Case Packing vs. Tray Packing: Definitions and Best Use Cases

Product packing is central to every manufacturer. It touches marketing, logistics, and product development, and it can have a huge impact on revenue.

Getting the packing right is crucial, and the first big decision has to do with case packing vs. tray packing.

Here are some details on each option and a helpful guide for choosing which is best for your products.

Tray Packing

Tray packing is a product packing option that consists of a wide, shallow container that is often open at the top—although some tray packing does have a light top flap that serves as a cover. They are commonly made of paperboard, corrugated cardboard, or plastic.

Items are generally placed only one unit deep in each tray.

Types of Tray Packing

There are dozens of styles of tray packing. The most common options are:

- In-fold or beer trays: These broad, shallow trays are made of paperboard and flatten via perforations that allow the side walls to fold in, overlapping at the corners.

- Outfold trays: Outfold trays look and operate similarly to beer trays, except the short side walls fold in while the longer side walls flatten out.

- Locking trays: Locking trays are foldable trays that are cut with tabs and slits that can be folded together to lock the walls into place. Beer trays and outfold trays collapse easily when empty, but locking trays stand secure even before packing.

- Hollow walls: Hollow wall trays are corrugated cardboard trays that fold over on themselves to create additional padding and strength, usually along the two longer sides.

- Produce trays: Produce trays are larger trays with relatively low side walls, generally made of cardboard or plastic. These are stronger and most commonly used for loose produce or clam shells in grocery stores, where they are stacked for consumer access.

- Triangular corner post trays: A sturdier variety of produce tray, triangular corner post trays are also frequently used for produce, but feature reinforced corners for greater durability. Triangular folds in the corners can be flush with the top of the tray or they can extend higher to help stack rigid items with less material.

- Club store trays: Club store trays, or warehouse club trays, are large cardboard trays with up to four windows cut into the sides. These trays were designed for big box stores, and can be printed on to create custom, brand displays.

Case Packing

Case packing is a product packing option that fully and securely encases items. Case packing is generally made from corrugated cardboard, plastic, or wood. Products may be stacked securely within case packing.

Types of Case Packing

There is a case packing style for any product on the market. Of dozens of options, the most common include:

- Regular Slotted Container (RSC): Also known as “Knock Down” cases, these are the most common, and what most people think of as a basic cardboard box. They ship as one layer of corrugated cardboard with four even panels that wrap in to form a box. Outer panels are half the width of the case, so they meet perfectly in the middle to form the top and bottom.

- Half Slotted Container (HSC): An HSC is a corrugated cardboard box with no top. It has one set of outer panels that meet in the middle to form the bottom, but the top is open. They are still considered case packing because the height of the side panels provide complete coverage for products inside.

- Wrap-around: Wrap-around cases include a fifth panel that gets tucked inside one of the case walls. Panels are folded up and around the top, rather than the sides. Where RSC and HSC cases open on the top, then, wrap-around cases open on the sides.

- Harness: Harness-style case packing is a simpler type of five-panel box. The most common is the Center Seam Five Panel Folder, which features two half-panels that meet in the middle at the top of the box.

Case Packing Systems

Case packing options can be selected to open on the top or at one side, so there are a variety of packing systems available to meet either need.

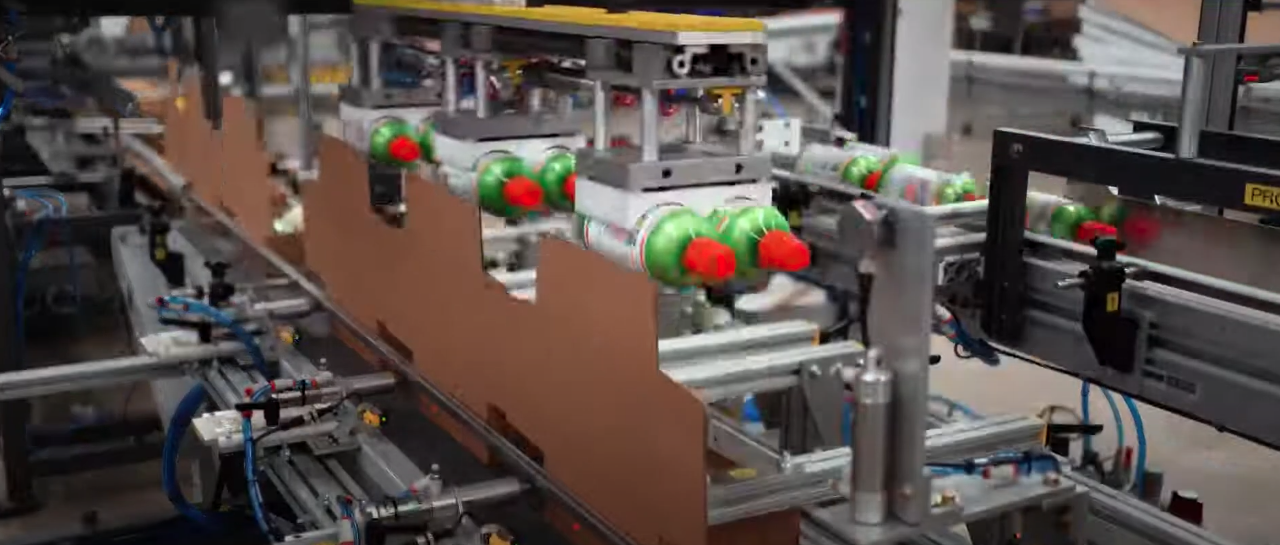

- Top loading systems: Similar to tray packing, some cases are loaded from the top. Pick and place robots or drop packing systems can top-load a variety of case packages with almost any style of product.

- Side loading systems: Also called “horizontal loading,” these systems are helpful for structured products like boxes and jars, rather than bags or soft items. They arrange a collection of products and then push it sideways into the open end of a harness or wrap-around case.

- Bottom loading systems: Bottom loading is ideal for a small number of applications where products remain standing during packing and cannot be securely grabbed from the top. Items such as some drink containers or products with soft plastic covers are ideal for bottom loading systems.

Case Packing vs. Tray Packing

Choosing a packing method for your products is an important decision with far-reaching implications. The packing can impact sales, branding, and more.

Here are the key considerations for choosing case packing or tray packing:

- Protection: Start by determining what level of protection your product needs. Cans of condensed soup, for example, don’t need as much security as bags of potato chips.

- Consumer accessibility: Trays are often used for products that benefit from being displayed quickly. Retail staff can unwrap the plastic covering or remove a top flap, and set trays on shelves or racks for immediate consumer access.

- Cost: Lightweight trays may cost less than full corrugated boxes, but if products are being shipped longer distances, sturdier cases can prevent damage-related loss.

- Sustainability: Trays are generally considered more sustainable, because they use fewer resources and many are made from biodegradable resources.

- Brand: Trays give you more control over display. They can present products in an aesthetic manner that may improve the consumer’s impression of the brand.

In general, then, trays are best for sturdy, uniform products that benefit from quick, well-designed displays. Cases are usually best for items that need more reliable protection and/or are traveling longer distances.

Case and Tray Packing Automation

Most cases and trays can be assembled and packed manually, but pick and place robots combined with case erecting or tray forming machines improve workplace safety and efficiency.

If you’re not sure which option is best for your products, use our free Find My Case Packer tool or get in touch for a free consultation.