Packaging Machine Systems in Ontario

As the most populous and one of the biggest provinces in Canada, Ontario is bursting with things to do for entertainment. Although mostly known for being a hub of activity for politicians and stockbrokers, the province is home to abundant lakes, forests, historical sites, multicultural cities, and lovely small towns. Niagara Falls, for starters, is the most globally recognized destination in the entire country. To get a better understanding of the Canadians, Ottawa is the best place to go. They are a bit reserved, not too ostentatious, but cultured and storied. Ottawa is characterized by the striking Gothic revival architecture of the Parliament buildings, but also has that modest vibe that makes you feel welcome.

Moving to Toronto, you can find one of the premier museums in Ontario, the Royal Ontario Museum with its broad range of collections from around the world. The building is a good combination of old and new architecture, bringing out a unique appearance. Wine tasting should be more than just drinking the delicious nectar. In the Niagara region, you can have the whole wine experience of hopping from one winery to another in a gorgeous setting as you chat with friendly sommeliers. The place is famous for its sweeter ice wines and late harvest wines.

Drop packing for your end-of-line automation

End-of-line automation such as case packers is essential in keeping up with today’s demand and trend as a manufacturer. Given the right system, you can ensure that there are no hold-ups and your products can roll out smoothly of your factory space and loaded into shipping trucks. Drop packing is one of the different types of case packaging systems. This packing technology is typically suited for handling hard plastics, composite containers, and glasses. It’s also far more cost-effective compared to top-loading solutions.

Despite this benefit, drop packer packaging machines are primarily used in the beverage sector with top load case packers replacing them in recent years. That’s because, first, drop packers rely on gravity to load containers, whereas a top load case packing system has more control to ensure smooth loading procedures. Also, while drop packers are initially less costly, they need more maintenance than other systems, thus, increasing the cost over time. That said, drop packers also have benefits.

Provide flexibility

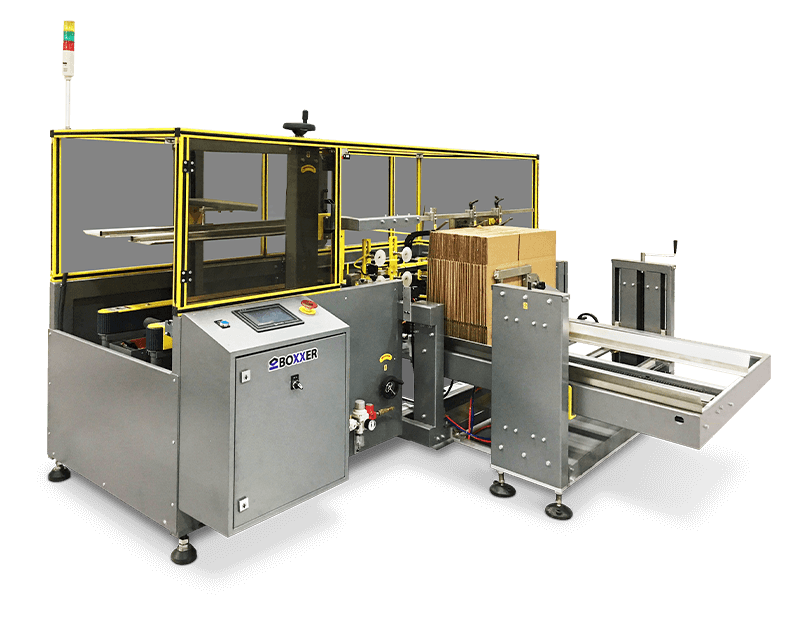

One of the greatest benefits of having a drop packing machine like the Boxxer Drop Packing System from Paxiom is its ability to accommodate a large selection of product shapes, sizes, materials, and weights. That’s because these machines are equipped with adjustable lane guides that allow operators to easily and quickly reconfigure the unit to pack several products on the same line.

Increase productivity

An automated drop packing machine excels at boosting the efficiency of production for any business. As a result, it saves time while also reducing labor costs. Initially, automated packers can be expensive. However, over time, costs are recovered quickly as the machines complete more cycles in less time than the average labor force.

Drop Pack Case Packaging Machine from Paxiom and EndFlex

EndFlex is a Paxiom brand that specializes in designing and manufacturing packaging machines for case erecting, tray forming, cartoning, and case packing. Our automatic and robotic case packers are engineered to cater to the needs of modern packaging. When it comes to packing cases, we have our modular drop packers that can be easily integrated with a case erecting system and can be modified to run a diverse range of products at your desired output. Automatically case packs your bags, pouches, containers, and jugs, our drop packing machine maximizes overall production and reduces labor costs. Its loading system will collate your products and drop pack them into ship-read cases with efficiency and ease.

How it works:

1. Finished products-whether they’re in the form of bags, pouches, or jugs-are indexed and moved to the drop packing area.

2. The products are arranged as per your required pack pattern then staged to be placed on a case.

3. Next, the products are dropped into the case, which has traveled directly below the drop gate, with precision.

4. The products are discharged from the machine in a case and the case will travel further downstream for the case sealing process.

At Paxiom, our packaging machines are engineered and constructed to your every requirement. And for our drop packing solutions, we have equipped them with certain features, while keeping the operator and serving of the machine top of mind. These features include a lane diverter, interlocked doors, an accurate drop gate grid, a color touchscreen, and innovative control panels.