that maximize packaging efficiency and streamline production processes. Our pick and place systems are designed for a variety of packaging applications, offering the speed, precision, and flexibility needed to meet the demands of modern packaging lines.

Let’s take a closer look at three of our most popular systems:

PKR Gantry Robot

The PKR Gantry Robot is ideal for large-scale operations requiring high-speed precision. This robotic loader excels at handling various products like jars, cans, bottles, and clamshells. Its gantry design allows it to work over a wide area, ensuring that products are consistently placed with precision. By integrating this into your packaging line, you can significantly improve your throughput while maintaining accuracy and reducing manual labor.

PKR Delta Robot

Our PKR Delta Robot is built for speed and agility, making it perfect for lightweight products in high-speed operations. Whether sorting or grouping bags, pouches, or flexible packages, this top-loader robot ensures that even the fastest production lines maintain precision and consistency. This makes it especially effective for industries with high-volume packaging needs, allowing for quicker, more efficient handling.

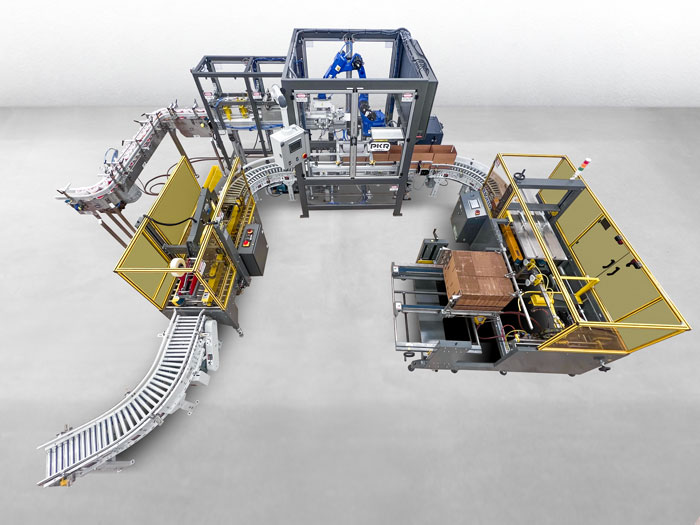

PKR Robot

The PKR Robot offers unmatched versatility, excelling in complex tasks like palletizing and case packing. Its articulated arm can maneuver in tight spaces, handling various product sizes and shapes with ease. Whether you’re working with delicate or bulky items, the PKR Robot brings flexibility to any packaging line, ensuring smooth operations and optimized performance.

Maximizing Your Packaging Efficiency with Paxiom

Automated pick and place systems have transformed packaging operations by increasing speed, accuracy, and flexibility. From seamlessly integrating with existing production lines to adapting to various product types and packaging formats, these systems are essential for companies looking to stay competitive in today’s market.

At Paxiom, we specialize in delivering solutions that meet your specific needs, ensuring your packaging process is faster, smarter, and more cost-effective. Contact us today to learn how our advanced pick and place systems can help you maximize efficiency and stay ahead of the competition.