Packaging Machines for Arkansas

Arkansas prides itself on being the world capital of several things like quarts, folk music, and archery bow production. Its abundant attractions and activities will surely channel your adventurous side you never knew you had. Mostly known as a quiet and scenic state, Arkansas is often overlooked by many travelers as they go straight to more well-known destinations. Truth is, Arkansas is a haven to outdoor and nature lovers. It has some of the amazingly preserved parks, million acres of national forests, and sublime tapestry of farmland, serene pastures, beautiful mountain vistas, and other spectacular natural wonders.

Start your day outdoors by going to Buffalo National River that’s flanked by striking limestone bluffs and dotted with dozens of waterfalls. Whether you want to hike, camp, kayak, raft, or just soak up this unspoiled wilderness, it’s all up to you. Tucked away in a peaceful woodland at Eureka Springs is the Thorncrown Chapel. This majestic church is made almost entirely of organic materials found in the surrounding wilderness. To get a taste of Arkansas’s downtown life, visit Dickson Street at Fayetteville. It’s the hub of culture and live entertainment and is home to several bars, restaurants, galleries, and boutiques.

Bottle Unscrambler as part of the Packaging Line

What does a bottle unscrambler do? How does it benefit your business? This type of packaging machinery is especially handy for production lines that handle a large volume of containers that need to be organized efficiently. As its name suggests, it works by sorting and unscrambling containers that are stored in a supply hopper and proceed to arrange them in various groups. This is done to prepare the bottles for use along with a production line conveyor system where each container is filled, decorated, and/or placed into cases or cartons.

Bottle unscramblers work best on a wide selection of containers and bottles, including those used in the food and beverage, household, cosmetic, pharmaceutical, and chemical industries. For example, products like bottled water, detergents, lotions, dairy products, motor oil, and many more, use bottle unscramblers since they often come in different size bottles.

Major Points About Bottle Unscrambling Machines

1. Bottle Unscramblers operate by segregating and sorting all types of containers into their designated shapes and sizes. These unsorted containers are all lumped together in the hopper and once sorted, they’ll be sent onto the various parts of the production line.

2. This piece of packaging machinery has a wide use among several industries, the most common among are cosmetic, food, nutraceutical, and pharmaceutical.

3. These machines function to effectively provide fast production rates by accurately dispersing containers to simplify production and lower costs, particularly as opposed to a manual bottle unscrambling process.

Paxiom Group for your Bottle Unscrambling needs

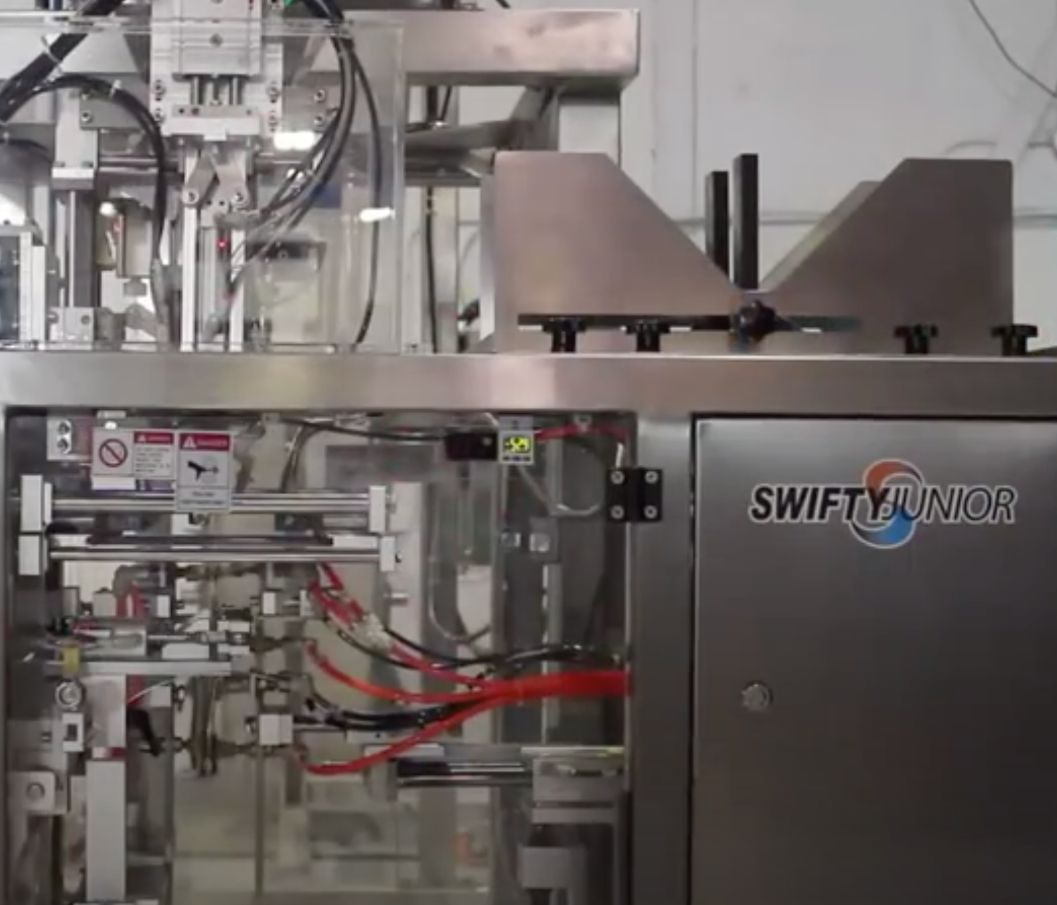

We are a global manufacturer of packaging machinery that provides the broadest collection of all types of equipment and machines used in packaging lines. As part of our products, we have engineered our very own Bottle Unscrambling Machine under ValTara Technology–a brand known as one of the industry leaders in the packaging industry. Officially named as ValTara Container Unscrambling machine, it’s equipped with an operator-friendly system to allow a seamless transfer of bottles from the supply store to an indexing conveyor for filling and the succeeding packaging processes.

More importantly, this packaging machine promotes excellent hygiene since it doesn’t require any human intervention. In other words, the ValTara Bottle Unscrambling Machine greatly reduces the risk of bacteria growth and cross-contamination.

How a Bottle Unscrambler helps businesses

Designed for easy integration, these packaging systems often deliver high efficiency and simplicity while also being versatile enough to accommodate many types of containers in different shapes and sizes. What’s more, all those things can be accomplished without needing to halt the process and do a change-over. Furthermore, bottle unscramblers can be synchronized with labelers, filling machines, and in some cases, automatic assembly machines.

Simply put, it can boost your business’s productivity and convenience, since it doesn’t further complicate your production line nor require hefty capital expenditure. Another perk is that your performance quality won’t be compromised while dealing with new bottle sizes, something that often occurs in several industries as manufacturers decide to revamp their packaging over time. As a result, you can keep costs down while ensuring that you aren’t losing money to another business that can offer new container types. With a bottle unscrambler, you won’t need to separate containers through a manual process because this packaging machine can unscramble tens to hundreds of bottles per minute with precision.