Packing and Packaging Machines For Pennsylvania Businesses

Due to its huge role in building the foundations of the country, Pennsylvania is dubbed as the Keystone State. Its abundance of historic landmarks and attractions also made this namesake even stronger. But apart from the historical significance to the country, the state of Pennsylvania also boasts a beautiful contemporary art scene, food traditions, and unspoiled nature. One of the interesting destinations in this state is Roadside America in Shartlesville. It’s an 8,000 square foot miniature and model railway that offers equal parts of heartwarming and quirky.

Evert tried the famous Philly cheesesteak? If not, then you better grab this chance and head over to Pat’s King of Steaks in Philadelphia. It’s also a perfect place to get a taste of the city’s most famous foods. If you want to spend your night somewhere in the mountains where you can see the Milky Way, the Cherry Springs State Park wouldn’t disappoint. The park is free from light pollution and allows you to see panoramic views from the top of the 2,300-ft mountain. For an exquisite treat for your eyes, visit Longwood Gardens in Kennett Square. It’s one of the best horticultural display gardens in the country where you can see the rarest plants.

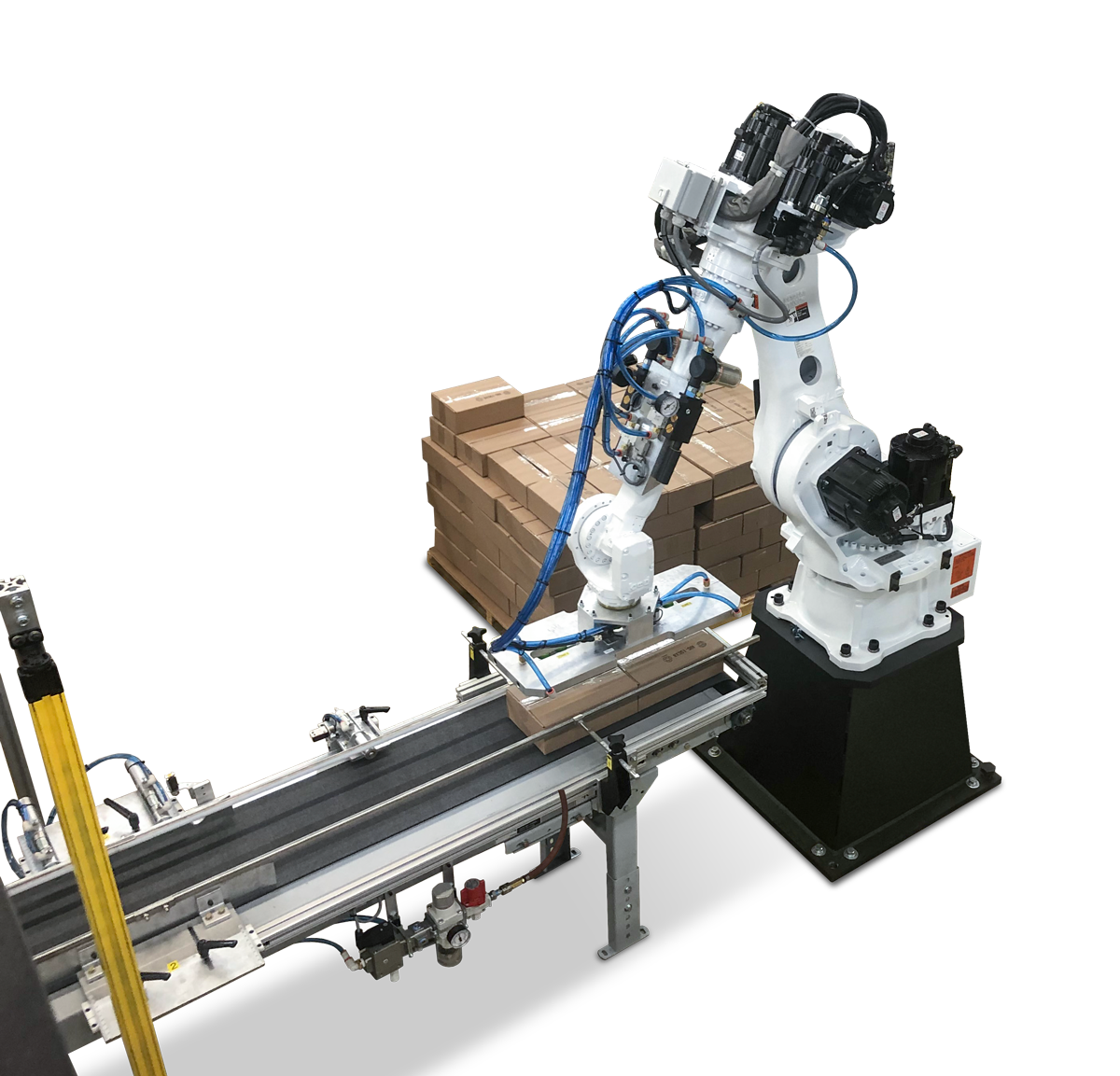

ZZAG Robotic palletizer

Automated palletizing vs robotic palletizing

Automated palletizing is typically achieved by the use of packaging machinery to arrange, line up, and turn the boxes of products as they are on their way down to the conveyor belt. From there, the products are loaded on a pallet and wrapped in plastic. Next, the conveyor belt may move the finished pallet to the loading station and depot it in truck trailers.

While automated palletizing systems can sort and palletize a great number of cartons, they do have downsides. For starters, they occupy a huge space since hundreds of feet of conveyor belts are needed to move and adjust boxes. Moreover, this type of system isn’t that flexible. That’s because product changes and packaging redesigns will need troubleshooting, and sometimes, an overhaul of the automated system.

And so, this is where robotic palletizers come in. Robotic palletizing delivers efficient palletizing of mixed case pallets that have a variety of different products. This packaging machinery also has features of automated palletizing like conveyor belts. Perhaps, the most distinct difference a robotic palletizer has from an automated one is the presence of articulated robot arms at the start or end of the system. This new feature alongside some sensors and analytical algorithms provides a great deal of flexibility that automated palletizers don’t offer.

The robotic Z.ZAG Palletizer

Coming from one of our brand partners, EndFlex, our Paxiom team is proud to introduce our very own robotic palletizing system. Designed to automate your palletizing needs, this packaging machinery is equipped with vacuum generators that work to pick individual cases and place them on a pallet. It’s capable of lifting 40-pound boxes at a mechanical rate of up to 360 boxes per hour.

This machine works by calculating the position of each case as per the desired pattern and case dimensions. Afterwhich the palletizer locates all cases on one pallet then once completed, the machine will fill the next pallet as the first pallet is done. Adding a robotic palletizer at the end of your production line is more economical than using conveyors to move the cases to a costly high-speed palletizer. Our Z.ZAG comes with a compact footprint and is capable of running several pack patterns for interlocked and column-stack configurations. It also features servo drives, PLC controls, and a color touch screen to provide simple and user-friendly setup and operation.

Benefits of using a robotic palletizer

With the increasing preference for lightweight packaging made of reusable and biodegradable materials, manufacturers are now realizing that the use of traditional automated palletizer may not be as reliable as before. Now, robotic palletizer packaging machinery is the new trend, not to mention a better solution. Aside from the high flexibility that robotic palletizers offer, here are their other advantages:

1. Smaller footprint

Compared to conventional palletizing systems, robotic palletizers take up much less space, making it perfect for small-scale facilities where palletizing is of great importance.

2. Modular design

With its robotic arms that fit in smaller areas, a robotic palletizer is far more modular than the traditional automated palletizer. Plus, several robotic arms can also be set up to work simultaneously on the same or different product line(s).

3. Scalability

Thanks to its modular design, robotic palletizers can be scaled up to achieve the demand for new product lines. They can also be easily stopped in times of slow demands.