Are you having problems filling rigid containers with your products? Easy – Paxiom’s container filling solutions have you covered. With our custom-designed solutions, you can weigh fill plastic, metal, or cardboard containers with powders, nuts, snacks, candy, tablets, chocolates, pharmaceuticals, and so much more.

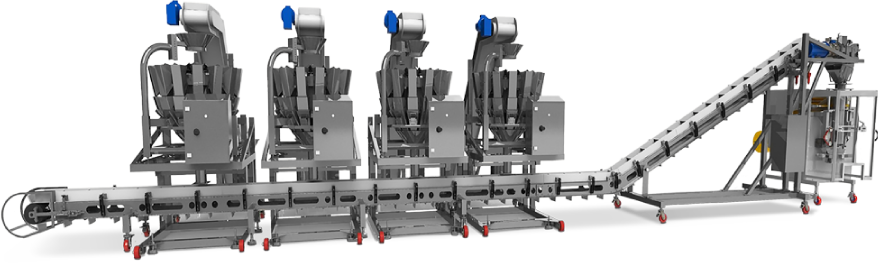

PrimoCombi for high-performance packaging applications

Available in three models, our PrimoCombi automated packaging machine is engineered for projects that require increased production rates and tight accuracy tolerances. To manufacture a food-safe machine that needs less operator involvement, while offering serviceability, reliability, speed, and accuracy, we made sure that our PrimoCombi is built with leading-edge mechanics and software.

This uncluttered machine is constructed as such to eliminate any possibility of bacteria breeding in a nook or cranny. With its innovative stainless steel open frame, maintenance personnel can have shorter wash-down time. Designed with operator convenience in mind, the PrimoCombi is built with a tool-less adjustable and rotating hopper for a simple product change over and cleaning and better product flow.

Another leading-edge mechanical feature of the PrimoCombi is its smarter electronics. This electrical system substantially reduces wiring and components. In doing so, the container filling machine will be much easy to service, not to mention more economical to maintain. Its control panel is also remotely mounted and can be set up away from the scale. This way, it’s easy to access the PrimoCombi without the risk of damaging the control panel when cleaning.

As for its leading-edge software features, our multi-head weigher is run by the 360 Operating Software that streamlines combination weighing. With Crystal Reports, you can easily customize your reports in whatever format to obtain any necessary information.

SpinDexer for high-speed container filling

This automatic packaging machinery designed to fill a wide variety of products into rigid containers. The SpinDexer rotary indexing conveyor comes in many models and is engineered for high-speed applications and filling narrow containers. It’s perfect for snack foods, coffee, confections, spices, powders, pharmaceuticals, and nutraceuticals. With the SpinDexer, you can fill rigid containers with your desired products and even those irregularly shaped at high speeds.

Constructed with a stainless steel frame, our high-speed container filling machine has servo drives to ensure total control of the container. Additionally, acceleration, deceleration, and braking are also easily programmed as per container characteristics. With PLC-based controls, the SpinDexer allows the operator to control all functions through the color touch screen. This also helps ensure a synchronized timing of moving parts.

Another remarkable feature of the SpinDexer is its sensors that are found in critical areas to ensure no-container, no-fill, upstream bottle stop, and available reject station. These sensing devices are also there to provide increased throughput as a result of increased efficiency. The SpinDexer also allows easy integration with any auxiliary filling machine including the Star Auger, PrimoCombi, and PrimoLinear filling machines.

Available in three models:

1. SpinDexer 1800 Rotary Indexing Conveyor

2. SpinDexer Rotary Indexing Conveyor with Travelling Funnels

3.SpinDexer XL Rotary Indexing Conveyor with Travelling Funnels

PrimoLinear for bulk weigh filling cases

Automatically weigh fill your corrugated cases with the PrimoLinear V-25 food packaging machinery. This bulk net weigher also functions as a box indexing conveyor. The V-25 is conveniently built with controls that interface easily with other machines to provide no container, no fill operation. Consequently, it helps optimize the cycle speed with real-time communication between machines.

The PrimoLinear is easy to operate and clean. It’s perfect for filling trays, plastic bins, or case. The V-25 is designed for free-flowing products, which is why it uses vibration to move a product from one point to another. For every vibrator, there’s a single vibrator pan that’s directly mounted to it. This kind of set up provides operators complete control over the packaging machine.

The vibratory automatic scale uses the 360 Operating Software for a seamless operation. This innovative software comes standard with minute reporting, complete remote operation, and a pre-stored software. Designed with an open-frame style, the PrimoLinear proves that it’s possible to have a clean packaging machine where no bacteria can hide. Combined with a stainless steel frame construction, the V-25 is truly designed with operators in mind.

Thanks to the modular design, as well as an independent floor frame of the PrimoLinear, it can be smoothly integrated with all types of auxiliary packaging equipment and machinery. Our V-25 container filler also comes with handy peripherals like a digital camera, a bar code scanner, and a control panel. The camera is encased with stainless steel for more durable operation and easy servicing. Operators can use the bar code scanner to easily pull up certain recipes. With a durable stainless steel control panel, it can last the harshest environments.